Welding forming method of wrench mold

A welding molding and mold technology, applied in the field of wrench molds, can solve the problems of mold scrapping and high price of hot mold steel, and achieve the effects of low manufacturing cost, long service life and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

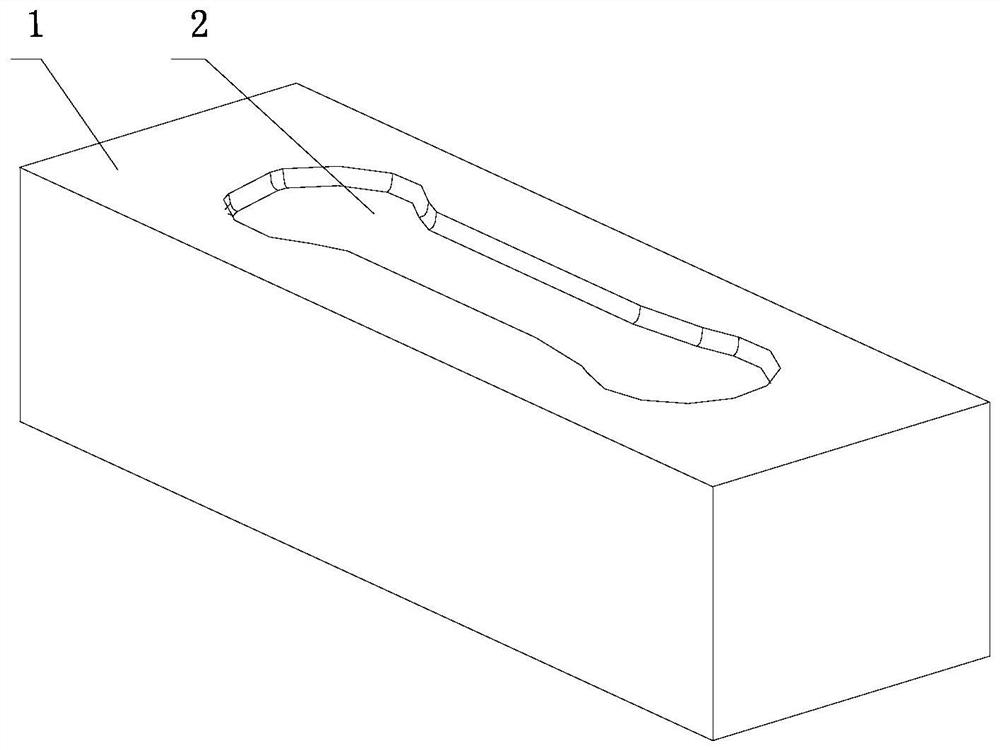

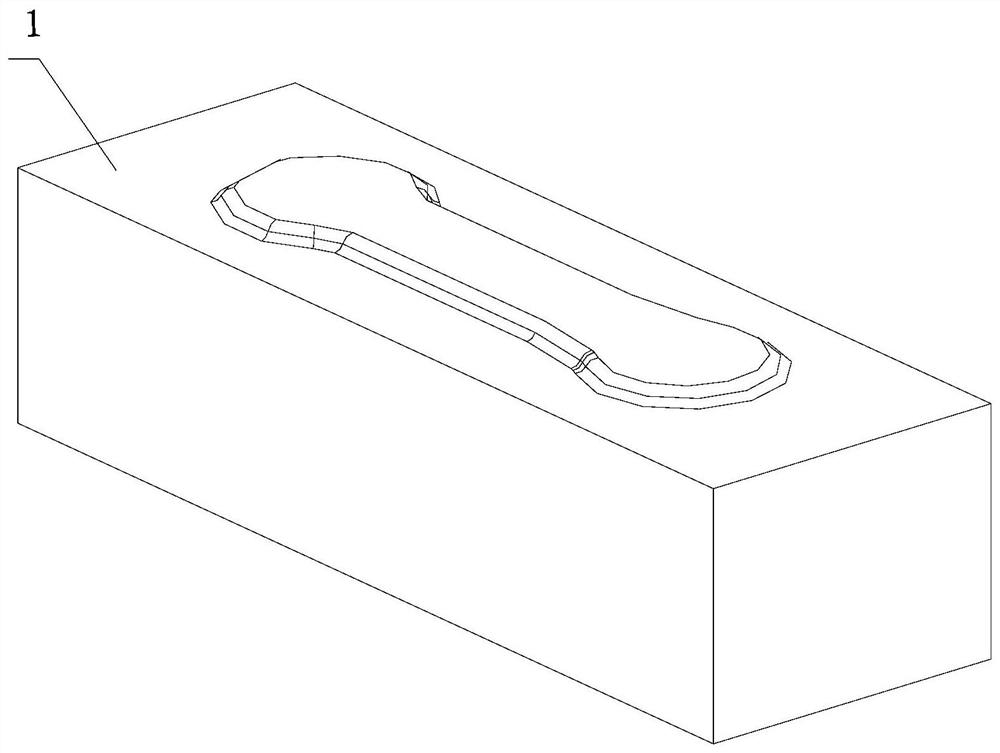

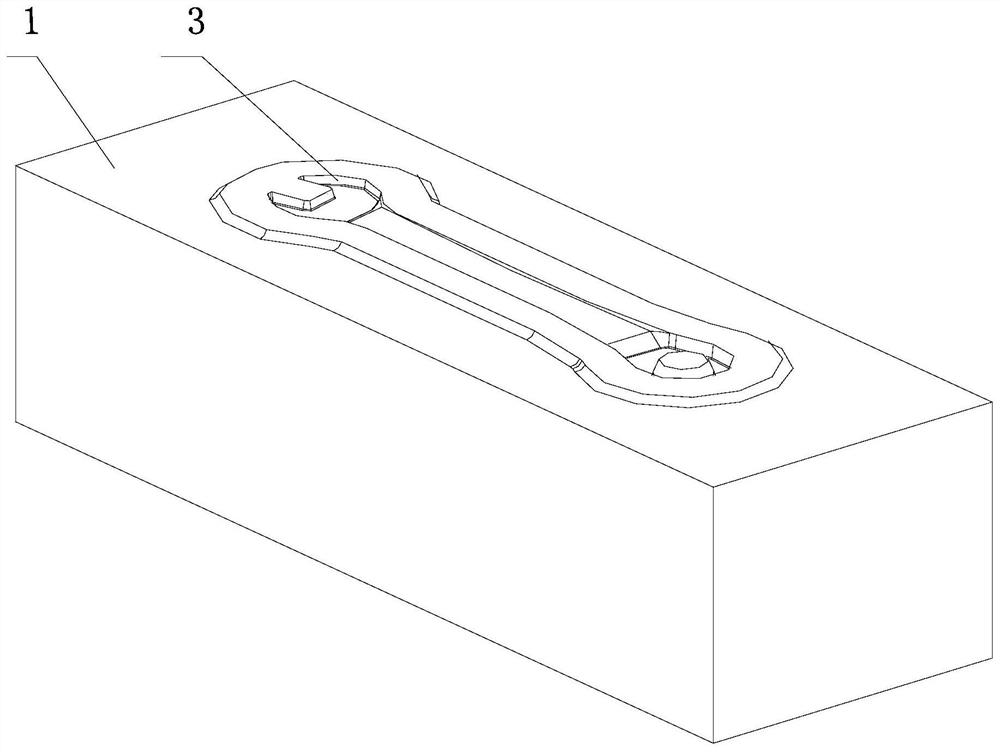

[0024] The invention is like Figure 1-3 Shown; a welding forming method of a wrench mold, which includes the following steps:

[0025] Step 1), blanking: select the material and size of the blank according to the requirements of the drawing to form the blank;

[0026] Step 2) Annealing: Put the billet in step 1) into an annealing furnace and heat it to a temperature of 800°C-900°C, keep it for 18 hours, and then cool it down in the furnace; the hardness of the billet after annealing is ≤229HB;

[0027] Step 3). Preliminary machining: Machining the blank material annealed in step 2) to achieve the required shape of the design; through machining, determine the shape of the final mold;

[0028] Step 4), quenching and tempering (tempering treatment): the hardness of the blank material processed in step 3) is 42HRC-48HRC; the mold has certain strength and toughness;

[0029] 1) Quenching: The billet is heated to a temperature of 750°C-800°C in a vacuum furnace and then kept for 0.5 hours, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com