A stainless steel surface polishing process

A surface polishing, stainless steel technology, applied in surface polishing machine tools, grinding/polishing equipment, grinding/polishing safety devices, etc. The effect of reducing the possibility of injury and improving the reuse rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

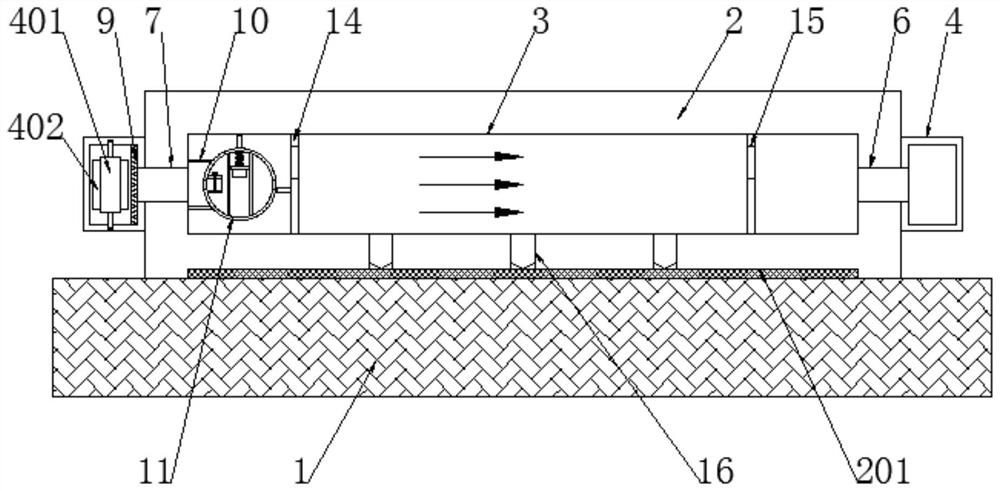

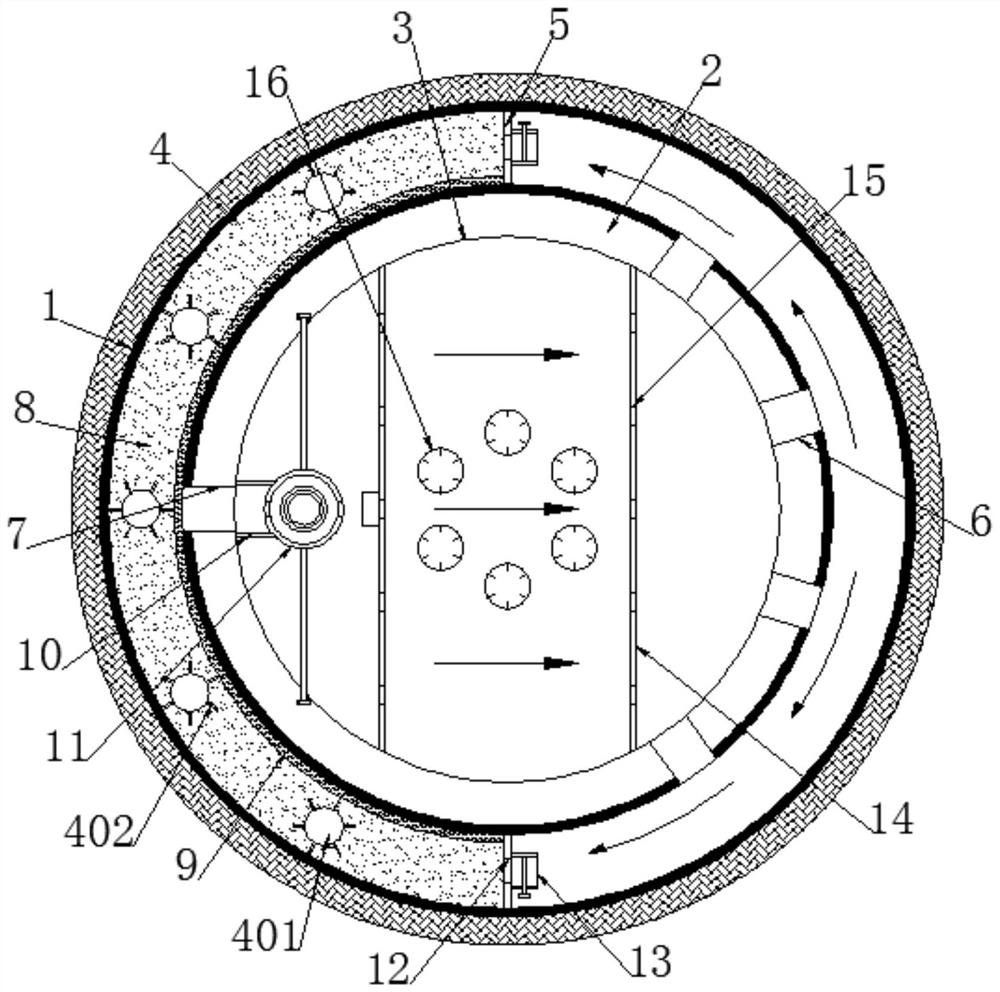

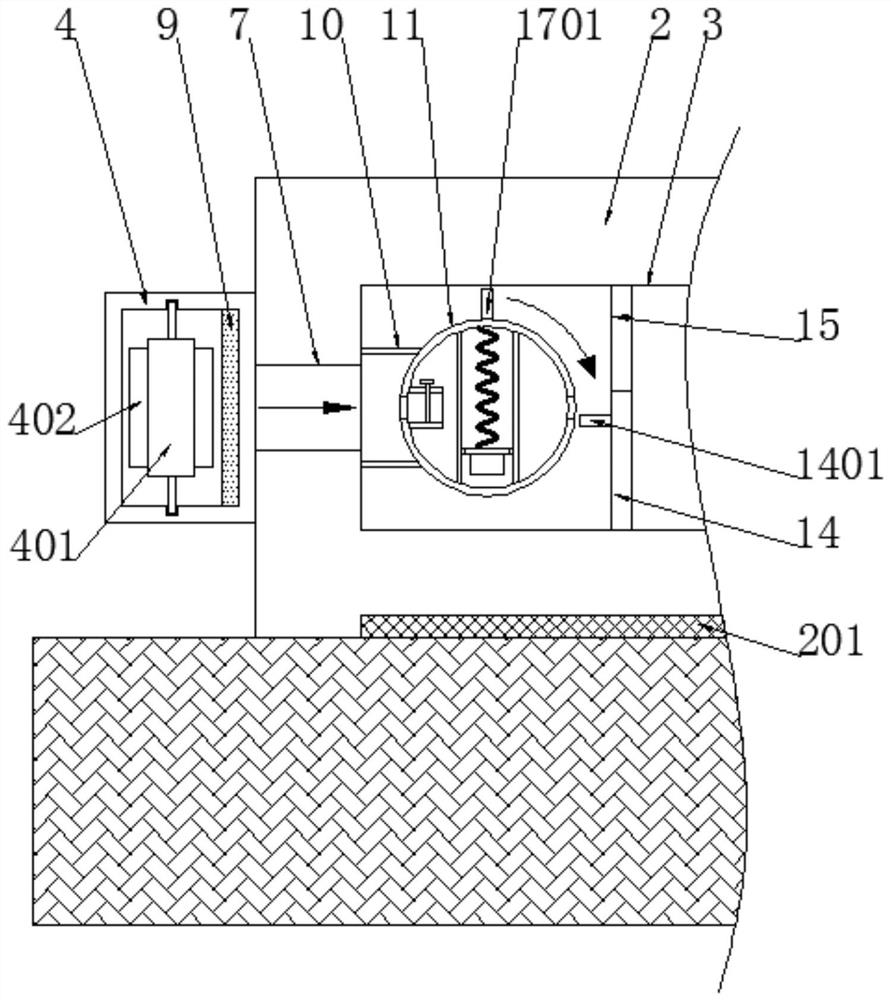

Image

Examples

Embodiment 1

[0045] A stainless steel surface polishing process is characterized in that: comprising the following steps:

[0046] S1. Place the stainless steel plate to be polished on the workbench and fix it, and use a grinding wheel to roughly grind the stainless steel surface;

[0047] S2. Install the negative pressure cloth wheel on the polishing machine, and sprinkle reduced iron powder on the surface of the rough-ground stainless steel plate. The area of the reduced iron powder is roughly the same as that of the negative pressure cloth wheel;

[0048] S3. Immediately use the negative pressure cloth wheel to polish the stainless steel plate covered with the reducing iron powder area, and complete the fine polishing of the stainless steel plate;

[0049] S4. After the fine polishing is completed, evenly cover the surface of the stainless steel plate with a polishing solution composed of red powder, water and nitric acid at a ratio of 1:2:8, polish the stainless steel plate into a mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com