Anti-static ceramic tile with nano-structure on surface, and preparation method thereof

A technology of nano-structure and ceramic tiles, applied in the field of industrial ceramics, can solve the problems of high cost, increase of production process and cost, and technical difficulty of production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

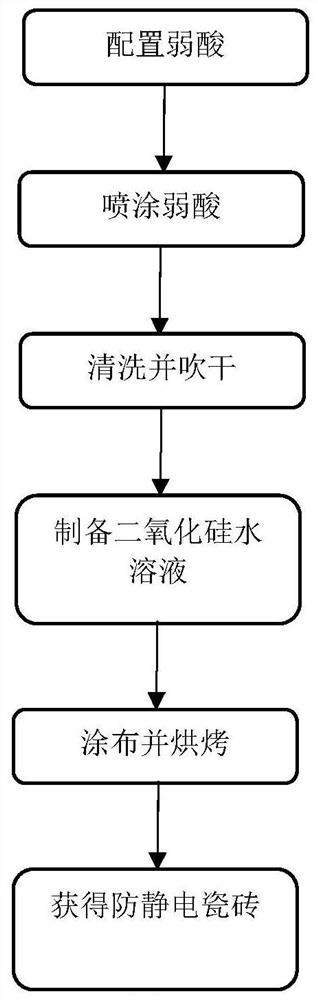

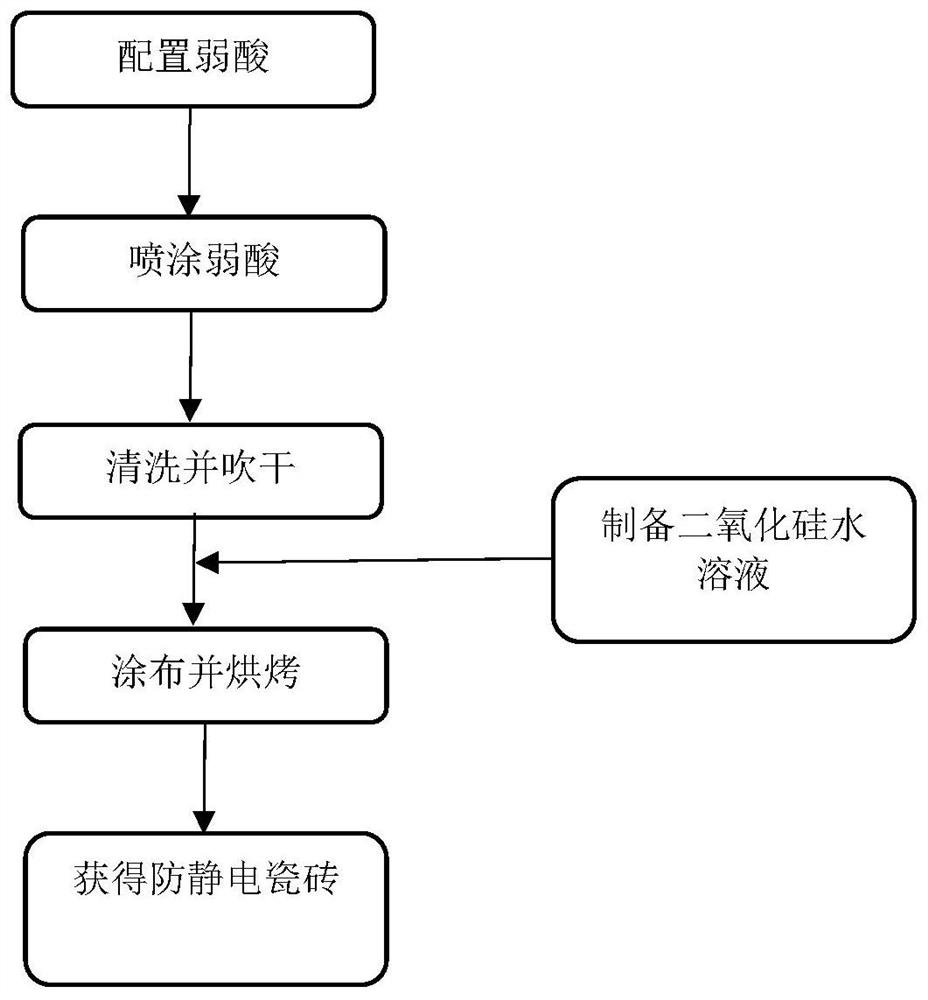

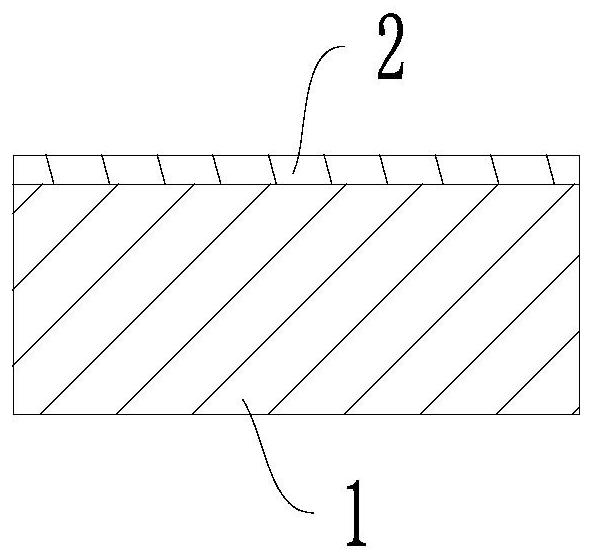

[0034] Embodiment 1 is an antistatic ceramic tile with a nanostructure on the surface and a preparation method disclosed by the present invention, the contents are as follows

[0035] 1) preferably select organic citric acid with a solubility of 5% to modify the microstructure of the ceramic tile 1 surface;

[0036] 2) The spraying method of the weak acid adopts an air pressure of 0.7MPa, the diameter of the nozzle is preferably 0.5mm, and the weak acid is sprayed on the surface of the ceramic tile 1, and the modification time of 120 seconds is preferably selected, and the roughness Ra of the formed microstructure is 0.15 μm;

[0037] 3) Rinse the surface of ceramic tile 1 with clean water, and dry the surface with natural wind until no obvious liquid water is visible to the naked eye;

[0038] 4) Coating the doped nano-silica aqueous solution on the surface of the modified ceramic tile 1 with a cotton cloth in a 100% wet and saturated state, the coating speed is 160mm / s, and ...

Embodiment 2

[0043] Embodiment 2 is an antistatic ceramic tile with a nanostructure on the surface and a preparation method disclosed by the present invention, the contents are as follows

[0044] 1) According to the selection plan of weak acid, organic citric acid with a solubility of 10% is preferably selected to modify the microstructure of the surface of the ceramic tile 1;

[0045] 2) The weak acid spraying method adopts an air pressure of 0.6-0.8 MPa, the nozzle diameter is preferably 0.6mm, and the weak acid is sprayed on the surface of the ceramic tile 1, and the modification time of 90 seconds is preferably selected, and the roughness Ra of the formed microstructure is 0.25 μm;

[0046] 3) Rinse the surface of ceramic tile 1 with clean water, and dry the surface with natural wind, so that no obvious liquid water can be seen with the naked eye;

[0047] 4) Coating the doped nano-silica aqueous solution on the surface of the modified ceramic tile 1 with cotton cloth in a 100% wet an...

Embodiment 3

[0052] Embodiment 3 is an antistatic ceramic tile with a nanostructure on the surface and a preparation method disclosed by the present invention, the contents are as follows

[0053] 1) preferably select organic citric acid with a solubility of 15% to modify the microstructure of the ceramic tile 1 surface;

[0054] 2) The weak acid spraying method adopts an air pressure of 0.8MPa, the nozzle diameter is preferably 1.0mm, and the weak acid is sprayed on the surface of the ceramic tile 1, preferably with a modification time of 120 seconds, and the roughness Ra of the formed microstructure is 0.4 μm;

[0055] 3) Rinse the surface of ceramic tile 1 with clean water, and dry the surface with natural wind until no obvious liquid water is visible to the naked eye;

[0056] 4) Coating the doped nano-silica aqueous solution on the surface of the modified ceramic tile 1 with a cotton cloth under a 100% wet saturation state, the coating speed is 120mm / s, and the preferred option three ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com