Preparation method of Bi/BiVO4-CdS photocatalyst rich in oxygen vacancies

A photocatalyst, oxygen vacancy technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., to achieve good economic and environmental benefits, high degradation efficiency, improved light Effects of Corrosion Problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] BiVO 4 Preparation of:

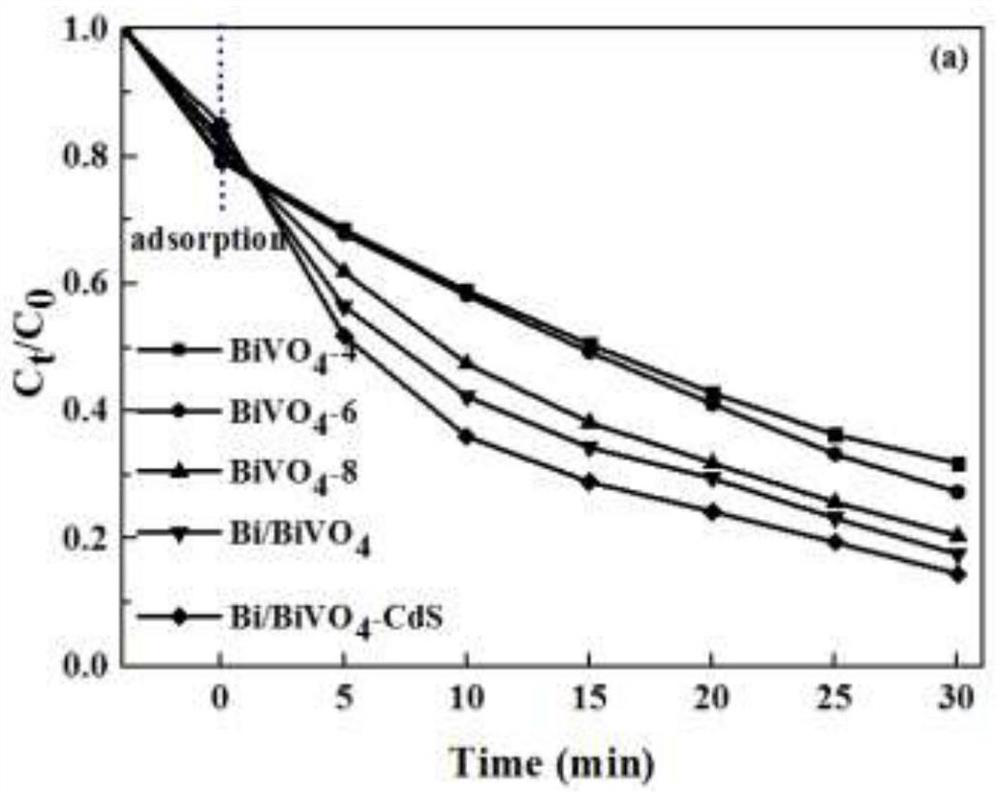

[0048] Disperse 50-80 mg of bismuth nitrate pentahydrate in 40-45 mL of deionized water, sonicate for 10-20 minutes, and then stir evenly for 20-30 minutes. Subsequently, 90-110 mg of sodium orthovanadate was added to the mixed solution. After stirring for 1-2 hours, the solution was transferred to a hydrothermal reaction kettle and kept at 160° C. for 2, 4, 6, and 8 hours, respectively. The yellow powder was washed more than 3 times with deionized water and absolute ethanol to obtain BiVO 4 -2. BiVO 4 -4. BiVO 4 -6. BiVO 4 -8.

[0049] Bi / BiVO 4 Preparation of:

[0050] 0.125-0.140g of BiVO 4 -8 was dispersed in 25mL deionized water and stirred evenly for 10-20 minutes. Then, under vigorous stirring, 13mL NaBH 4 The solution was slowly added dropwise to the above solution (NaBH 4 / BiVO 4 Molar ratio = 0.18-0.22). After stirring for 1-2 hours, the solution was kept for 1-2 hours. The precipitate was thoroughly washed several times...

Embodiment 2

[0057] BiVO 4 Preparation of:

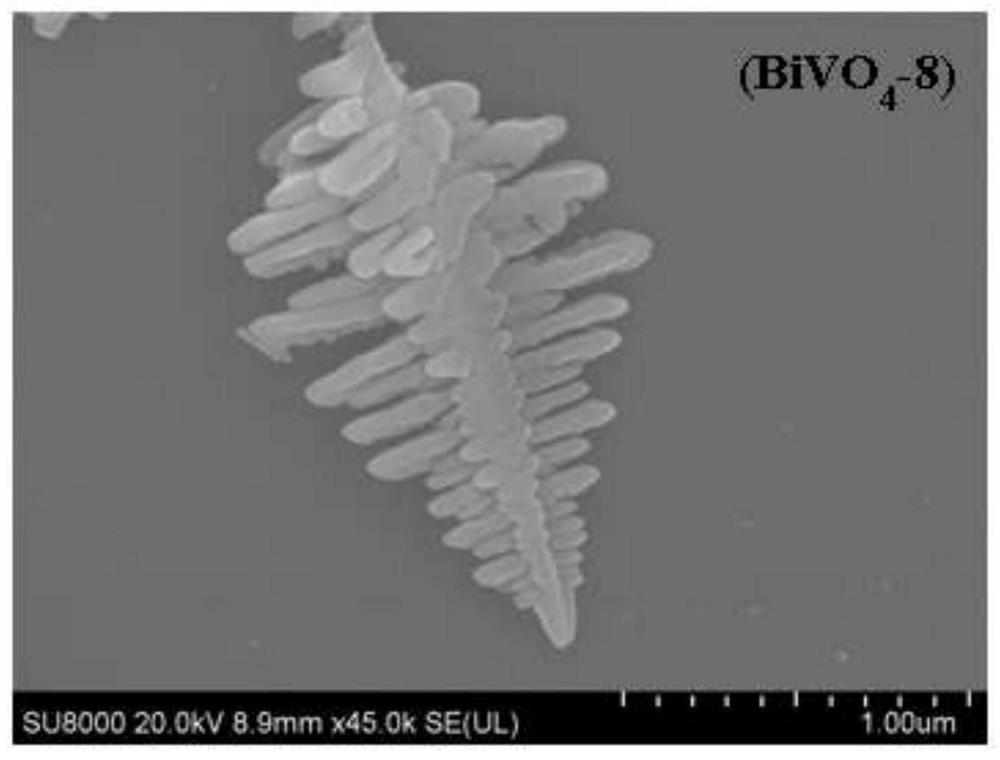

[0058] Disperse 60 mg of bismuth nitrate pentahydrate in 40 mL of deionized water, sonicate for 10 minutes, and then stir evenly for 20 minutes. Subsequently, 100 mg of sodium orthovanadate was added to the mixed solution. After stirring for 1 hour, the solutions were transferred to a hydrothermal reactor and kept at 160 °C for 8 hours respectively. The yellow powder was washed more than 3 times with deionized water and absolute ethanol, such as figure 1 As shown, the BiVO 4 -8. Bi / BiVO 4 Preparation of:

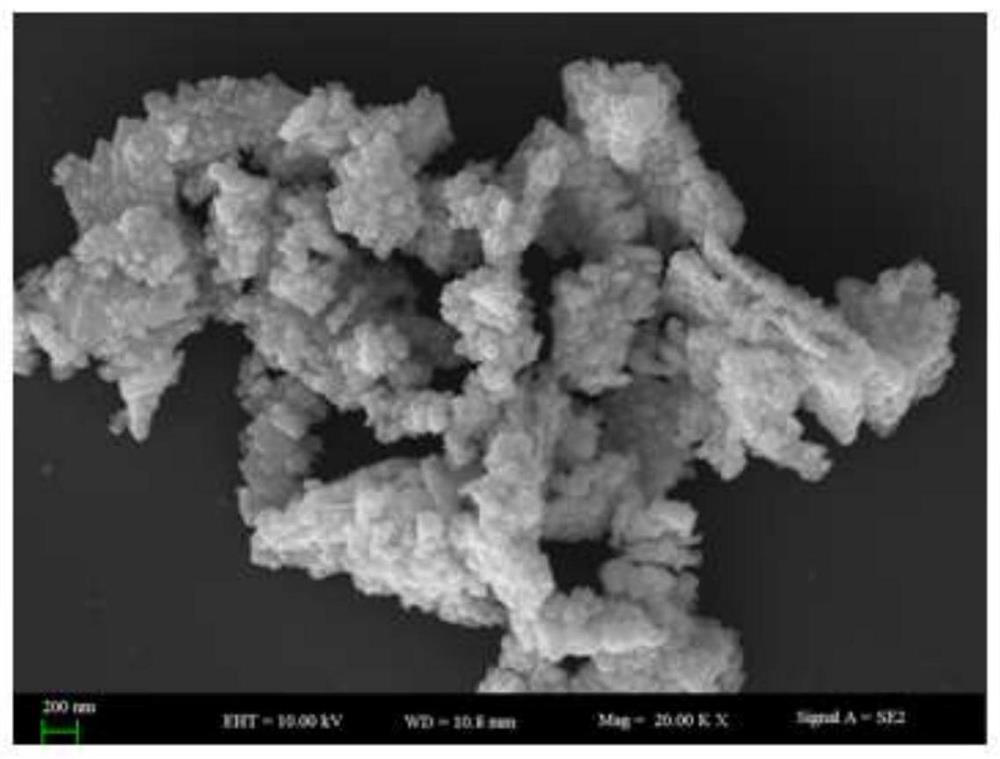

[0059] With BiVO 4 -8 is the substrate, NaBH 4 solution as reducing agent, prepared Bi / BiVO 4 composite material. 0.125gBiVO 4 -8 was dispersed in 25 mL of deionized water and stirred evenly for 20 minutes. Then under vigorous stirring (NaBH 4 / BiVO 4 Molar ratio=0.2) will 13mL NaBH 4 The solution was slowly added dropwise to the above solution. After stirring for 1 hour, the solution was maintained for 1 hour. The precipitate...

Embodiment 3

[0066] BiVO 4 Preparation of:

[0067] Disperse 60 mg of bismuth nitrate pentahydrate in 40 mL of deionized water, sonicate for 10 minutes, and then stir evenly for 20 minutes. Subsequently, 100 mg of sodium orthovanadate was added to the mixed solution. After stirring for 1 hour, the solutions were transferred to a hydrothermal reactor and kept at 160 °C for 8 hours respectively. The yellow powder was washed more than 3 times with deionized water and absolute ethanol to obtain BiVO 4 -8.

[0068] Bi / BiVO 4 Preparation of:

[0069] With BiVO 4 -8 is the substrate, NaBH 4 solution as reducing agent, prepared Bi / BiVO 4 composite material. 0.125gBiVO 4 -8 was dispersed in 25 mL of deionized water and stirred evenly for 20 minutes. Then under vigorous stirring (NaBH 4 / BiVO 4 Molar ratio=0.18) will 13mL NaBH 4 The solution was slowly added dropwise to the above solution. After stirring for 1 hour, the solution was maintained for 1 hour. The precipitate was thorough...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com