3D printing equipment and method for preparing medical porous tantalum metal implant material using the equipment

A technology of 3D printing and implanting materials, applied in medical science, additive processing, prosthesis, etc., can solve the problems of large material waste and low precision, and achieve the effect of saving manufacturing cost, improving applicability and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

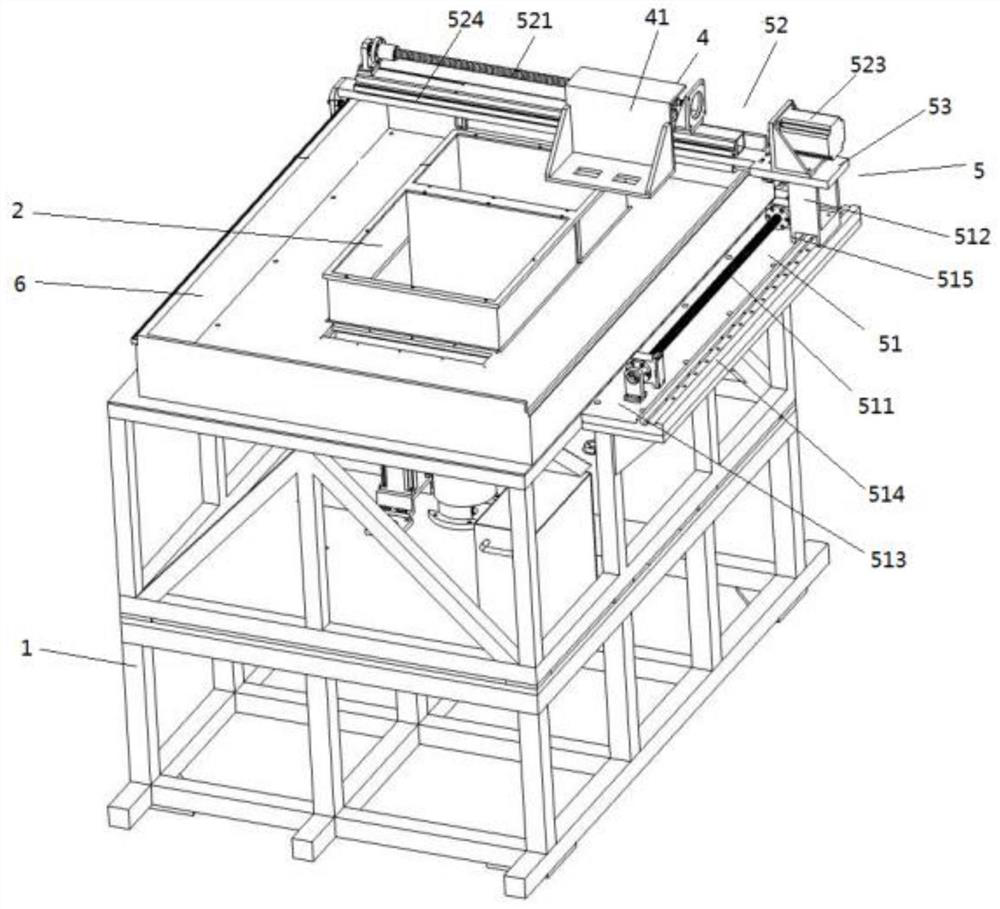

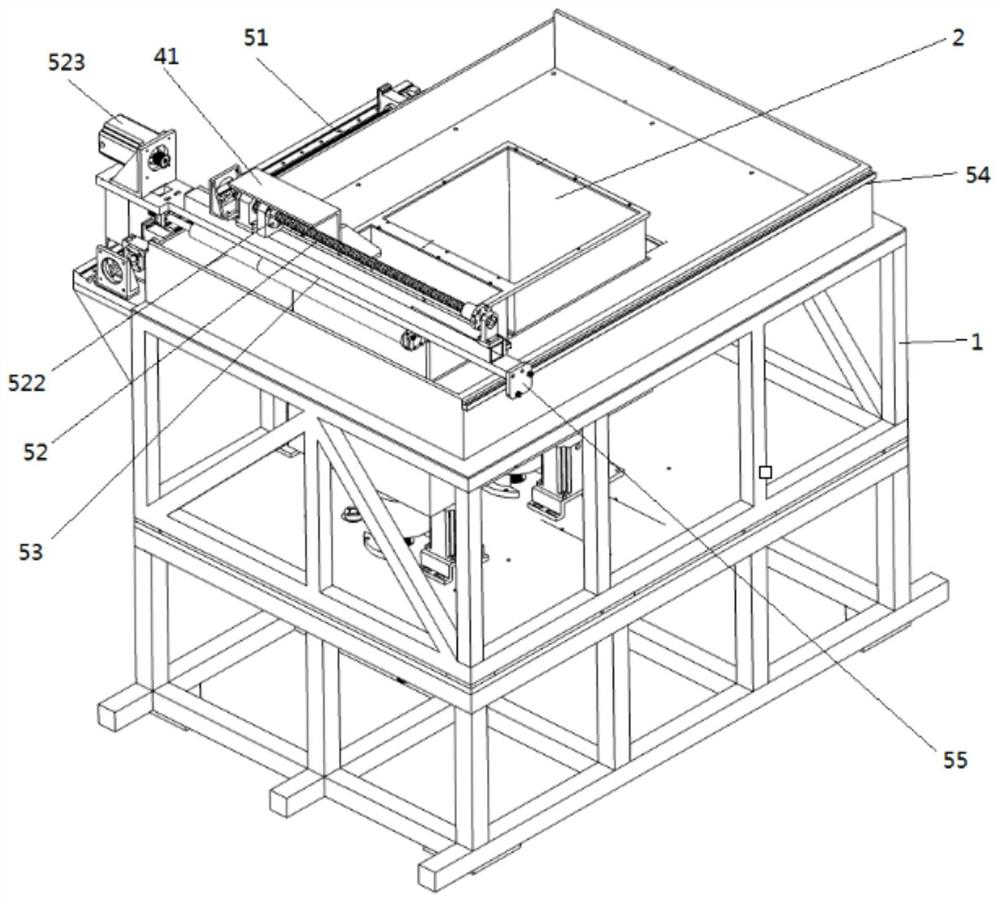

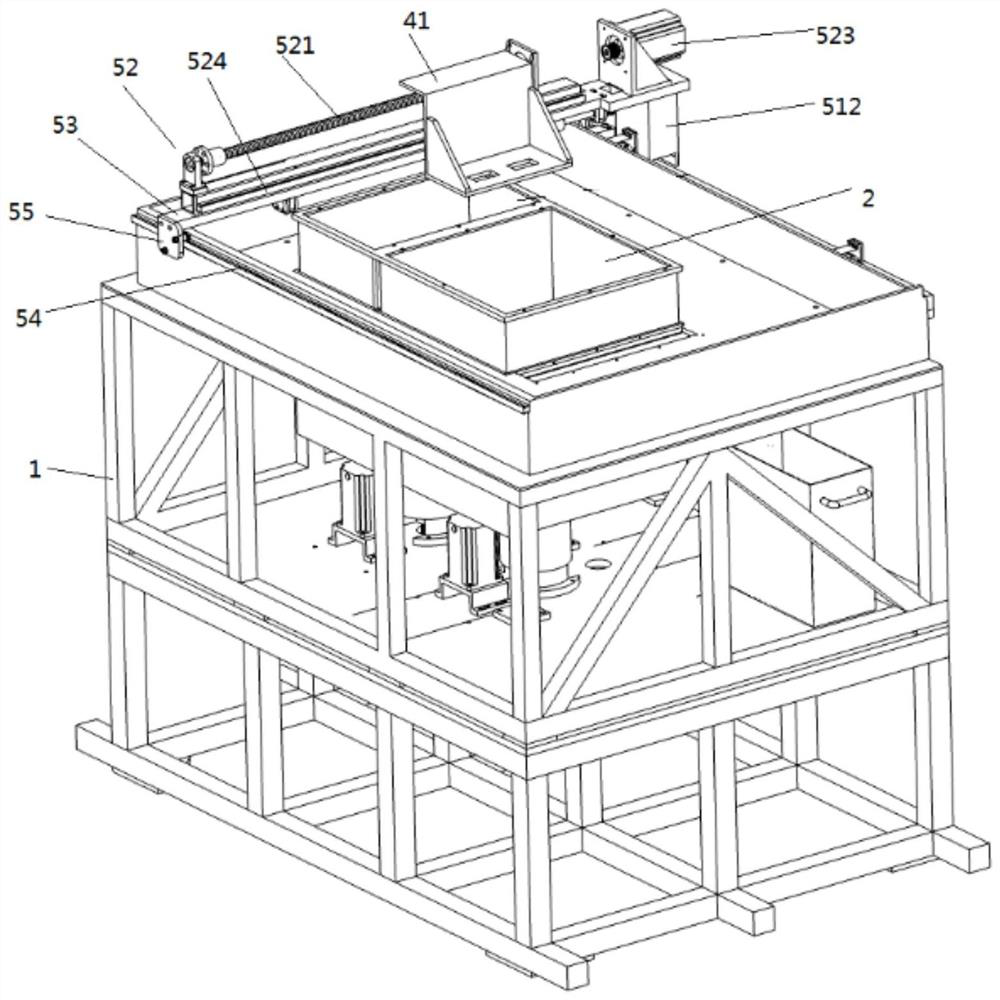

[0044] A 3D printing device, such as Figure 1-3 As shown, it includes a first support 1, a workbench 2, a lifting mechanism, a heating mechanism, a 3D printing unit 4 and a planar transmission mechanism 5. The workbench 2 is horizontally arranged above the first support 1, and the heating mechanism is set At the upper end of the workbench 2, the lifting mechanism is arranged in the first support 1 and is connected to the workbench 2 by transmission. The lifting mechanism drives the workbench 2 to move up and down, and also includes a recovery tank 6 , the recovery tank 6 is a cuboid with a hollow interior and an open upper end, the recovery tank 6 is horizontally arranged on the upper end of the first support 1, and a gap for the workbench 2 to pass is opened on the bottom wall thereof , the planar transmission mechanism 5 is arranged above the first bracket 1, and is connected to the 3D printing unit 4 arranged above the recovery tank 6, and the planar transmission mechanism...

Embodiment 2

[0074] A 3D printing device, using the same 3D printing device as in Example 1 to print and manufacture porous tantalum medical implant materials.

[0075] A preparation method for printing a medical porous tantalum metal implant material based on the 3D printing device described in any of the above embodiments, which mainly includes the following steps:

[0076] Step 1, ink making: configure 35 parts by weight of nano-metal tantalum powder, 3 parts by weight of polyurethane modified epoxy resin, 2 parts by weight of silicon dioxide, and ultrapure water of 60 parts by weight, for subsequent use;

[0077] Step 2. Stirring: Add ultrapure water in advance to the vacuum reactor and stir at 250 r / min at a low speed, then add the raw materials in step 1 at 200 r / min, and stir at 60°C for 3 hours. Get the ink containing metal tantalum and set aside.

[0078] Step 3. Import the STL file: Import the STL file of the designed porous tantalum three-dimensional model into the 3D printing ...

Embodiment 3

[0086] A 3D printing device, using the same 3D printing device as in Example 1 to print and manufacture porous tantalum medical implant materials.

[0087] A preparation method for printing a medical porous tantalum metal implant material based on the 3D printing device described in any of the above embodiments, which mainly includes the following steps:

[0088] Step 1, ink making: configure 42 parts by weight of nano-metal tantalum powder, 5 parts by weight of polyurethane modified epoxy resin, 3 parts by weight of silicon dioxide, and ultrapure water of 50 parts by weight, for subsequent use;

[0089] Step 2. Stirring: Add ultrapure water in advance to the vacuum reactor and stir at 300 r / min at a low speed, then add the raw materials in step 1 at 300 r / min, and stir at 65°C for 3 hours. Obtain the ink that contains metal tantalum, standby;

[0090] Step 3. Import the STL file: Import the STL file of the designed porous tantalum three-dimensional model into the 3D printing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com