Modified adsorbent, refined grease and preparation method thereof

A technology for refining oil and adsorbent, applied in the field of refined oil and its preparation, modified adsorbent, and can solve problems such as poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

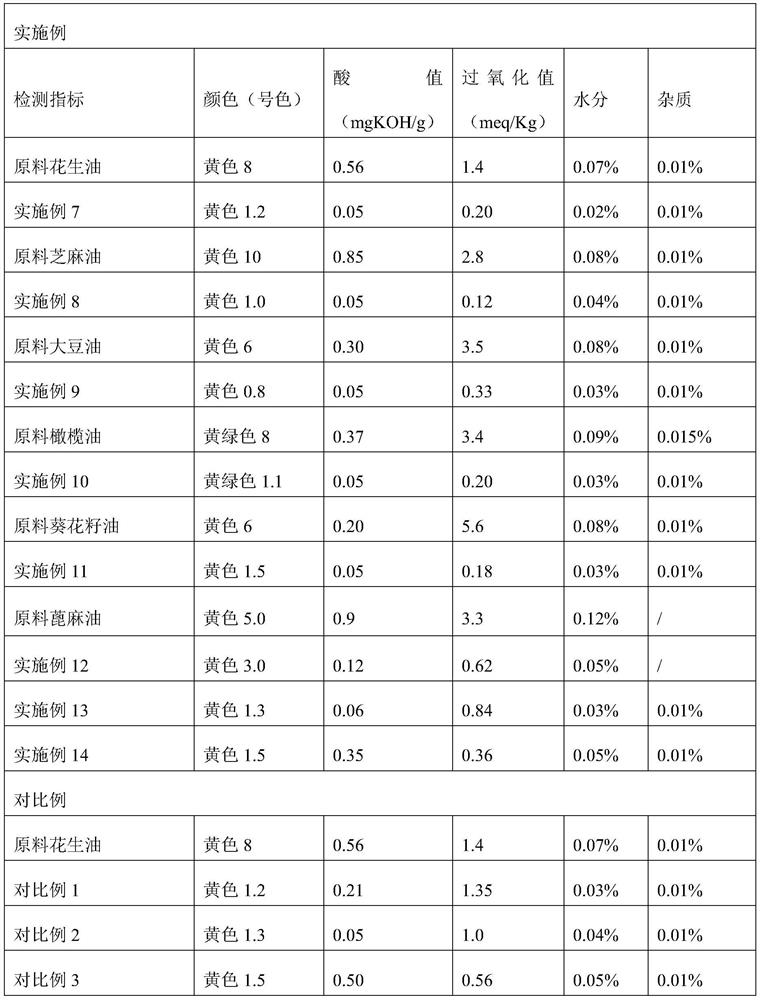

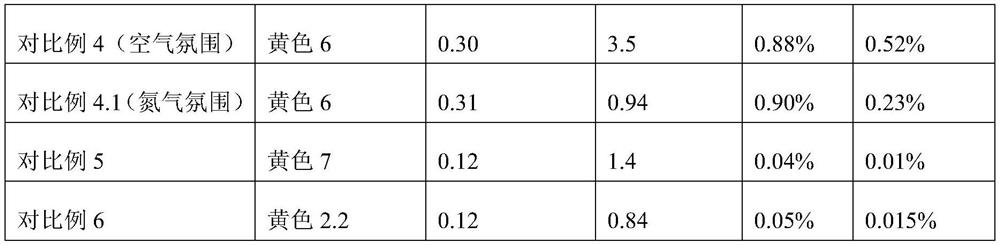

Examples

Embodiment 1

[0072] (1) Preparation of layered double metal hydroxides

[0073] In a 2L beaker, add 1.0mol magnesium hydroxide and 1.0mol aluminum hydroxide respectively, then add 500mL water, stir to mix the magnesium hydroxide and aluminum hydroxide evenly to obtain a suspension; mix 1.0mol sodium bicarbonate and Add 200mL of water into a 500mL beaker, stir to dissolve completely, and obtain a sodium bicarbonate solution; then add the sodium bicarbonate solution to the above suspension, stir for 30 minutes to mix evenly, and obtain a mixed solution;

[0074] Slowly raise the temperature of the above mixture to 80-90°C, control the heating rate at 0.5-1.0°C / min, and react at 80-90°C for 3 hours, then cool to room temperature, keep stirring for 3 hours, and then slowly heat up to 60-70°C °C, the heating rate is controlled at 1.0-2.0 °C / min. The layered double metal hydroxide was obtained. After drying, the layered double metal hydroxide had a mass of 165 g. A suspension with a mass concen...

Embodiment 2

[0078] (1) Preparation of layered double metal hydroxides

[0079] In a 2L beaker, add 1.0mol magnesium hydroxide and 1.0mol calcium hydroxide respectively, then add 500mL water, stir to mix the magnesium hydroxide and aluminum hydroxide evenly to obtain a suspension; mix 2.4mol sodium sulfate and 500mL Add water into a 1000mL beaker, stir to dissolve completely, and obtain a sodium sulfate solution; then add the sodium sulfate solution to the suspension, stir for 30 minutes to mix evenly, and obtain a mixed solution;

[0080] Slowly raise the temperature of the above mixture to 80-90°C, control the heating rate at 0.5-1.0°C / min, and react at 80-90°C for 3 hours, cool to room temperature, keep stirring for 3 hours, and then slowly heat up to 60-70°C , the heating rate is controlled at 1.0-2.0°C / min, and the layered double metal hydroxide is obtained. The mass of the layered double hydroxide after drying was 160 g, and a suspension of the layered double hydroxide with a mass c...

Embodiment 3

[0084] (1) Preparation of layered double metal hydroxides

[0085] In a 2L beaker, add 1.0mol aluminum hydroxide and 1.0mol calcium hydroxide respectively, then add 500mL water, stir to mix the aluminum hydroxide and calcium hydroxide uniformly to prepare a suspension; mix 1.0mol sodium carbonate and 500mL Add water into a 1000mL beaker, stir to dissolve completely, and obtain a sodium carbonate solution; add the sodium carbonate solution to the above suspension, stir for 30 minutes to mix evenly, and obtain a mixed solution;

[0086] Slowly raise the temperature of the above mixture to 80-90°C, control the heating rate at 0.5-1.0°C / min, and react at 80-90°C for 3 hours; then cool to room temperature, keep stirring for 3 hours, and then slowly heat up to 60-70°C ℃, the heating rate is controlled at 1.0-2.0 ℃ / min, and the layered double metal hydroxide is obtained. The quality of the layered double metal hydroxide after drying is 160g, and the layered double metal hydroxide wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com