Anti-oxidative stress oral composite resin taking MitoQ nanoparticles as filler and preparation method of anti-oxidative stress oral composite resin

An anti-oxidative stress, nanoparticle technology, applied in dental preparations, pharmaceutical formulations, medical science and other directions, can solve the problems of oral tissue oxidative stress damage, polymerization heat generation and incomplete polymerization, polymerization shrinkage and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

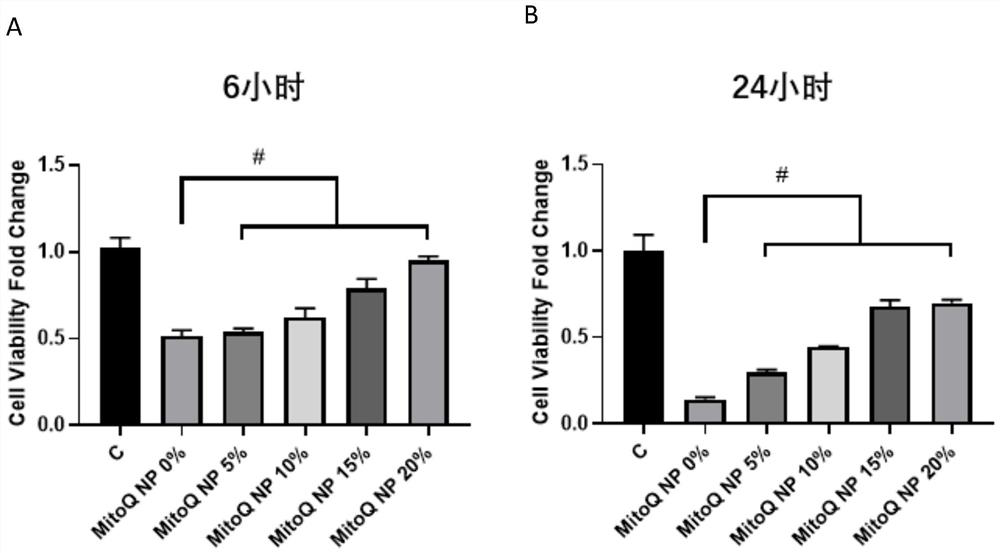

Image

Examples

Embodiment 1

[0034] Example 1 Preparation method of anti-oxidative stress oral cavity composite resin with MitoQ nanoparticles as filler

[0035] Step 1. Construct MitoQ nanoparticles:

[0036] (1) Hyaluronic acid is added to ultrapure water to prepare a concentration of 3mg / mL, and stirred until completely dissolved;

[0037] (2) Dissolve MitoQ in DMSO under ultrasonic treatment to adjust the concentration to 24mg / mL;

[0038] (3) Add the MitoQ / DMSO solution dropwise to the hyaluronic acid solution to form a MitoQ / HA solution with a concentration of 0.18mg / mL;

[0039] (4) Dialyze with a dialysis bag with a molecular weight cut-off of 8000Da for 2 hours to remove a small amount of DMSO, and sterilize at 121°C to obtain Mito Q / HA nanoparticles.

[0040] Step 2. Disperse and mix Mito Q / HA nanoparticles and inorganic glass powder under ultrasound. The glass powder is divided into 0.4um and 2um diameters. The configuration is that 0.4um glass powder accounts for 65wt% of the total weight, a...

Embodiment 2

[0043] Example 2 Preparation method of anti-oxidative stress oral cavity composite resin with MitoQ nanoparticles as filler

[0044] The difference from Example 1 is that the specific gravity of 2um glass powder, 0.4um glass powder and MitoQ NP is different. Select 0.4um glass powder to account for 60wt% of the total weight, 2um glass powder to account for 15wt% of the total weight, and MitoQ NP to account for 60% of the total weight 10 wt%.

Embodiment 3

[0045] Example 3 Preparation method of anti-oxidative stress oral cavity composite resin with MitoQ nanoparticles as filler

[0046] The difference from Example 1 is that the specific gravity of 2um glass powder, 0.4um glass powder and MitoQ NP is different. Select 0.4um glass powder to account for 55wt% of the total weight, 2um glass powder to account for 15wt% of the total weight, and MitoQ NP to account for 50% of the total weight. 15 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com