Intermetallic compound and carbonitride co-hardened powder metallurgy high-speed steel and preparation method thereof

A technology of intermetallic compounds and carbonitrides, applied in the field of machining tools, can solve the problems of excessive grain size, hindering grain growth, low hardness and wear resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

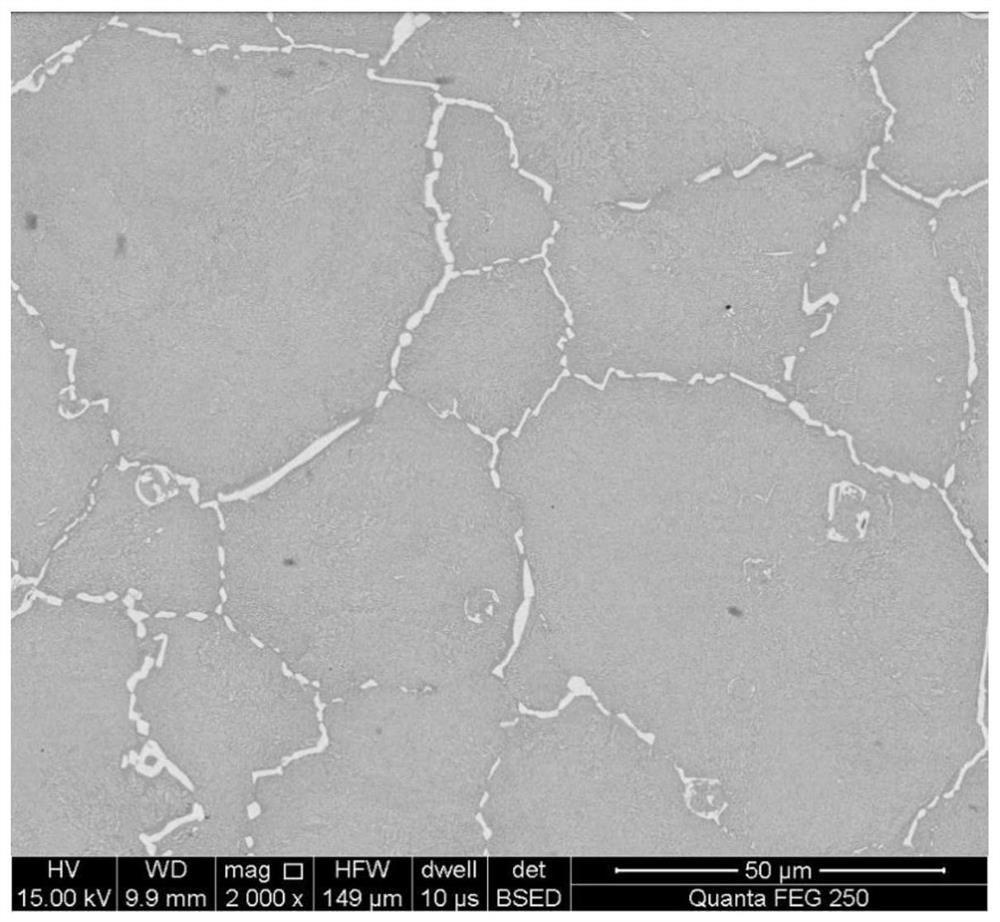

Embodiment 1

[0040] The mass fractions are: Co: 25%, Mo: 12%, W: 4%, TiC: 2%, Ti(C, N): 2%, the balance is Fe, and the powder is prepared. Mix the prepared raw material powder, 4wt% forming agent paraffin, and 0.5wt% carbon black, and place them in a planetary ball mill ball mill tank for wet ball milling. During the ball milling process, the ball milling medium is alcohol, the protective gas is nitrogen, and the ball-to-battery ratio is 5: 1. The speed is 260r / min, and the ball milling time is 48h. After the ball milling is completed, it is dried in a vacuum drying oven, dried and sieved to granulate, and the mixed powder is subjected to unidirectional molding under a pressure of 180 MPa to obtain a compact. The compact is placed in a vacuum sintering furnace for sintering, the final sintering temperature is 1340°C, the highest temperature stage is kept for 2 hours, and the sintered compact is obtained after cooling with the furnace. The sintered billet was preheated at 1120°C in a nitrog...

Embodiment 2

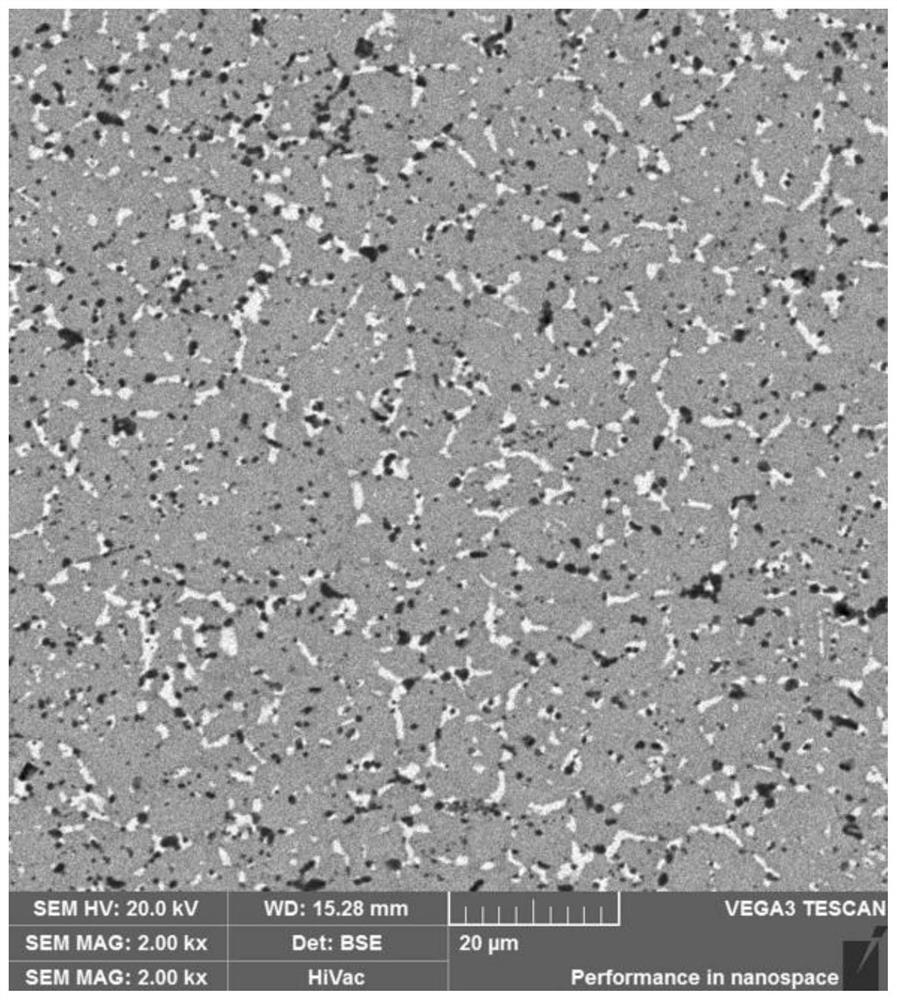

[0042] The mass fractions are: Co: 20%, Mo: 11%, W: 5%, TiN: 4%, Ti(C, N): 4%, the balance is Fe, and the powder is prepared. Mix the prepared raw material powder, 3wt% forming agent paraffin, and 0.6wt% carbon black, and place them in the ball mill tank of a planetary ball mill for wet ball milling. During the ball milling process, the milling medium is alcohol, the protective gas is nitrogen, and the ball-to-battery ratio is 6: 1. The rotating speed is 240r / min, and the ball milling time is 50h. After the ball milling is completed, it is dried in a vacuum drying box, dried and sieved to granulate, and the mixed powder is subjected to unidirectional molding under a pressure of 160 MPa to obtain a compact. The compact is placed in a vacuum sintering furnace for sintering, the final sintering temperature is 1370°C, the highest temperature stage is kept for 2 hours, and the sintered compact is obtained after cooling with the furnace. The sintered billet was preheated at 1130°C i...

Embodiment 3

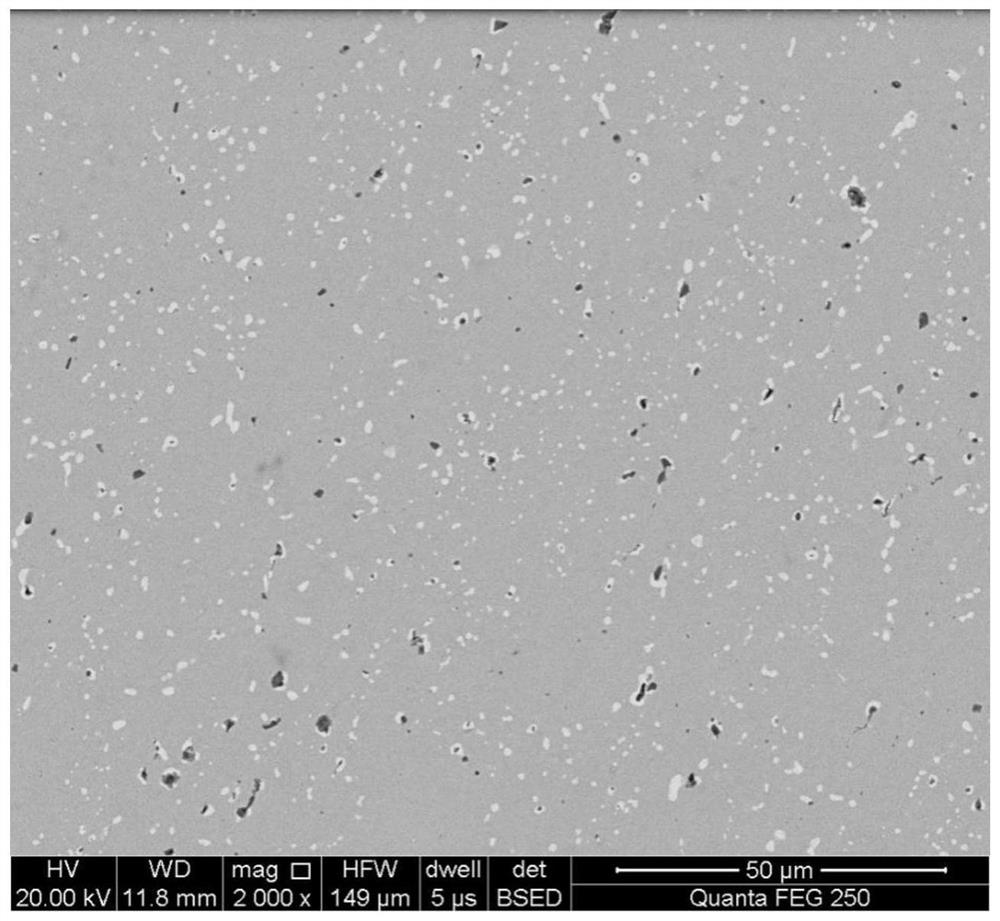

[0044] The mass fractions are: Co: 20%, Mo: 15%, W: 5%, NbC: 8%, the balance is Fe, and the powder is prepared. Mix the prepared raw material powder, 3wt% forming agent paraffin, and 0.6wt% carbon black, and place them in the ball mill tank of a planetary ball mill for wet ball milling. During the ball milling process, the milling medium is alcohol, the protective gas is nitrogen, and the ball-to-battery ratio is 6: 1. The speed is 220r / min, and the ball milling time is 60h. After the ball milling is completed, it is dried in a vacuum drying oven, dried and sieved to granulate, and the mixed powder is subjected to unidirectional molding under a pressure of 180 MPa to obtain a compact. The compact is placed in a vacuum sintering furnace for sintering, the final sintering temperature is 1340°C, the highest temperature stage is kept for 2 hours, and the sintered compact is obtained after cooling with the furnace. The sintered billet was preheated at 1130°C in a nitrogen-protected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com