Calibration method, device and application of structured light system based on red and blue orthogonal stripes

A technology of structured light system and calibration method, which is applied in the field of structured light system calibration based on red and blue orthogonal stripes, can solve the problems of insufficient calibration accuracy, influence of calibration results, and inflexible operation, and achieve universality and high calibration speed. Fast, the effect of improving the calibration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

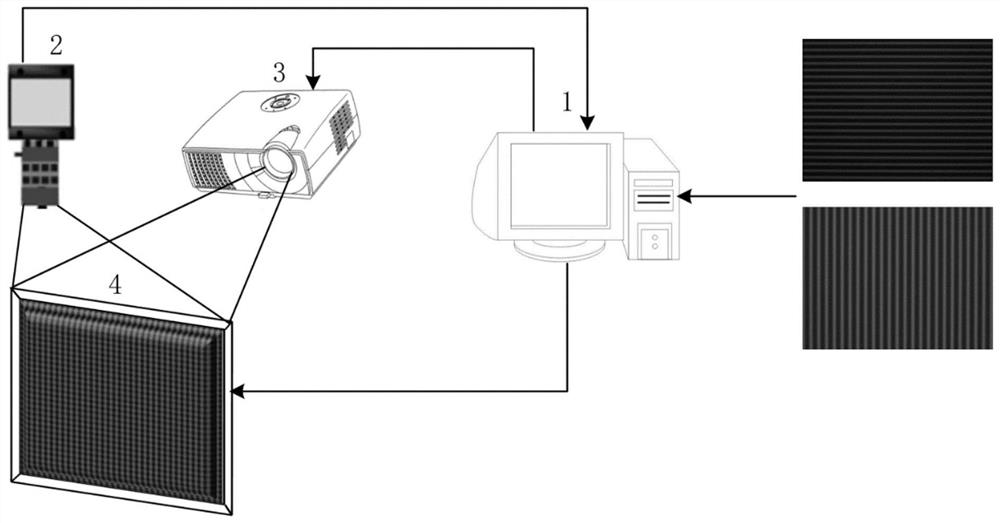

[0081] In this embodiment, the computer 1, the color CCD camera 2, the projector 3, the LCD display screen 4 and the holographic projection film are all commercial products. The camera 2 adopts the ECO424CVGE camera of German SVS-VISTEK company, and the physical resolution is 656×492. In addition, a zoom lens with a focus range of 12-36mm produced by Computar company is selected. The camera 2 is connected to the computer 1 through the gigabit network interface. connected. The projector 3 is a CP270 commercial projector 3 of BenQ Company, with a physical resolution of 1024×768, and is connected to the computer 1 through a VGA interface. The LCD display 4 adopts the LP097QX2 display screen of LG Company, with a physical resolution of 2048×1536, a size of 9.7 inches, and a pixel pitch of 0.096mm×0.096mm. It is connected to the computer 1 through an HDMI interface.

[0082] The red and blue orthogonal fringe image is coded by Matlab software. According to the size of the measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com