Self-suction semi-permeable membrane drainage network and implementation method thereof

An implementation method, semi-permeable membrane technology, applied in chemical instruments and methods, water/sludge/sewage treatment, sludge treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

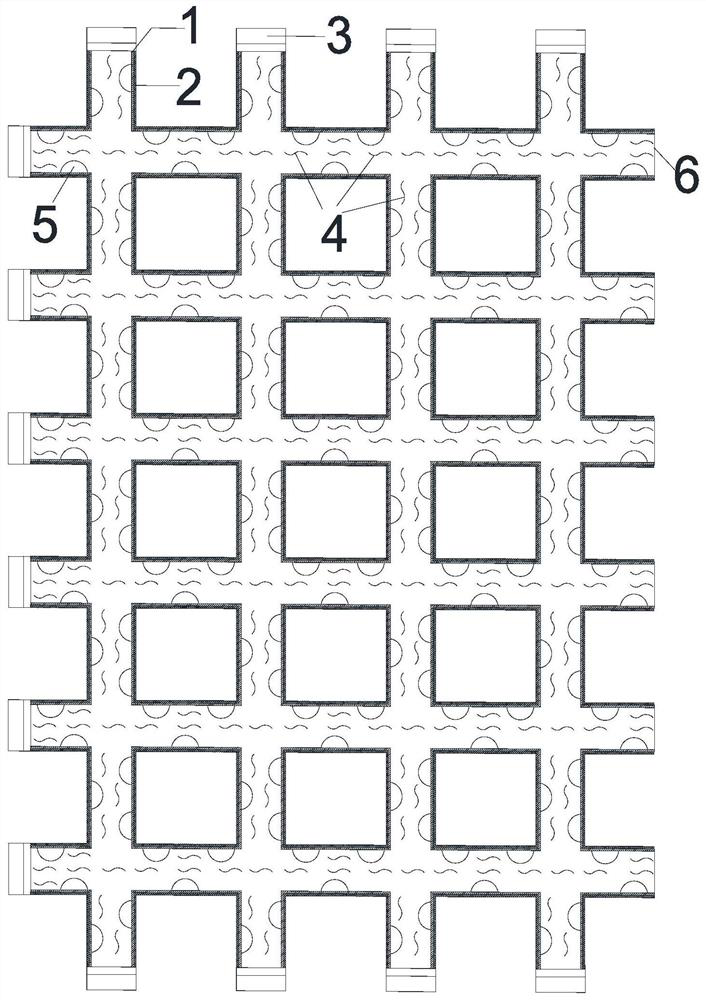

[0035] This embodiment provides a method for implementing a self-priming semi-permeable membrane drainage network, including the following steps:

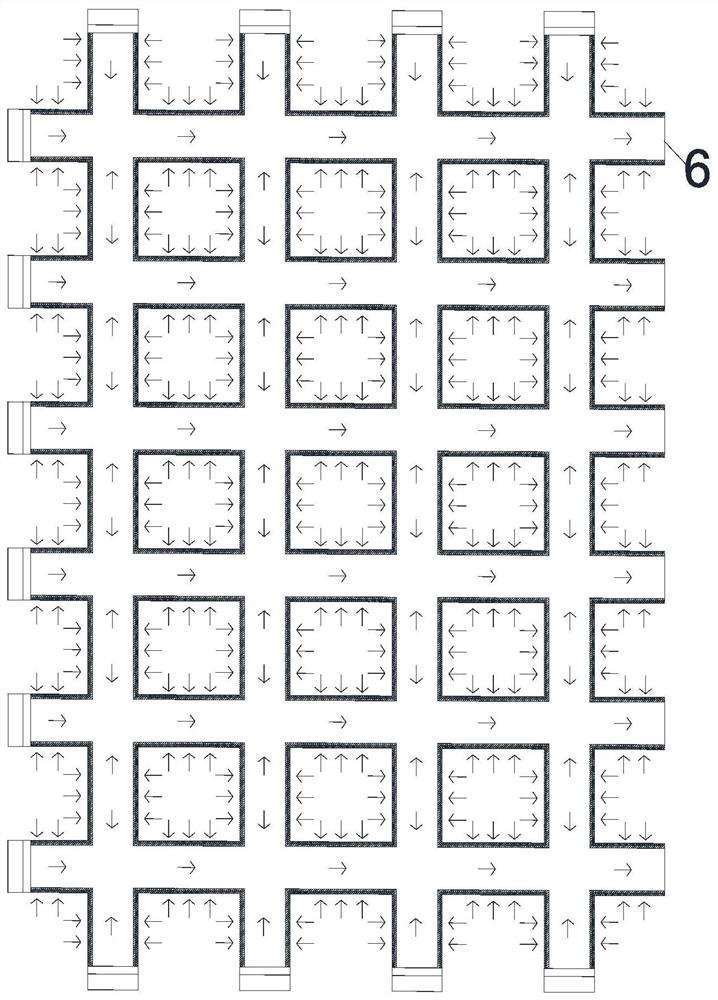

[0036] Step 1: Transport the solidified soil with high water content to the embankment filling place, fill half of the required height of the embankment, and then lay a self-priming semi-permeable membrane drainage network on the half-filled embankment 9 . Such as Figure 4 As shown, the top surface of the embankment 9 filled with half the height has a certain inclination, the liquid injection port 6 of the drainage net is located on the higher side, and the length of the PVC pipe 7 arranged laterally is greater than the width of the embankment 9, so The liquid injection port 6 exceeds the side of the embankment 9. In this embodiment, the inclination is 5-10°.

[0037] Step 2: Pour sulfurous acid pulp waste liquid 4 into the PVC pipe 7 of the drainage network through the liquid injection port 6 until the sulfurous acid pulp waste...

Embodiment 2

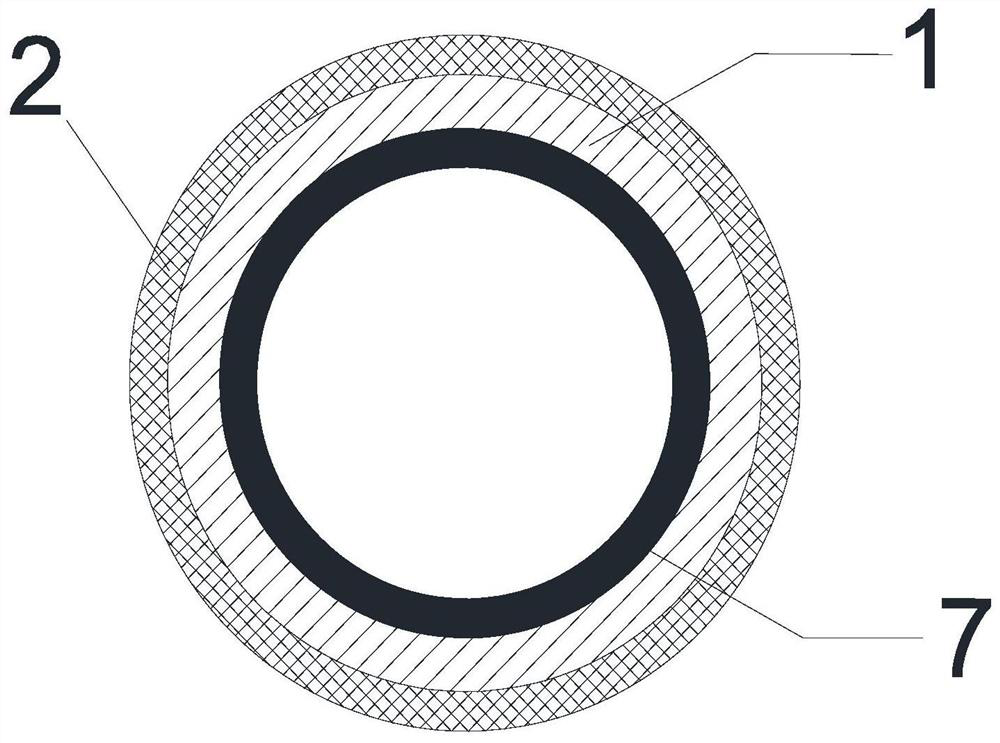

[0042] Step 1. Transport the solidified soil with high moisture content to the embankment filling place, fill half of the height first, and make a self-priming semi-permeable membrane drainage network. The length of the horizontal PVC pipe 7 of the self-priming semi-permeable membrane drainage network depends on the width of the embankment, and it is greater than the embankment 9 width 2m, and the length of the longitudinal PVC pipe 7 is 14m, and the diameter of the PVC pipe 7 is 5cm. On the wall, an electric drill is used to displace and open permeation holes 5 with a diameter of 3 cm, and the interval between the permeation holes 5 is 5 cm. The outside of the PVC pipe 7 is wrapped with a semi-permeable membrane 1 made of polyvinyl alcohol, and the outside of the semi-permeable membrane 1 is wrapped and fixed with barbed wire or a synthetic resin net.

[0043]Step 2. Laying a self-priming semi-permeable membrane drainage network on the embankment 9 filled with half the height...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com