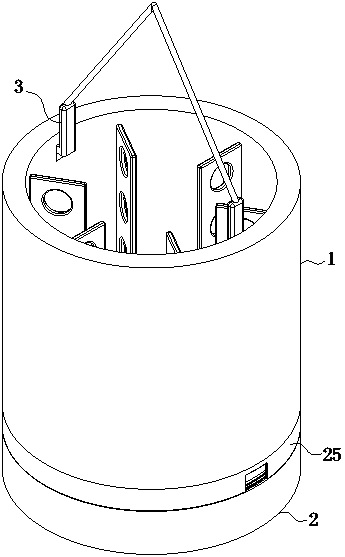

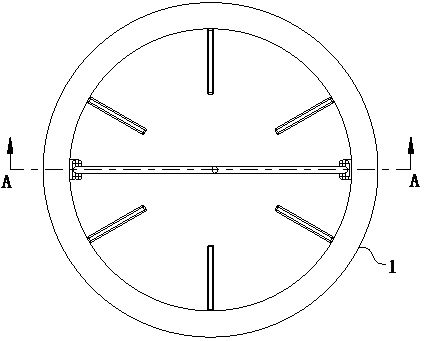

An electrode cylinder for a ferroalloy high-power DC electric furnace

An electrode cylinder and high-power technology, which is applied in the direction of electric furnace heating, furnace, electrical components, etc., can solve the problems of life-threatening, easy to injure the staff, cause fire and other problems, so as to ensure the health and safety of life and avoid the splashing of sparks out, improve the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

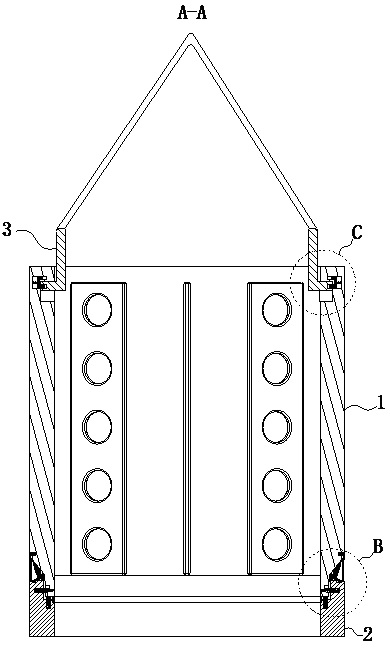

[0025] As an embodiment of the present invention, the electrode cartridge body 1 is provided with communication grooves correspondingly at the position of the second slider 13; the interior of the communication grooves is slidably connected with a communication block 32; the surface of the communication block 32 Both are provided with connecting holes connecting front and rear; the third spring 33 is firmly connected between the connecting block 32 and the bottom of the corresponding connecting groove; the inside of the electrode cartridge body 1 is provided with a connecting hole at the position of the connecting block 32; The electrode cartridge body 1 is provided with grooves at the positions of the two hooks 3; the insides of the two grooves are provided with fixing grooves near the upper surface of the grooves; the insides of the fixing grooves are slidingly connected with Fixed block 34; the fourth spring 35 is fixedly connected between the fixed block 34 and the groove b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com