Device and method for preparing high-nitrogen steel powder through plasma arc melting

A plasma arc and plasma arc technology are applied in the field of devices for preparing high nitrogen steel powder by ion arc smelting, and can solve problems such as uneven distribution of nitrogen elements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

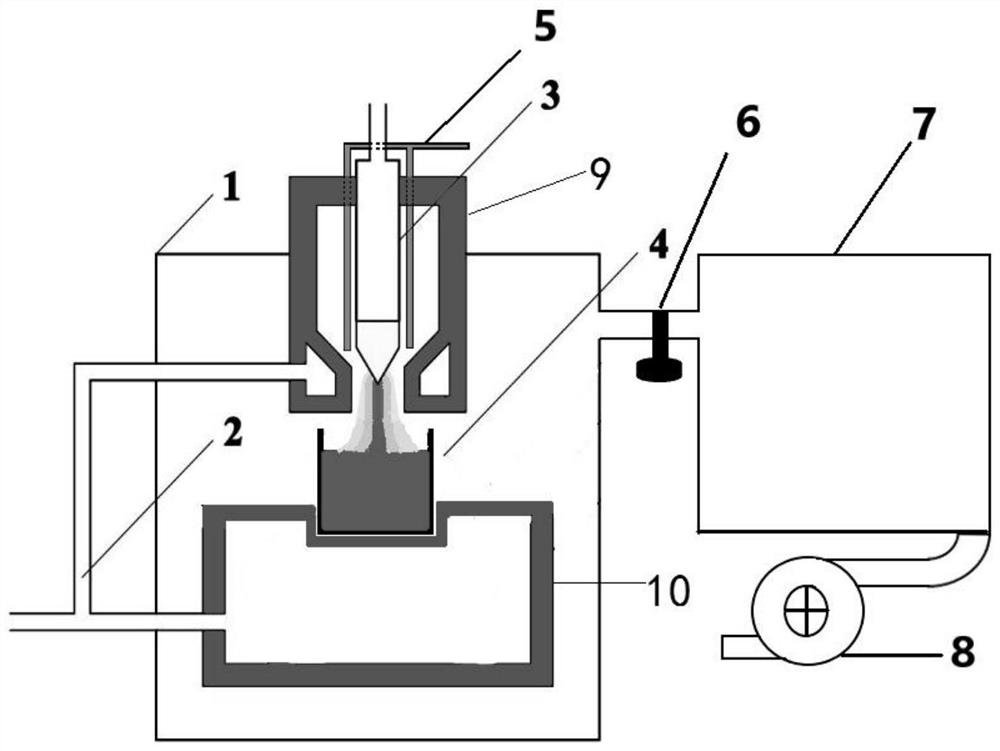

[0049] A method for preparing high-nitrogen steel powder by plasma arc melting, in figure 1 performed in the device shown, figure 1 Among them, 1 is the plasma furnace, 2 is the cooling water assembly, 3 is the tungsten electrode, 4 is the graphite crucible, 5 is the nitrogen conduit, 6 is the vacuum valve, 7 is the vacuum chamber, 8 is the molecular pump, 9 is the water-cooled anode, and 10 is the A heat conduction base (copper crucible), a heat conduction base 10 is placed at the bottom of the plasma furnace 1, a graphite crucible 4 is provided on the top of the heat conduction base 10, and a plasma arc assembly is provided on the vertical direction of the graphite crucible 4, so The plasma arc assembly includes a water-cooled anode 9, a tungsten electrode 3 and a nitrogen gas conduit 5, the nitrogen gas conduit 5 is located between the water-cooled anode 9 and the tungsten electrode 3, and is placed outside the tungsten electrode 3, and the tungsten electrode 3 is located o...

Embodiment 2

[0059] Same as Embodiment 1, the only difference is that the device does not contain vacuum valve vacuum chamber and molecular pump.

[0060] Specific steps are as follows:

[0061] Step 1: Assemble the plasma furnace, cooling water assembly, tungsten electrode, graphite crucible, nitrogen conduit, water-cooled anode and copper crucible;

[0062] Step 2: Place steel powder (particle size 20-200 μm) in a graphite crucible, vacuumize the plasma furnace and fill it with argon, and the distance between the tungsten electrode and the metal raw material is 5 mm;

[0063] Step 3: Start the tungsten electrode and perform plasma arc melting on the steel powder in the graphite crucible;

[0064] Step 4: When the steel powder is molten, the nitrogen conduit is turned on (the flow rate of the nitrogen gas is 10L / min, and the nitrogen gas is ionized. After the plasma arc melting, the surface of the molten steel begins to evaporate, and nitrogen-containing metal vapor is obtained. The nitr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com