Shape-memory alloy and shape-memory alloy wire

A technology of memory alloy and alloy wire, which is applied in the field of shape memory alloy and shape memory alloy wire, and can solve problems such as lack of biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

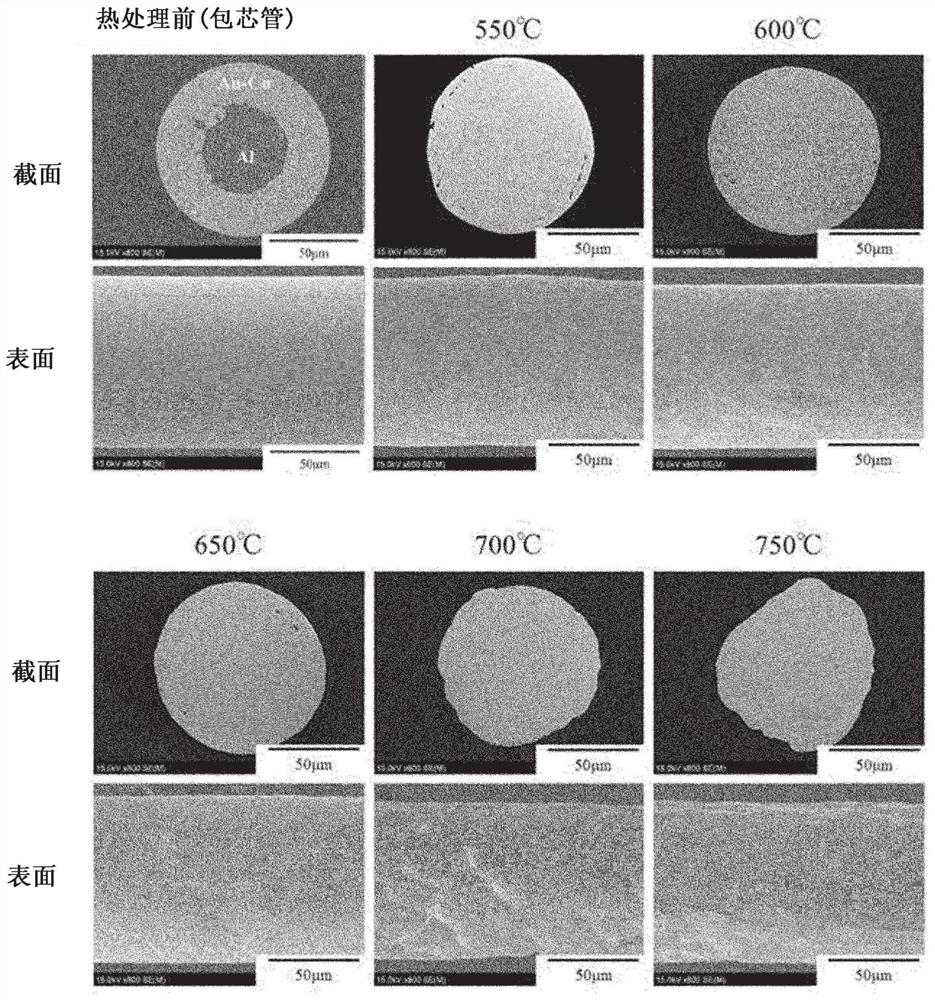

[0069] first embodiment : In this embodiment, a shape memory alloy wire rod made of an Au-25at%Cu-25at%Al alloy was produced. In addition, in the production of the shape memory alloy wire, it was examined whether the alloy wire can be produced while adjusting the heat treatment conditions and the like.

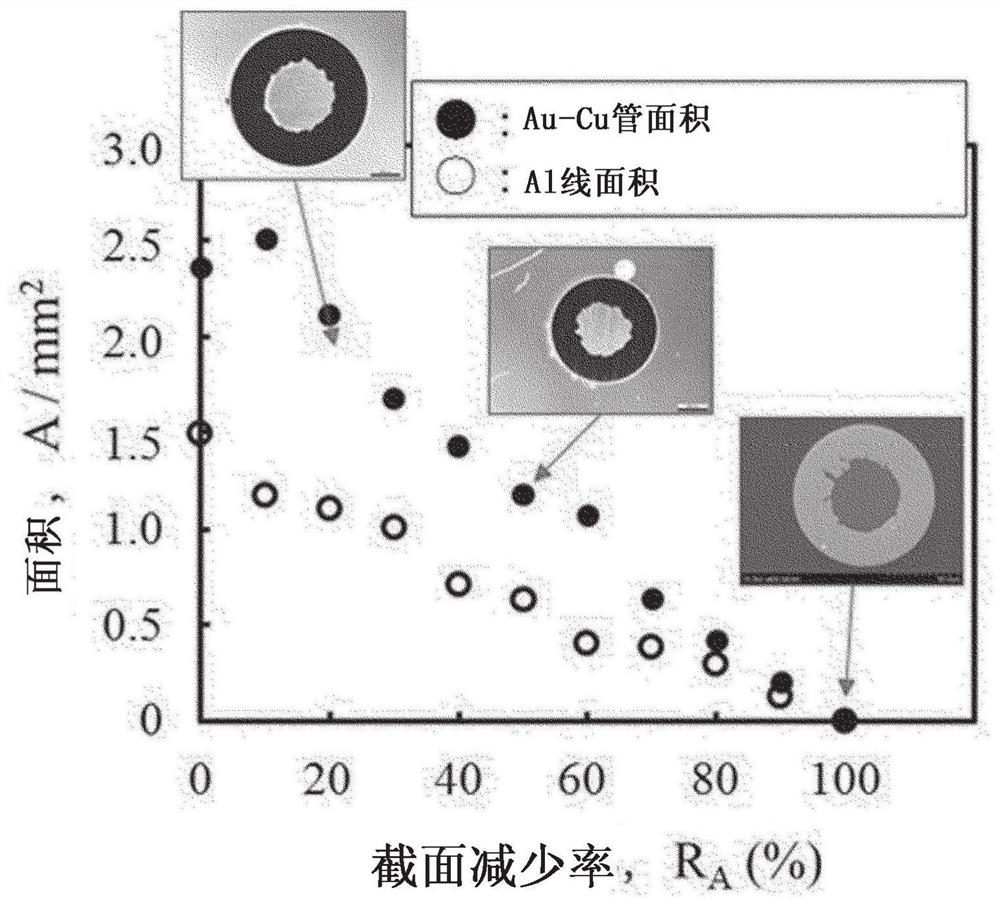

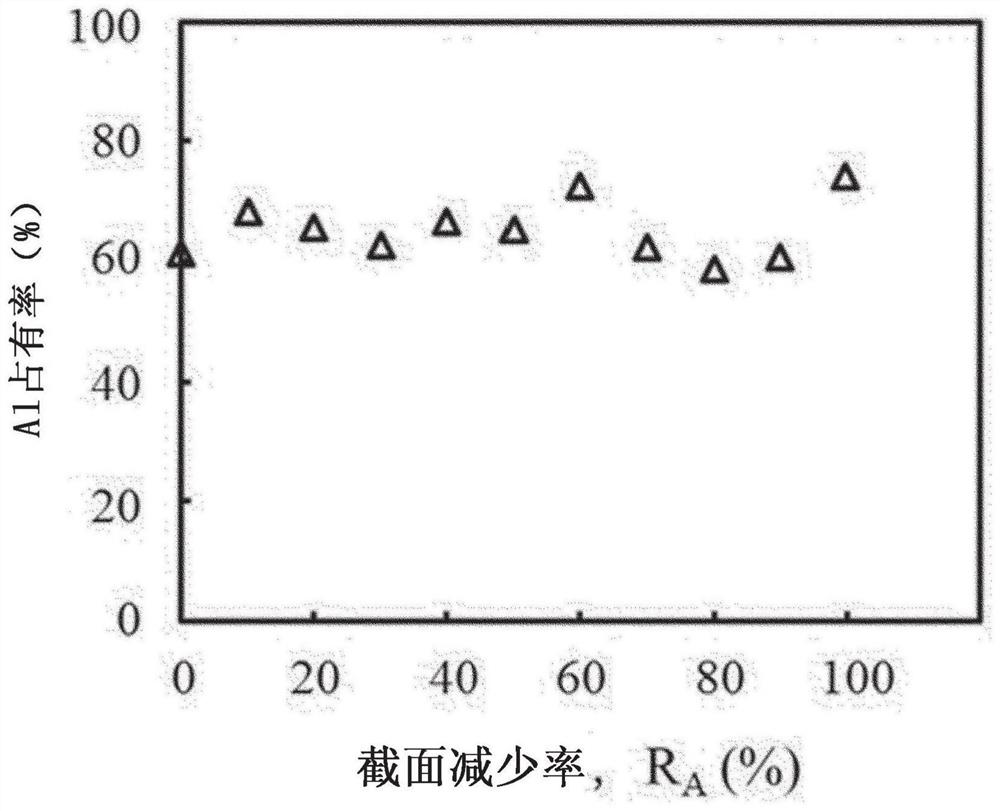

[0070] First, an Al wire with a wire diameter of 1.5 mm (purity 99.99%) was inserted into an Au-Cu alloy tube (outer diameter 3.53 mm, inner diameter 2.5 mm) of an Au-33.33 atomic % Cu alloy (Au-13.89 mass % Cu alloy), Extrusion processing was performed to produce a cored pipe with an outer diameter of 2.6 mm. According to the ratio of the cross-sectional area of the Au-Cu alloy tube to the cross-sectional area of the Al wire in the transverse section of the cored tube, the apparent composition is Au-25 atomic % Cu-25 atomic % Al alloy (Au-13.12 mass % Cu-5.57 mass % Al alloy).

[0071] The cored tube (Au-33.33 atomic % Cu alloy / Al tube: wire diameter: 2.6 mm) produced...

no. 2 approach

[0094] second embodiment : In this embodiment, shape memory alloy wires made of Au—Cu—Al alloys with various compositions were manufactured, and their respective characteristics were evaluated.

[0095] The manufacturing method of the alloy wire in this embodiment is the same as that of the first embodiment. Here, an Al wire rod (purity: 99.99%) with a wire diameter of 1.5 mm was inserted into an Au-Cu alloy tube (outer diameter: 3.53 mm, inner diameter: 2.5 mm) with adjusted Cu concentration, and extruded to produce a cored tube. Brushed processing. Here, too, the composition of the alloy wire is set in advance, and the ratio of the cross-sectional area of the Au—Cu alloy tube in the cored tube to the cross-sectional area of the Al wire is adjusted so that the apparent composition is consistent.

[0096] The wire drawing was repeated until the wire diameter became 100 μm so that the area reduction rate per pass became 10%. The temperature of the wire drawing process w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com