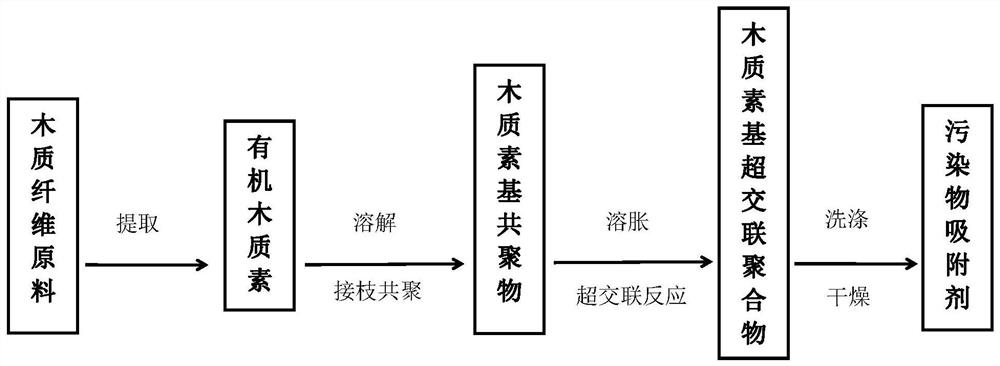

Lignin-based super-crosslinked polymer with hierarchical pore structure, and preparation method and adsorption application thereof

A lignin-based, polymer technology, used in chemical instruments and methods, other chemical processes, etc., can solve problems such as the need to improve adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

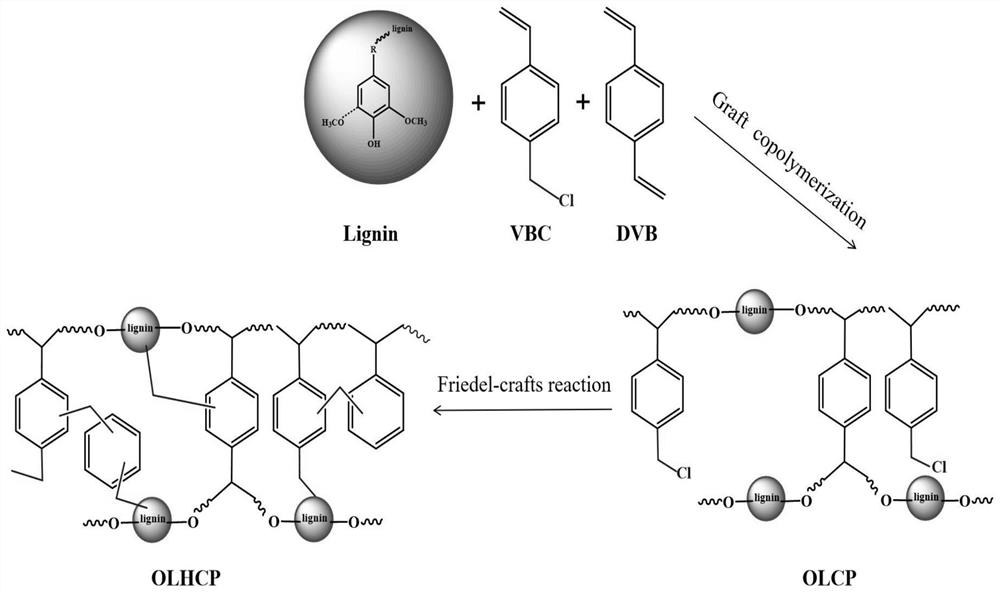

[0075] For the preparation of lignin-based graft copolymer (OLCP), 0.25g ethanol-extracted lignin (organic lignin in Table 1) was dissolved in 25mL ethyl acetate, filtered through a 0.45um filter, and the filtrate was loaded into a three-necked flask, and placed in In the filtrate, according to the mass ratio of lignin: chloromethyl styrene: p-divinylbenzene = 1:14:4, add monomer and crosslinking agent, then add 0.1g azobisisobutylcyanide as initiator, pass into Nitrogen, reacted at 85°C for 6h, solids precipitated out, washed with ethanol and water alternately for 3 times after cooling, and vacuum-dried at 60°C for 1 day to obtain a lignin-based graft copolymer (OLCP), which was named OLCP1. Measured by contact angle ( Figure 5 ) exhibits controllable hydrophobic properties.

[0076] For the preparation of lignin-based hypercrosslinked polymer (OLHCP), 3 g of lignin graft copolymer (OLCP1) was used as a precursor for Friedel-Crafts reaction, that is, swelling in 30 mL of 1,...

Embodiment 2

[0079] For the preparation of lignin-based graft copolymer (OLCP), 0.5g of ethanol-extracted lignin (organic lignin in Table 1) was dissolved in 25mL of ethyl acetate, filtered through a 0.45um membrane filter, and the filtrate was loaded into a three-necked flask In the filtrate, add monomer and crosslinking agent according to the mass ratio lignin: chloromethylstyrene: p-divinylbenzene=1:7:2, then add 0.2g azobisisobutylcyanide as initiator, Nitrogen gas was introduced and reacted at 85°C for 8 hours. Solids precipitated out. After cooling, they were washed alternately with ethanol and water three times, and vacuum-dried at 60°C for 1 day to obtain a lignin-based graft copolymer, which was named OLCP2. Measured by contact angle ( Figure 5 ) exhibits controllable hydrophobic properties.

[0080] For the preparation of lignin-based hypercrosslinked polymer (OLHCP), 3 g lignin graft copolymer (OLCP2) was used as a precursor for Friedel-Crafts reaction, that is, swelling in 30...

Embodiment 3

[0083] Preparation of lignin-based graft copolymer (OLCP), 0.75g of ethanol-extracted lignin (organic lignin in Table 1) was dissolved in 25mL of ethyl acetate, filtered through a 0.45um membrane filter, and the filtrate was loaded into a three-necked flask , in the filtrate by mass ratio lignin: chloromethyl styrene: p-divinylbenzene=1:5:1 add monomer and crosslinking agent, then add 0.4g azobisisobutylcyanide (AIBN) initiator , fed nitrogen, reacted at 85°C for 10h, solids precipitated out, washed with ethanol and water alternately three times after cooling, and dried in vacuum at 60°C for 1 day to obtain a lignin-based graft copolymer, which was named OLCP3. Measured by contact angle ( Figure 5 ) showed controllable hydrophobic properties.

[0084] For the preparation of lignin-based hypercrosslinked polymer (OLHCP), 3 g of lignin graft copolymer (OLCP3) was used as a precursor to carry out Friedel-Crafts reaction, that is, to swell overnight in 30 mL of 1,2-dichloroethan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com