Purification method of cannabidiol

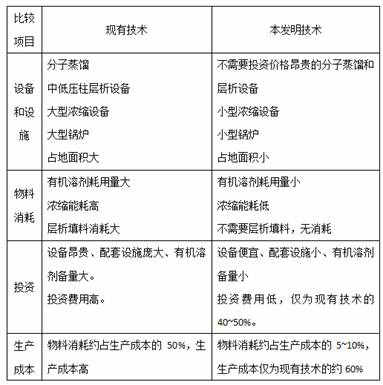

A purification method and technology of cannabidiol, applied in the field of biochemical industry, can solve the problems of high production cost and large investment of cannabidiol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take 100g of ethanol crude extract of industrial hemp with 16.2% cannabidiol content, heat and reflux with 300ml of ethanol at 80°C for 20 minutes, after dissolving, add 3200ml of sulfuric acid aqueous solution with pH=4, stir at 120r / min for 10 minutes, let stand After 8 hours, divide the dehydration solution to obtain 510ml of precipitation solution; add 3200ml of sodium hydroxide aqueous solution with pH=10 to the above precipitation solution, stir at 120r / min for 10 minutes, let stand for 12 hours, and divide the dehydration solution to obtain 480ml of precipitation solution ; Add 3800ml of purified water to the above precipitation solution, stir at 120r / min for 10 minutes, let it stand for 12 hours, filter the dehydrated solution, and obtain 134g of aqueous precipitation; add 550ml of absolute ethanol to the above precipitation, heat at 70°C and 120r / min Stir for 15 minutes, after dissolving, let stand at 5°C for 6 hours, remove the insoluble matter by filtration, s...

Embodiment 2

[0025] Take 100g of methanol crude extract of industrial hemp with 16.5% cannabidiol content, heat and reflux with 400ml of methanol at 70°C for 30 minutes, after dissolving, add 5000ml of nitric acid aqueous solution with pH=4.5, stir at 120r / min for 10 minutes, let stand After 10 hours, divide the dehydration solution to obtain 490ml of precipitation solution; add 3000ml of potassium hydroxide aqueous solution with pH=11 to the above precipitation solution, stir at 120r / min for 15 minutes, let stand for 12 hours, and divide the dehydration solution to obtain 450ml of precipitation solution ; Add 3500ml of purified water to the above precipitate, stir at 120r / min for 10 minutes, let it stand for 12 hours, filter or centrifuge to separate the dehydrated liquid, and get 105g of aqueous precipitate; add 400ml of methanol to the above precipitate, heat at 70°C and 120r / min Stir for 10 minutes, after dissolving, let it stand at 0°C for 4 hours, filter or centrifuge to remove insolu...

Embodiment 3

[0027] Take 100g of 6# solvent oil crude extract of industrial hemp with a cannabidiol content of 15.8%, heat and reflux with 500ml acetone at 60°C for 30 minutes, after dissolving, add 5500ml of nitric acid aqueous solution with pH=3.5, and stir at 120r / min for 10 minutes , stand still for 12 hours, divide the dehydration liquid to obtain 485ml of precipitation solution; add 3500ml of lithium hydroxide aqueous solution with pH=10 to the above precipitation solution, stir at 120r / min for 15 minutes, let stand for 12 hours, and divide the dehydration liquid to obtain 430ml of precipitation solution; add 4500ml of purified water to the above precipitation solution, stir at 120r / min for 10 minutes, let it stand for 12 hours, filter the dehydrated solution, and obtain 103g of aqueous precipitation; add 500ml of acetone to the above precipitation, heat at 60°C and 120r / min Min and stirred for 10 minutes, after dissolving, stand at 10°C for 10 hours, filter to remove insoluble matter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com