Duplex large-capacity disc-stacking multi-roll liquid filtering machine

A technology of double-connected large and stacked discs, applied in the fields of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of narrow feed concentration range, waste of water resources, large waste of flushing water, etc., and achieve the applicable material concentration range. The effect of reducing the area, reducing the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

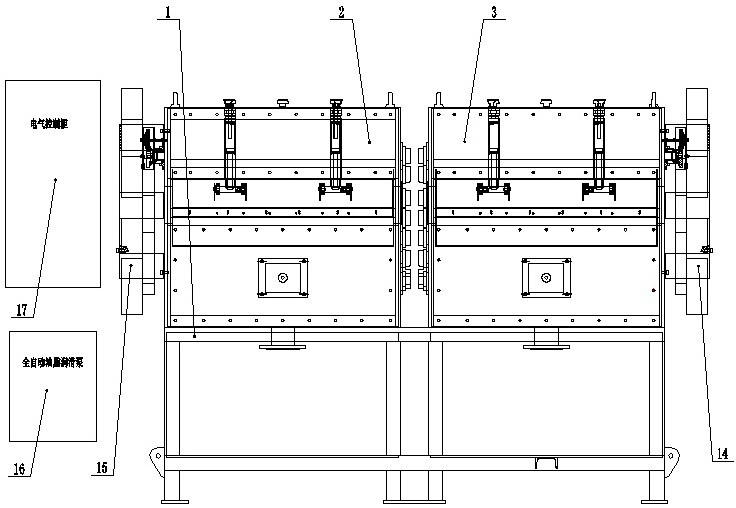

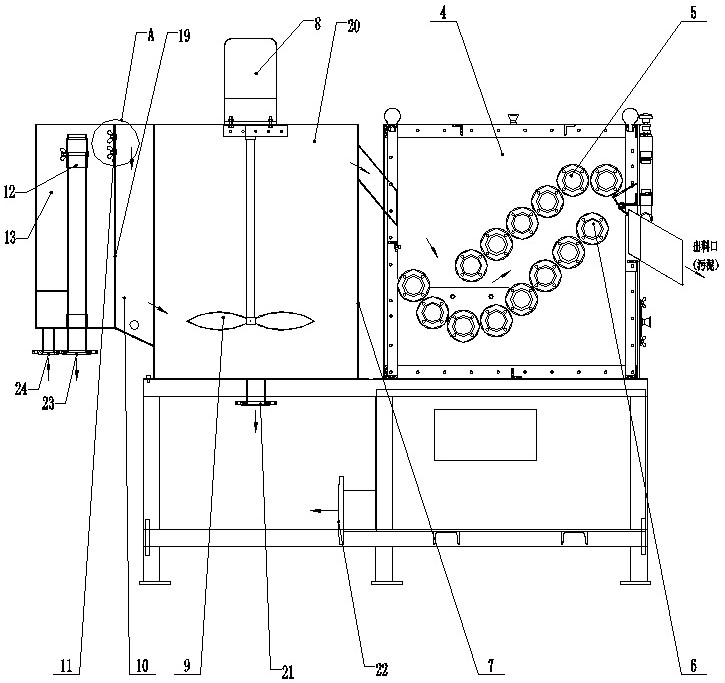

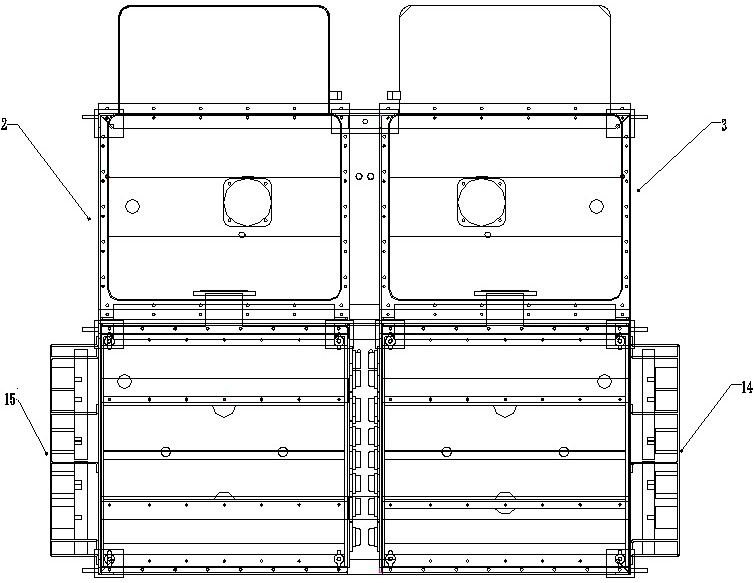

[0022] Refer to attached Figure 1-4 As shown, the double-connected large-capacity stacked disc multi-roller filtrate machine of the present invention includes a frame 1, and two stand-alone machines, a left side machine 2 and a right side machine 3, are installed on the frame 1, and a left transmission system is installed on the left side machine 2 15, right transmission system 14 is installed on the right side machine 3. Two stand-alone machines of the left side machine 2 and the right side machine 3 comprise the main frame 4 respectively, and each main frame 4 is equipped with an upper stacked disc roller group 5 and a lower stacked disc roller group 6, respectively by the left transmission system 15 and the right transmission system. 14 is driven to rotate, and the material that enters the main box 4 from the metering mixing mixing box is squeezed and removed between the upper stacked roller group 5 and the lower stacked roller group 6, and the lower part of the main box 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com