Oil-resistant composite fiber warp-knitted flannelette processing technology

A composite fiber and processing technology, applied in the field of textile fabrics, can solve the problems of poor body feeling, poor oil resistance effect, easy to be contaminated with oil stains, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

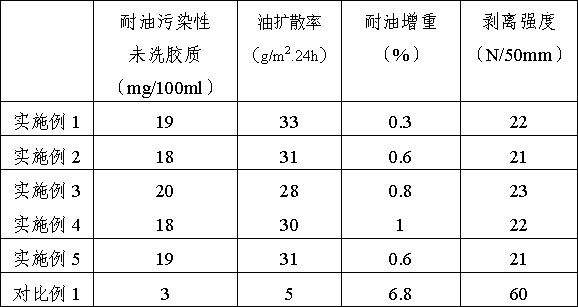

Examples

Embodiment 1

[0024] A kind of oil-resistant composite fiber warp-knitted flannelette processing technology, its processing technology comprises the following steps:

[0025] a, phthalonitrile and acrylonitrile in AlCl 3 Under catalysis, acrylonitrile replaces the hydrogen atom on phthalonitrile to obtain 1-acrylonitrile phthalonitrile solution;

[0026] b. Add deionized water and emulsifier into the reaction kettle, the weight ratio of deionized water to emulsifier is 250:3, start to stir and heat in water bath, when the emulsifier dissolves, raise the temperature to 78°C, use The pipette accurately adds K 2 S 2 o 8 solution and 1-acrylonitrile phthalonitrile, deionized water: K 2 S 2 o 8 Solution: The ratio of 1-acrylonitrile-phthalonitrile is 5:1:1. Rapidly raise the temperature to 88°C and maintain this temperature for 1.52h. Then, pour the emulsion into a beaker, add NaCl, and stir rapidly to break the emulsion , filtered with a Buchner funnel, the filtered polymer was washed wi...

Embodiment 2

[0031] A kind of oil-resistant composite fiber warp-knitted flannelette processing technology, its processing technology comprises the following steps:

[0032] a, phthalonitrile and acrylonitrile in AlCl 3 Under catalysis, acrylonitrile replaces the hydrogen atom on phthalonitrile to obtain 1-acrylonitrile phthalonitrile solution;

[0033] b. Add deionized water and emulsifier into the reaction kettle, the weight ratio of deionized water to emulsifier is 250:3, start to stir and heat in water bath, when the emulsifier dissolves, raise the temperature to 79°C, use The pipette accurately adds K 2 S 2 o 8 solution and 1-acrylonitrile phthalonitrile, deionized water: K 2 S 2 o 8 Solution: The ratio of 1-acrylonitrile-phthalonitrile is 5:1:1. Rapidly raise the temperature to 90°C and maintain this temperature for 1.5h. Then, pour the emulsion into a beaker, add NaCl, and stir rapidly to break the emulsion , filtered with a Buchner funnel, the filtered polymer was washed wit...

Embodiment 3

[0038] A kind of oil-resistant composite fiber warp-knitted flannelette processing technology, its processing technology comprises the following steps:

[0039] a, phthalonitrile and acrylonitrile in AlCl 3Under catalysis, acrylonitrile replaces the hydrogen atom on phthalonitrile to obtain 1-acrylonitrile phthalonitrile solution;

[0040] b. Add deionized water and emulsifier into the reaction kettle, the weight ratio of deionized water to emulsifier is 250:3, start to stir and heat in water bath, when the emulsifier dissolves, raise the temperature to 80°C, use The pipette accurately adds K 2 S 2 o 8 solution and 1-acrylonitrile phthalonitrile, deionized water: K 2 S 2 o 8 Solution: The ratio of 1-acrylonitrile-phthalonitrile is 5:1:1. Rapidly raise the temperature to 89°C and maintain this temperature for 1.46h. Then, pour the emulsion into a beaker, add NaCl, and stir rapidly to break the emulsion , filtered with a Buchner funnel, the filtered polymer was washed wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com