System and method for controlling comprehensive parameters in sintering machine flue gas hood

A technology of comprehensive parameters and control systems, applied in furnace control devices, waste heat treatment, charging treatment types, etc., can solve the problems of unstable parameter control, increase production costs, and affect the quality of sintered finished ore.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0090] In order to describe the present invention clearly, in detail and completely, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

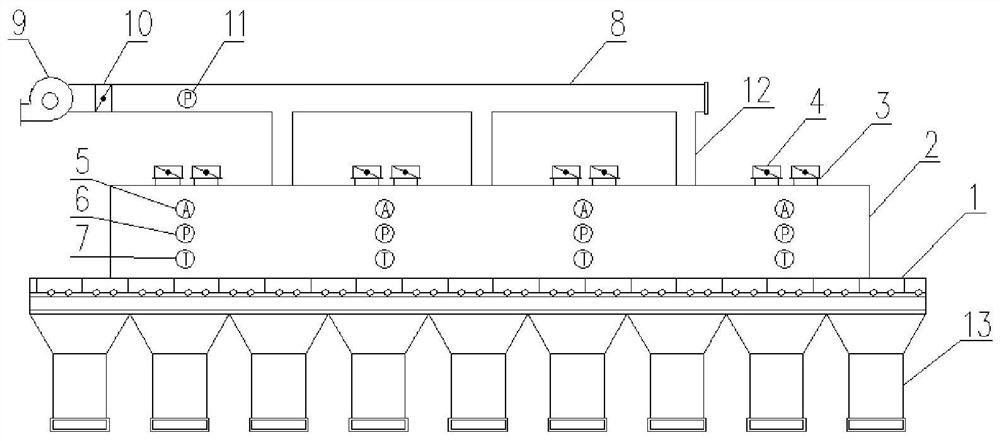

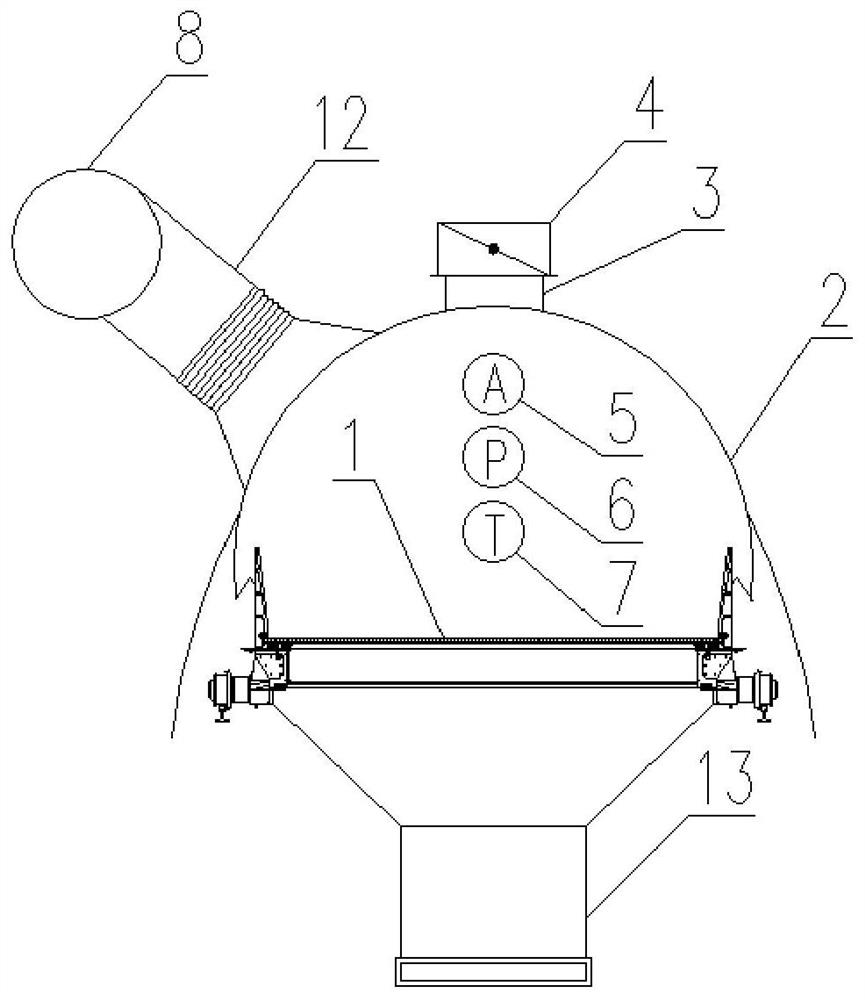

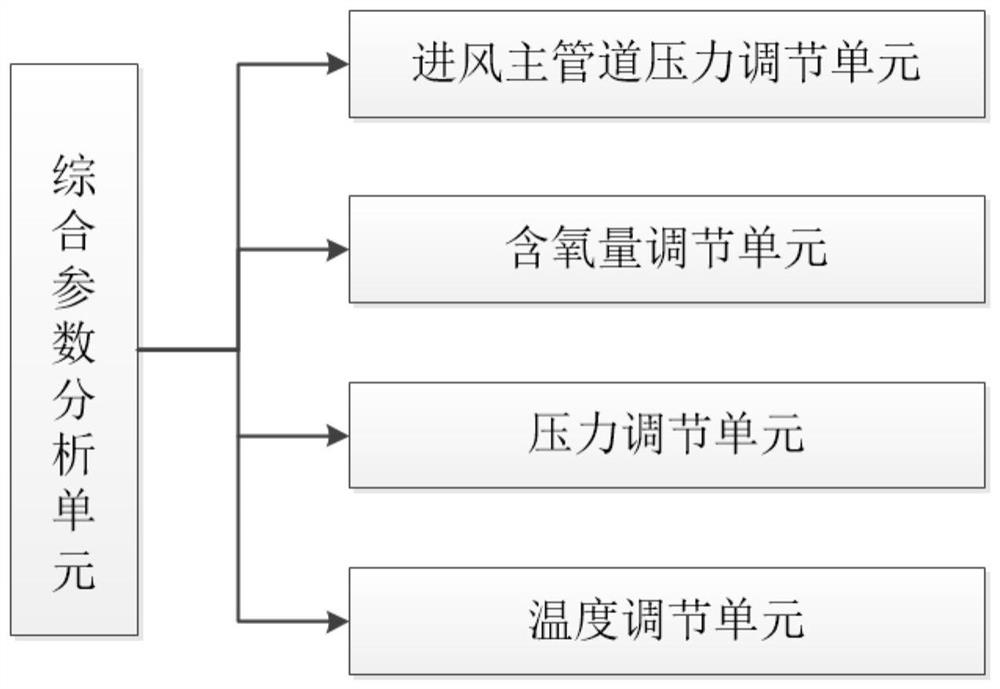

[0091] Such as figure 1 and figure 2 As shown, a comprehensive parameter control system in a fume hood of a sintering machine according to the present invention includes a trolley 1, a fume hood 2 arranged above the trolley 1, and an air outlet corresponding to the fume hood arranged below the trolley 1. Pipeline 13, the air inlet branch pipe 12 arranged above the flue gas hood 2, the air inlet main pipe 8 connected to the air inlet branch pipe 12, the circulation fan damper 10, the circulation fan 9, the logic controller and the computer software system, its characteristics That is, multiple sets of air intake regulating pipes 3 are arranged at equal intervals on the top of the fume hood 2, and an air intake regulating valve 4 is arranged at the upper end of the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com