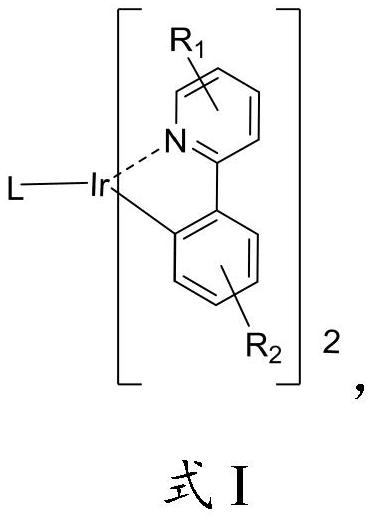

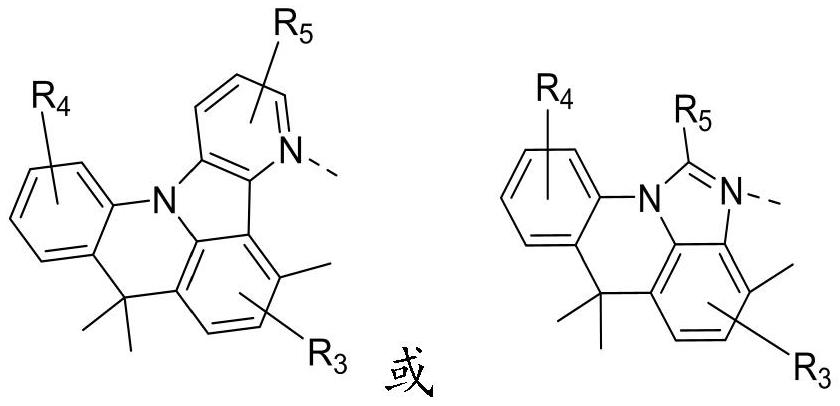

Organic metal iridium complex as well as preparation method and application thereof

A technology of iridium complexes and organometallics, which is applied in the fields of indium organic compounds, platinum group organic compounds, organic chemistry, etc., can solve the problems of low lifespan, complicated and time-consuming synthesis process of phosphorescent materials, etc., and achieve long service life, electric High luminescence efficiency, simple and efficient process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

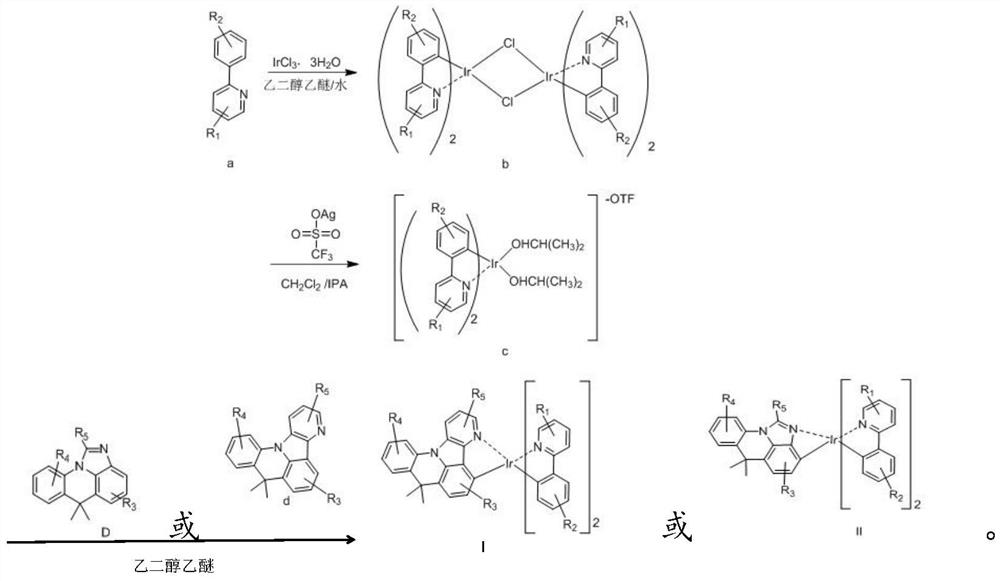

Method used

Image

Examples

Embodiment 1

[0052]

[0053] (1) Synthesis of intermediate b-2: Add reactant a-2 (56mmol) and iridium trichloride (24mmol) into a three-necked flask, then add 200mL of ethylene glycol ether and 100mL of water, and raise the temperature under nitrogen protection The reaction was stirred at 140°C for 24 hours. After the reaction was completed, the temperature was lowered, and the yellow solid was obtained by direct suction filtration, which was first washed with 100 mL of ethanol, and then washed with 100 mL of petroleum ether, and dried to obtain intermediate b-2 (10.8 g, yield 80%).

[0054] (2) Synthesis of intermediate c-2: Weigh intermediate b-2 (9mmol), add silver trifluoromethanesulfonate (27mmol), then add 100mL of dichloromethane to the system, add 40mL of isopropanol, nitrogen Under protection, react at room temperature for 24 hours. TLC monitoring showed that the reaction of the raw materials was basically completed, and a dark solution was obtained by suction filtration, whic...

Embodiment 2

[0059]

[0060] (1) Synthesis of intermediate b-9: Add reactant a-2 (56mmol) and iridium trichloride (24mmol) into a three-necked flask, then add 200mL of ethylene glycol ether and 100mL of water, and raise the temperature under nitrogen protection The reaction was stirred at 140°C for 24 hours. After the reaction was completed, the temperature was lowered, and the yellow solid was obtained by direct suction filtration, which was first washed with 100 mL of ethanol, then washed with 100 mL of petroleum ether, and dried to obtain intermediate b-9 (12.2 g, yield 81%).

[0061] (2) Synthesis of intermediate c-9: Weigh intermediate b-9 (9mmol), add silver trifluoromethanesulfonate (27mmol), then add 100mL of dichloromethane to the system, add 40mL of isopropanol, nitrogen Under protection, react at room temperature for 24 hours. TLC monitoring showed that the reaction of the raw materials was basically completed, and the dark solution was obtained by suction filtration, and sp...

Embodiment 3

[0066]

[0067] (1) Synthesis of intermediate b-22: Add reactant a-22 (56mmol) and iridium trichloride (24mmol) into a three-necked flask, then add 200mL of ethylene glycol ether and 100mL of water, and raise the temperature under nitrogen protection The reaction was stirred at 140°C for 24 hours. After the reaction was completed, the temperature was lowered and filtered with suction to obtain a yellow solid, which was washed with 100 mL of ethanol and then with 100 mL of petroleum ether, and dried to obtain intermediate b-22 (14.7 g, yield 83%).

[0068] (2) Synthesis of intermediate c-22: Weigh intermediate b-22 (9mmol), add silver trifluoromethanesulfonate (27mmol), then add 100mL of dichloromethane to the system, add 40mL of isopropanol, nitrogen Under protection, react at room temperature for 24 hours. TLC monitoring showed that the reaction of the raw materials was basically completed, and a dark solution was obtained by suction filtration, and spin-dried to obtain i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com