A kind of preparation method of imitation tobacco leaf type reconstituted tobacco leaf

A technology for reconstituting tobacco leaves and tobacco leaves, which is applied in the directions of preparation of tobacco, tobacco, and application, and achieves the effects of being easy to accept, improving the phenomenon of sliding sheets, and having a simple and feasible method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

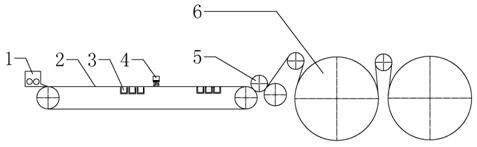

Image

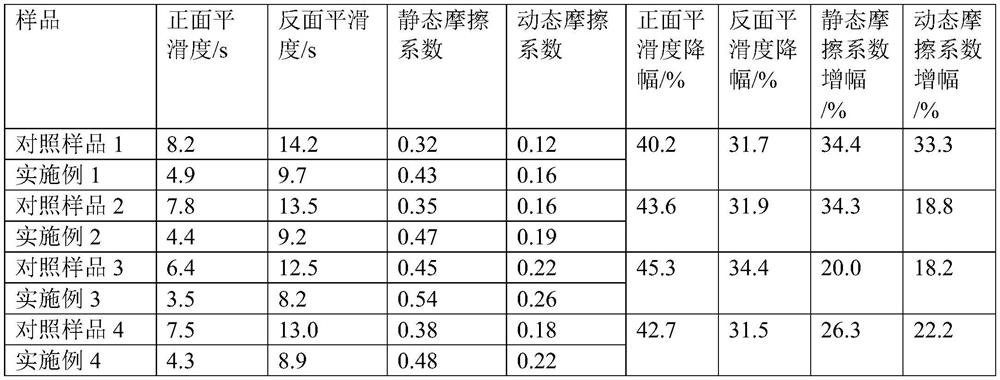

Examples

Embodiment 1

[0034] (1) Tobacco stems and tobacco fragments were mixed into plant raw materials at a mass ratio of 1:1, then soaked in 60°C hot water with a mass ratio of 5 times, and extracted twice by continuous countercurrent extraction, each time for 30 minutes, using The method of centrifugal separation separates solid and liquid to obtain plant extract and plant fiber;

[0035] (2) The plant extract obtained in step (1) is filtered successively with 60 mesh and 300 mesh filter screens to remove the tiny plant raw materials remaining therein, and the filtered plant extract adopts vacuum decompression concentration at a temperature of 70 °C, under the condition of a vacuum of 85kPa, it is concentrated into a concentrated solution with a density of 1.15g / ml through a concentration pot, and then a 3% tobacco flavor is added to make a coating solution;

[0036] (3) adding the plant fiber obtained in step (1) to normal temperature water to make its concentration reach 3%, beating through a...

Embodiment 2

[0044] (1) Mix lotus leaves and perilla leaves at a mass ratio of 1:1 to form plant materials, then soak them in 70°C hot water with a mass ratio of 6 times, and extract twice by continuous countercurrent extraction, each time for 40 minutes , adopting the method of centrifugal separation to separate solid and liquid to obtain plant extract and plant fiber;

[0045] (2) The plant extract obtained in step (1) is filtered successively with 60 mesh and 300 mesh filter screens to remove the small plant raw materials remaining therein, and the filtered plant extract adopts the method of vacuum decompression concentration at a temperature of At 70°C and a vacuum of 85kPa, it is concentrated into a concentrated solution with a density of 1.15g / ml through a concentration pot, and then a 3% tobacco flavor is added to make a coating solution;

[0046] (3) adding the plant fiber obtained in step (1) to normal temperature water to make its concentration reach 3%, beating to a beating degr...

Embodiment 3

[0052] (1) Perilla leaves are used as plant raw materials, soaked in 60°C hot water at a mass ratio of 1:7 times, extracted twice by continuous countercurrent extraction, 40min each time, and separated from solid and liquid by centrifugation Obtain plant extract and plant fiber;

[0053] (2) The plant extract obtained in step (1) is filtered successively with 60 mesh and 300 mesh filter screens to remove the tiny plant raw materials remaining therein, and the filtered plant extract is concentrated in vacuum in a vacuum. The temperature is 70°C, and the vacuum degree is 85kPa. It is concentrated into a concentrated solution with a density of 1.18g / ml through a concentration pot, and then a 3% tobacco flavor is added to make a coating solution;

[0054] (3) adding the plant fiber obtained in step (1) to normal temperature water to make its concentration reach 3%, beating through a disc refiner to a beating degree of 25 ° SR, and a wet weight of 3.5g plant pulp;

[0055] (4) The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com