A method for preparing ceramsite from oily sludge

A technology of oil sludge and ceramsite, applied in the application, ceramic products, clay products and other directions, can solve the problems of complex composition, high stability, and improper placement, etc., to promote development, reduce treatment costs, and achieve great economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A kind of method utilizing oily sludge to prepare ceramsite, comprises the following steps:

[0044] (1) Selection of raw materials and pretreatment of raw materials;

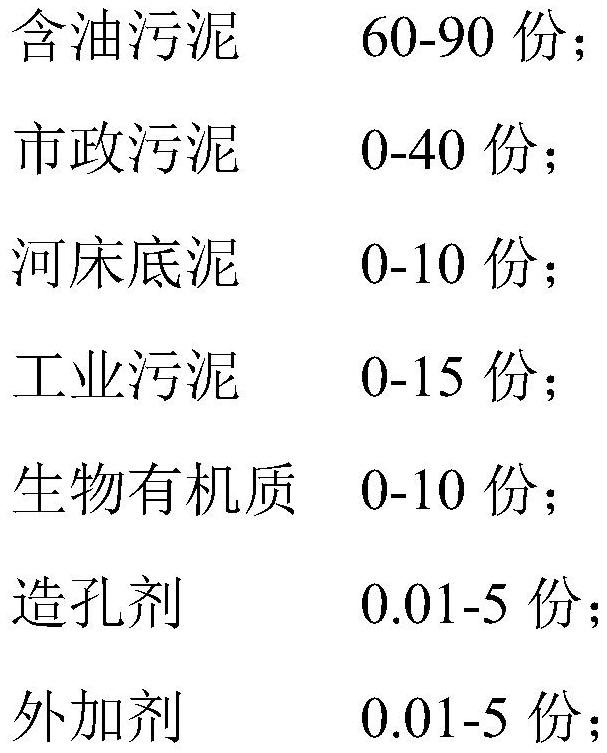

[0045] The raw materials include oily sludge, auxiliary sludge, bio-organic matter, pore-forming agents and additives;

[0046] The auxiliary sludge includes municipal sludge, river bed sludge and industrial sludge, and the particle size of the sludge is less than 0.5mm; the water content of the oily sludge is 10%-40% and the oil content is lower than 10% %, the water content of municipal sludge, river bed sludge and industrial sludge is 10%-98%;

[0047] The specific oily sludge refers to the 071-001-08 oily sludge produced by petroleum mining and refining in the HW08 waste mineral oil and mineral oil-containing waste in the "National Hazardous Waste List (Revised Draft)" (Draft for Comment) Heyoujiao, 071-002-08 Drilling mud prepared with mineral oil as a continuous phase for drilling cuttings and wa...

Embodiment 2

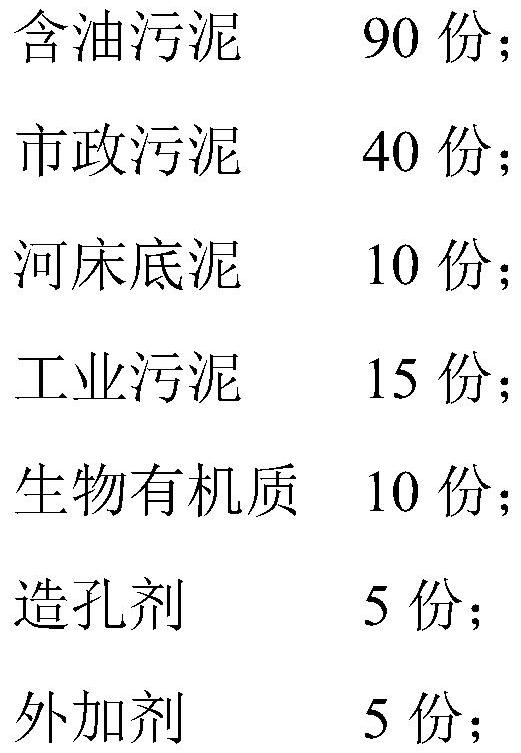

[0074] The difference between the present embodiment and embodiment 1 is only that the parts by weight of each component of the mixture are:

[0075]

[0076]

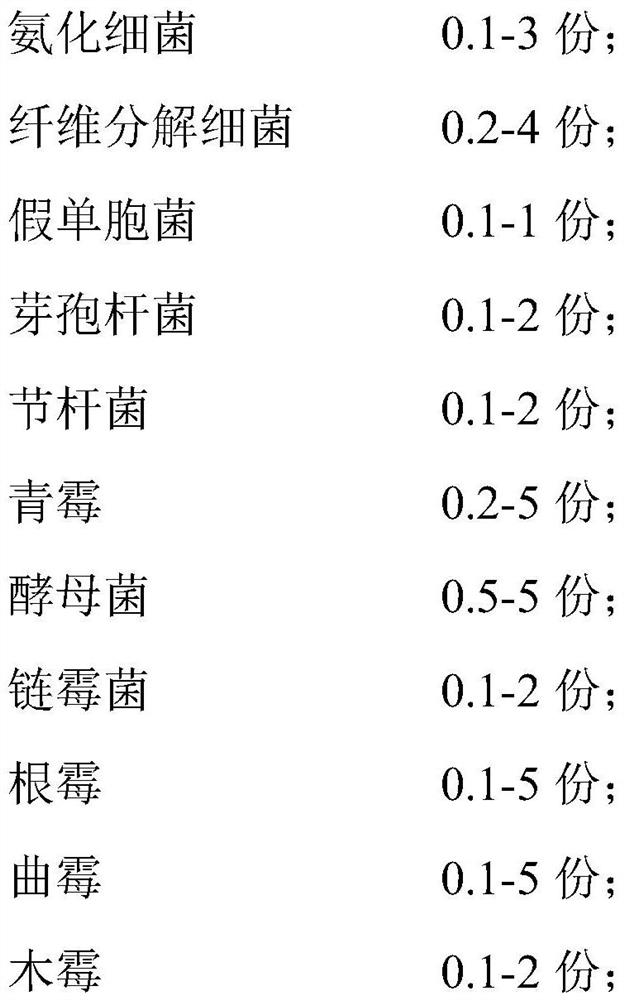

[0077] The parts by weight of each component of mixed bacterial agent are:

[0078]

[0079] The weight of the aging bacterial agent sprayed during one stirring is 0.38% of the total weight of raw materials.

[0080] The aging time is 12 hours.

Embodiment 3

[0082] The difference between the present embodiment and embodiment 1 is only that the parts by weight of each component of the mixture are:

[0083] 60 parts of oily sludge;

[0084] 0.01 part of pore forming agent;

[0085] Admixture 0.01 part;

[0086] The parts by weight of each component of mixed bacterial agent are:

[0087]

[0088]

[0089] The weight of the aging bacterial agent sprayed during one stirring is 0.15% of the total weight of raw materials.

[0090] The aging time is 24 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com