Composite combustion system with acid gas and fuel gas spray guns

A combustion system, acid gas technology, applied in the direction of gas fuel burner, combustion air/fuel supply, burner, etc., can solve the problem of large space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] It should be noted that the embodiments of the present invention and the features in the embodiments can be combined with each other if there is no conflict.

[0029] Hereinafter, the present invention will be described in detail with reference to the drawings and in conjunction with the embodiments.

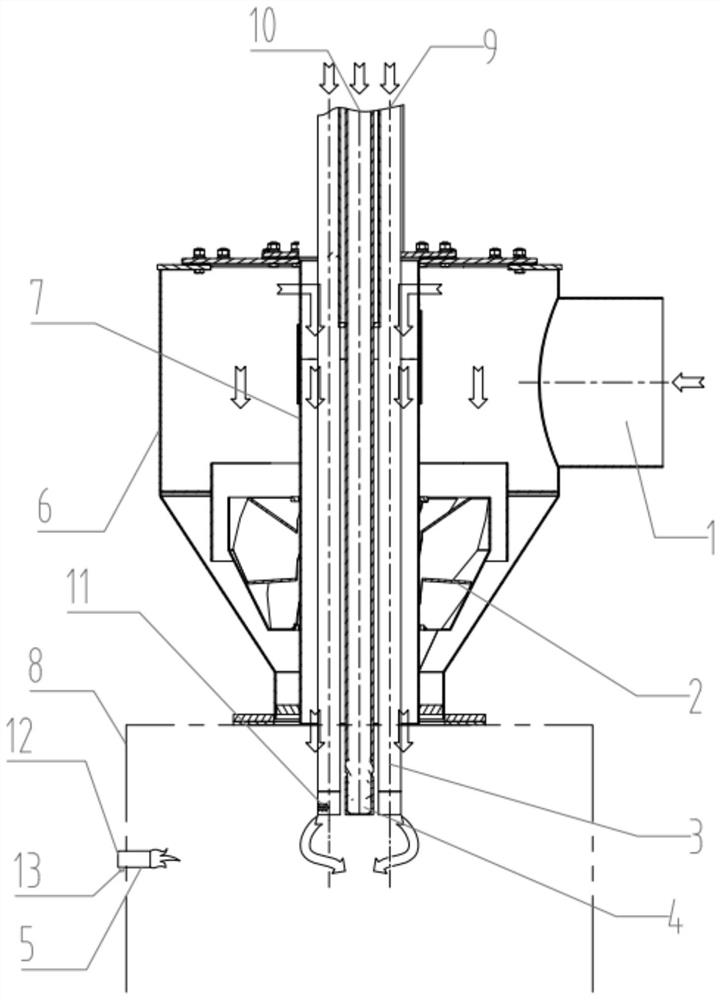

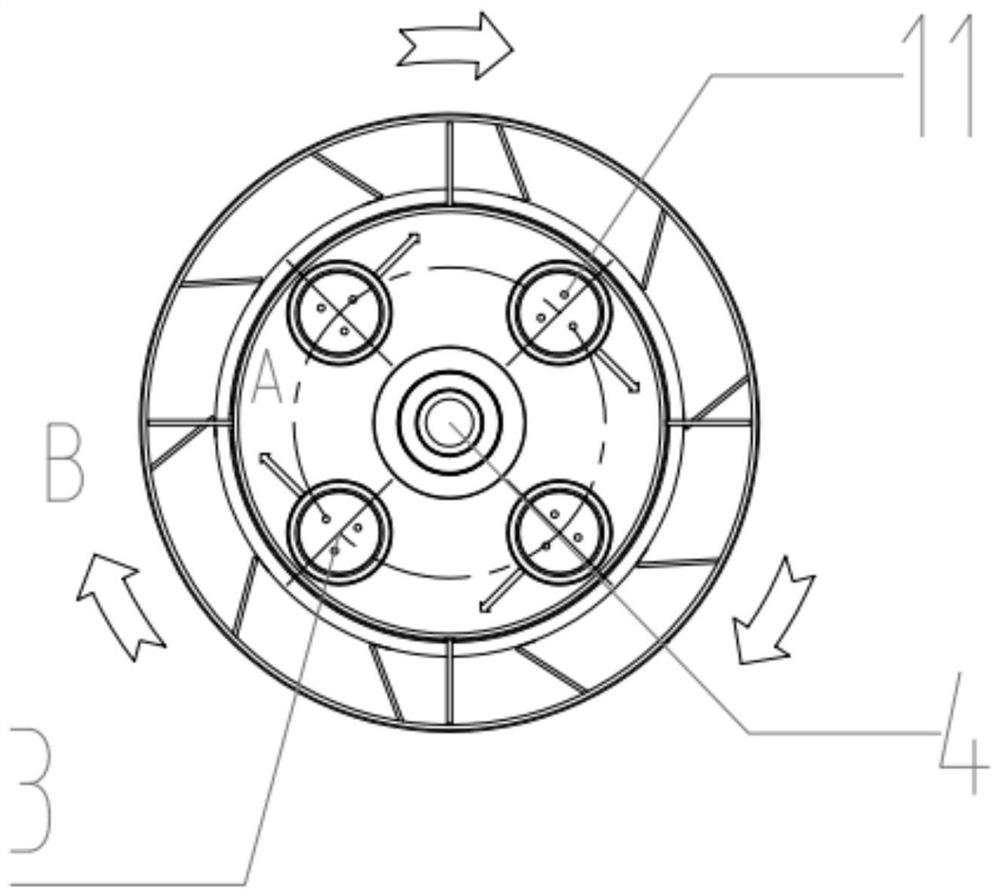

[0030] Such as Figure 1-Figure 2 As shown, a composite combustion system with acid gas and fuel gas spray guns includes a primary air inlet channel 7, a secondary air inlet channel 6, a number of fuel gas spray guns 3, an acid gas spray gun 4 and a swirl generator 2. The air spray guns 3 can be provided with three, four or five, depending on the requirements of the cracking furnace body 8. The primary air inlet channel 7 is vertically arranged in the secondary air inlet channel 6, and several fuels The gas spray gun 3 and the acid gas spray gun 4 are both arranged in the primary air inlet passage 7, the acid gas spray gun 4 is arranged at the central axis of the primary air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com