Power generating boiler main steam temperature control method and system based on multivariable decoupling

A multi-variable decoupling technology for power generation boilers, which is applied in the field of combustion optimization of thermal power boilers, can solve the problems of strong case-specificity, water pipe pressure drop and rise, etc., and achieve the goal of improving operation economy, reducing work intensity and strong stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

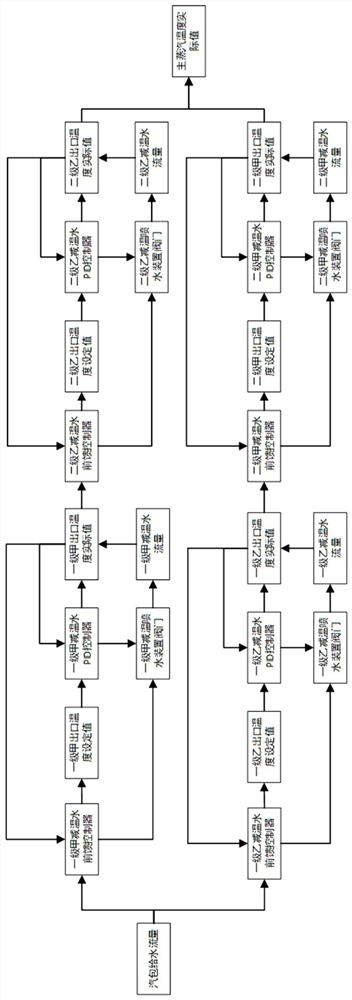

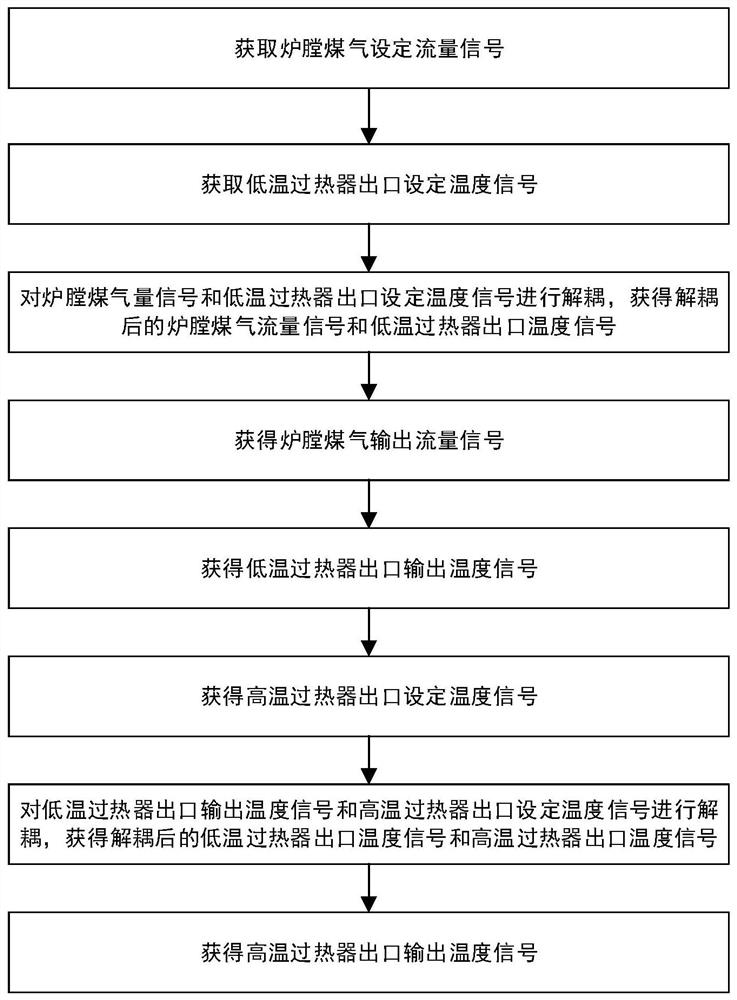

[0035] A method for controlling the main steam temperature of a thermal power boiler. Firstly, the acquired signal is decoupled, and the decoupled output signal is adjusted and controlled by a feedforward-feedback composite controller, and then the output signal is controlled by adjusting the signal inlet valve. Such as figure 1 The schematic diagram of the main steam temperature control structure of the boiler shown in the boiler steam-water system is generally divided into two lines A and B for controlling the main steam temperature. The two lines have the same structure. This embodiment uses one line as an example for specific description.

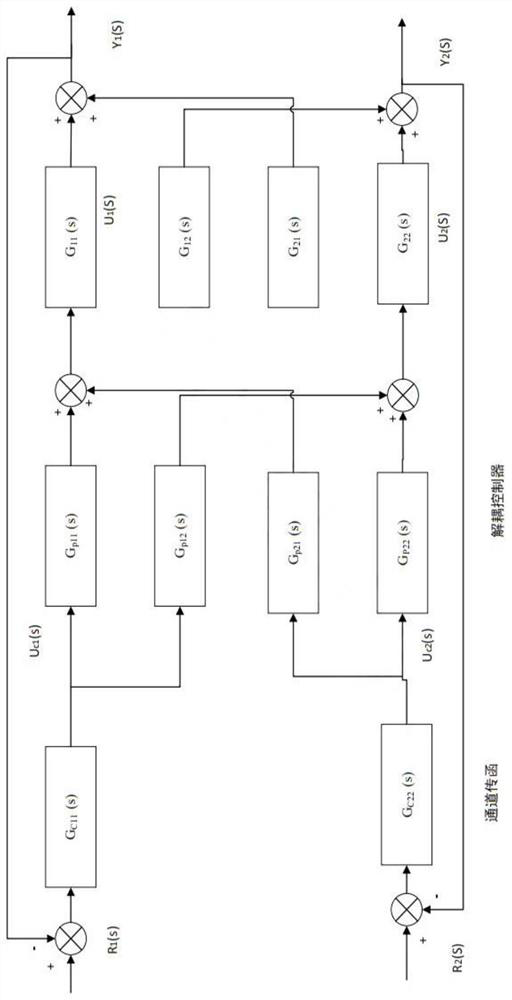

[0036] Furnace gas volume will affect the temperature of the low-temperature superheater and the temperature of the high-temperature superheater, that is, it will have a coupling effect on the main steam temperature of the outlet temperature of the low-temperature superheater and the main steam temperature of the high-temperature superhe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com