A kind of amphiphilic montmorillonite and its preparation method and application

A montmorillonite and amphiphilic technology, applied in the field of oil displacement, can solve problems such as harsh conditions, difficult production, cumbersome industrial production, etc., to maintain temperature and salt resistance, stability and repeatability, and good oil displacement effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

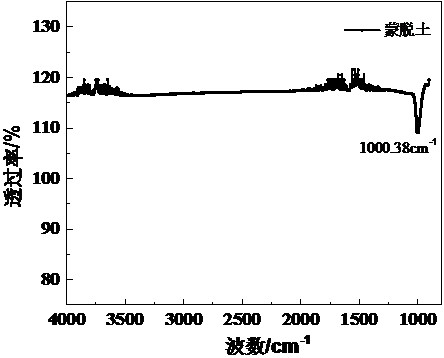

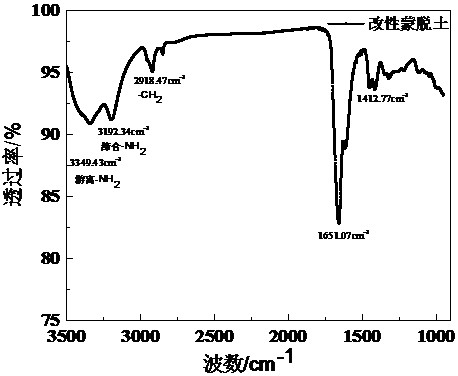

Image

Examples

Embodiment 1

[0074] Example 1 Preparation of amphiphilic montmorillonite

[0075] Step (1) Weigh 2g of montmorillonite into a 1L beaker containing 900mL of water, and mechanically stir at 500 revolutions for 15min to obtain a montmorillonite dispersion (mixture I) with a particle size of 60nm;

[0076] Step (2) Prepare 80 mL of hydrophilic monomer solution (mixed solution II): Weigh 30 g of hydrophilic monomer acrylamide (2:30 mass ratio to montmorillonite) and dissolve it in 80 mL of deionized water. Stir until completely dissolved;

[0077] Step (3) Prepare 20 mL of initiator solution: Weigh 0.3 g of initiator potassium persulfate (1% of the mass of the hydrophilic monomer) and dissolve it in 20 mL of deionized water;

[0078] Step (4) Put the mixed solution I obtained in step (1) and the mixed solution II obtained in step (2) into a 2L clean two-neck round-bottomed flask, insert a stirring paddle to seal the main bottle mouth, and pass N from the side opening. 2 , exhaust oxygen for 3...

Embodiment 2

[0085] The preparation method is the same as that in Example 1, the only difference is that in step (1), mechanical stirring is carried out at 400 revolutions for 30 minutes to obtain a montmorillonite dispersion with a particle size of 200 nm.

Embodiment 3

[0087] The preparation method is the same as that in Example 1, the only difference is that in step (1), mechanical stirring is carried out at 250 rotation speed for 60 min to obtain a montmorillonite dispersion liquid with a particle size of 300 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com