Reinforced concrete sample and preparation method and application thereof

A reinforced concrete and concrete technology, applied in the preparation of test samples, measuring devices, instruments, etc., can solve the problems of long cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

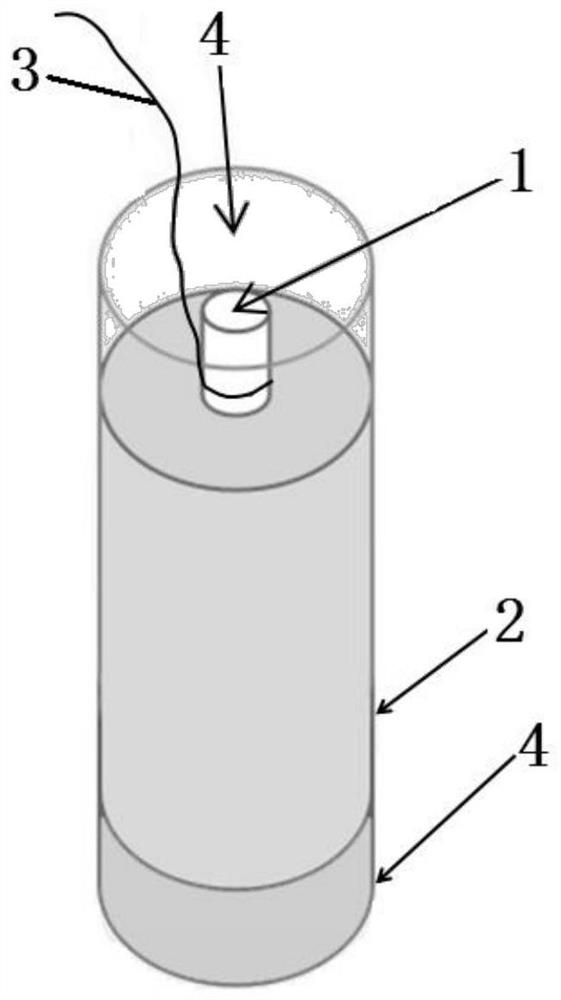

[0034] The present invention also provides the preparation method of the reinforced concrete sample described in above-mentioned technical scheme, comprises the following steps:

[0035] Grinding the stainless steel plate to obtain the polished stainless steel plate; fixing the steel rod to be corroded and the PVC pipe on the polished stainless steel plate to obtain a mold; the steel rod to be corroded is located at the center of the PVC pipe, and the to-be-corroded There is a gap between the corroded steel rod and the inner wall of the PVC pipe; the length of the steel rod to be corroded is greater than the length of the PVC pipe;

[0036] Applying silicone oil on the inner wall of the PVC pipe of the mold, pouring concrete into the gap between the steel rod to be corroded and the inner wall of the PVC pipe to obtain a grouting mold;

[0037] After the grouting mold is cured, it is removed from the mold, a copper wire is wound on the exposed part of the steel rod to be corrod...

Embodiment 1

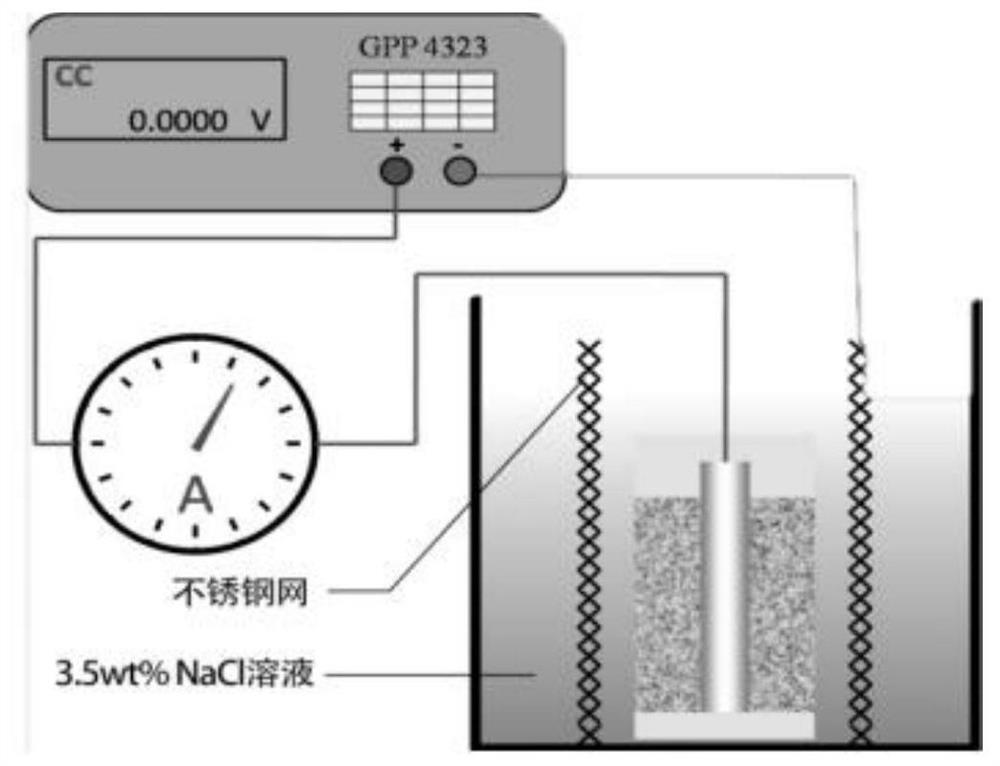

[0064] The size parameters are 5mm in diameter, 50mm in length, and the surface of the steel rod to be corroded is mechanically polished to a smooth surface, and the bottom of the PVC pipe is bonded to the stainless steel plate to ensure that the steel rod to be corroded is at the center of the bottom circle of the PVC pipe and evenly inside the PVC pipe. Apply a layer of silicone oil, and then pour the concrete with a water-cement ratio of 0.6 and a lime-sand ratio of 1:3 (the cement is ordinary C20 cement, and the sand is quartz sand with a fineness modulus of 1.7 to 2.2) that is fully mixed and uniform. Corrode the middle part of the steel rod and the inner wall of the PVC pipe, use a small rod to tamp the concrete in the mold, let it stand for 2 days and then take off the PVC pipe, tie the exposed part of the steel rod to be corroded with copper wire (the number of winding turns of the copper wire is 5 turns) , the bottom concrete part and the top exposed steel part are sea...

Embodiment 2

[0067] The size parameters are 5mm in diameter, 50mm in length, and the surface of the steel rod to be corroded is mechanically polished to a smooth surface, and the bottom of the PVC pipe is bonded to the stainless steel plate. Try to ensure that the steel rod to be corroded is at the center of the bottom circle of the PVC pipe and inside the PVC pipe. Apply a layer of silicone oil evenly, and then pour the concrete (the cement is ordinary C20 cement, and the sand is quartz sand with a fineness modulus of 1.7 to 2.2) with a water-cement ratio of 0.6 and a lime-sand ratio of 1:3. For the middle part between the steel rod to be corroded and the inner wall of the PVC pipe, use a small rod to tamp the concrete in the mold, let it stand for 2 days and then take off the PVC pipe, and bind the exposed part of the steel rod to be corroded with a copper wire (the number of winding turns of the copper wire is 5 turns) ), the bottom concrete part and the top exposed steel part are sealed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com