On-line optical measurement system and method for influence of rotary eccentricity on crystalline state of spin-coated film

An optical measurement system and centrifuge technology, which is applied in semiconductor/solid-state device testing/measurement, electrical components, circuits, etc., can solve the problem of lack of effective data in the study of film formation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

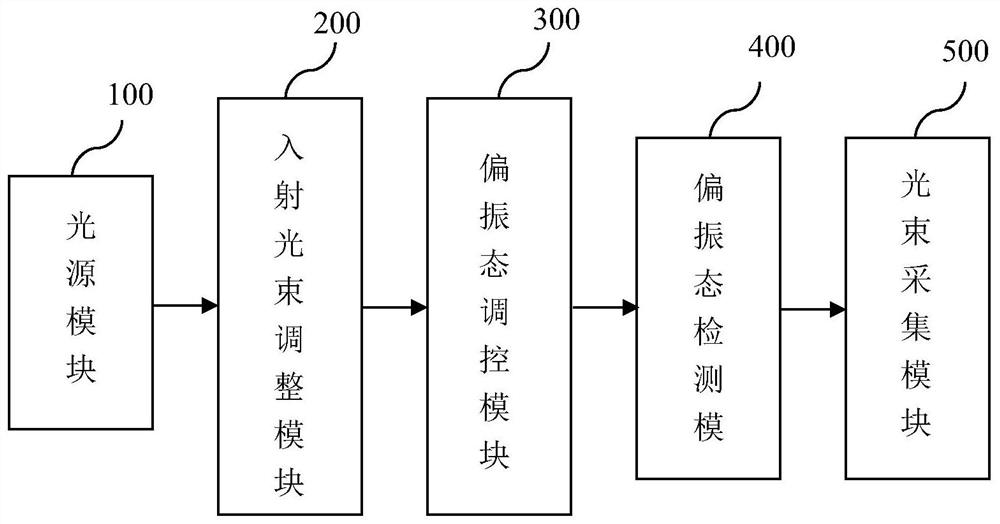

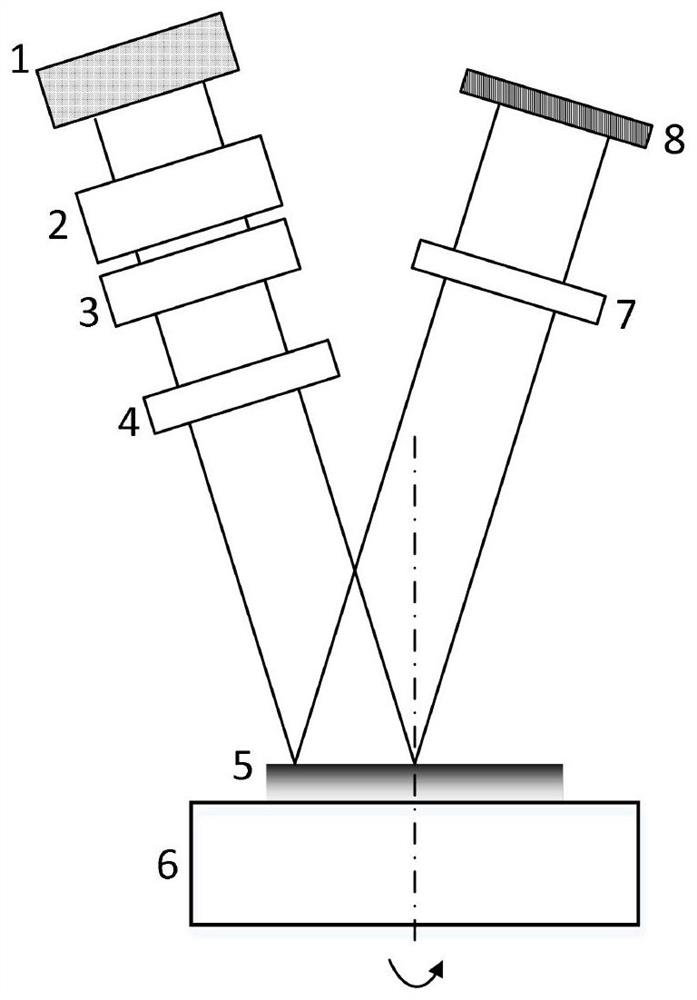

[0028] Such as figure 1 Shown is a schematic structural view of the online optical measurement system for the effect of the amount of rotation and centrifugation on the crystal state of the spin-coated thin film of the present invention. The system includes a light source module 100 , an incident light beam adjustment module 200 , a polarization state adjustment module 300 , a polarization state detection module 400 and a light beam collection module 500 . Wherein, the light source module 100 is used to output collimated monochromatic visible light; the incident beam adjustment module 200 is used to adjust the cross-sectional shape and size of the output beam of the light source module; the polarization state adjustment module 300 is used to adjust the incident beam Polarization state, forming linearly polarized light w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com