A gray effect yarn or fabric and its preparation method and application

A yarn and fabric technology is applied in the field of preparation of cationic modified cotton and nanofibers to achieve gray spinning effect, which can solve the problems of uneven combination of cotton fibers and dyes, and the effect of gray yarn is not obvious, and achieves good hand feel , the effect of shortening production time and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

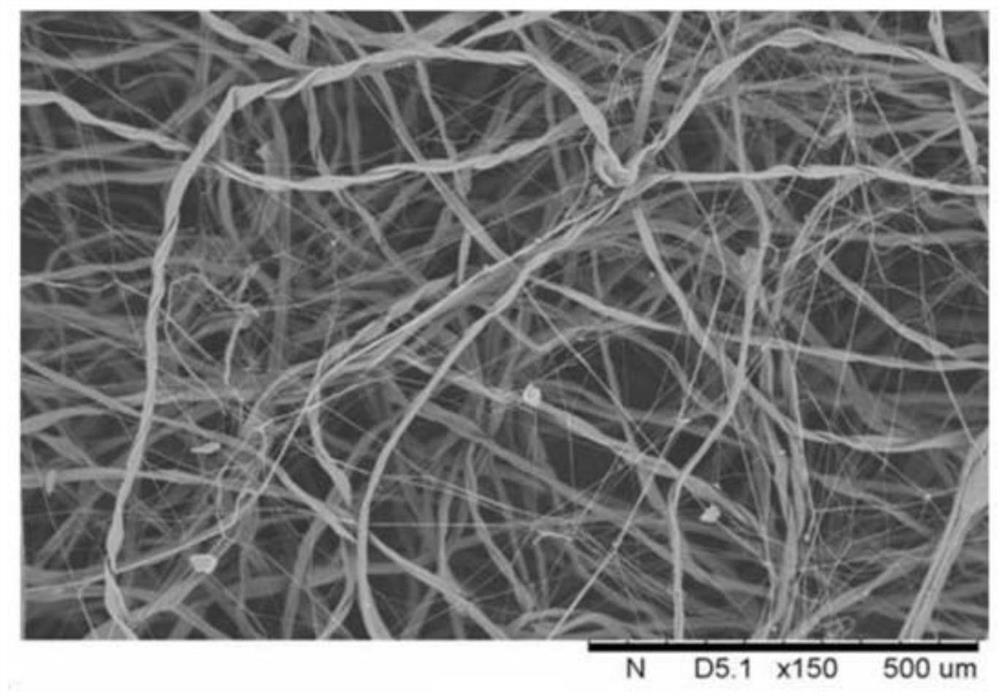

[0036] In this embodiment, the spinning raw material adopts commercially available cotton staple fibers, preferably raw cotton with a length of more than 30 mm, the model is L233A, the polymer of the electrospinning solution is selected from polyacrylonitrile (molecular weight is 85000), and the solvent is N, N— Dimethylformamide (DMF), the cationic modifier is 2,3-epoxypropyl trimethyl ammonium chloride, and the dyeing agent is acid reactive dye yellow RC-3R2% (OWF).

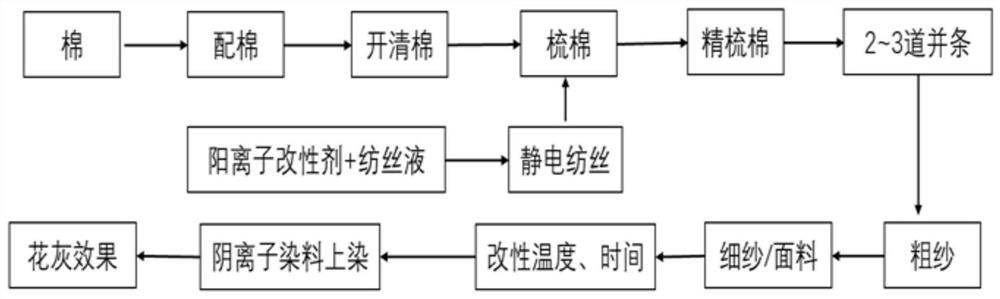

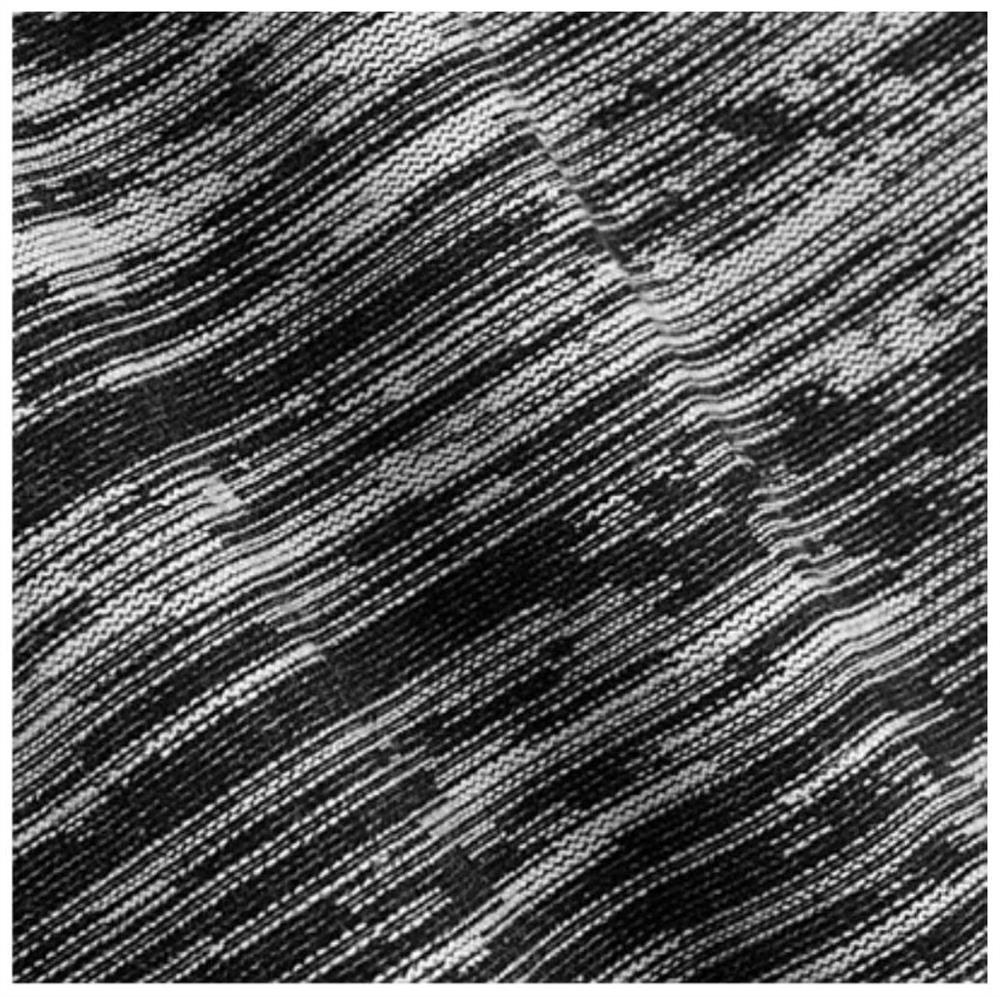

[0037] In this embodiment, the process method of cationic modified cotton and nanofibers to achieve the effect of gray spinning is to obtain gray yarn and fabric through normal spinning and dyeing and finishing processes combined with electrospinning process. The specific steps are as follows:

[0038] Step 1: Mix raw cotton staple fibers with cotton, and then carry out the cotton opening and cleaning process to make uniform cotton laps. After opening and cleaning, the impurity content of the laps is controlled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com