High-electron-hole pair separation efficiency composite photocatalyst and preparation method thereof

A technology of recombining light and hole pairs, applied in the field of photocatalysis, can solve the problem of low electron-hole separation rate, achieve the effect of improving electron-hole separation efficiency, enhancing photocatalytic performance, and simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

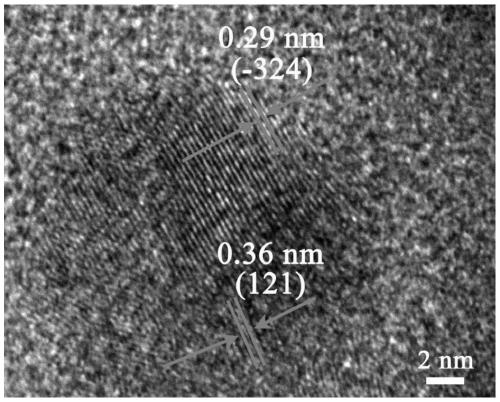

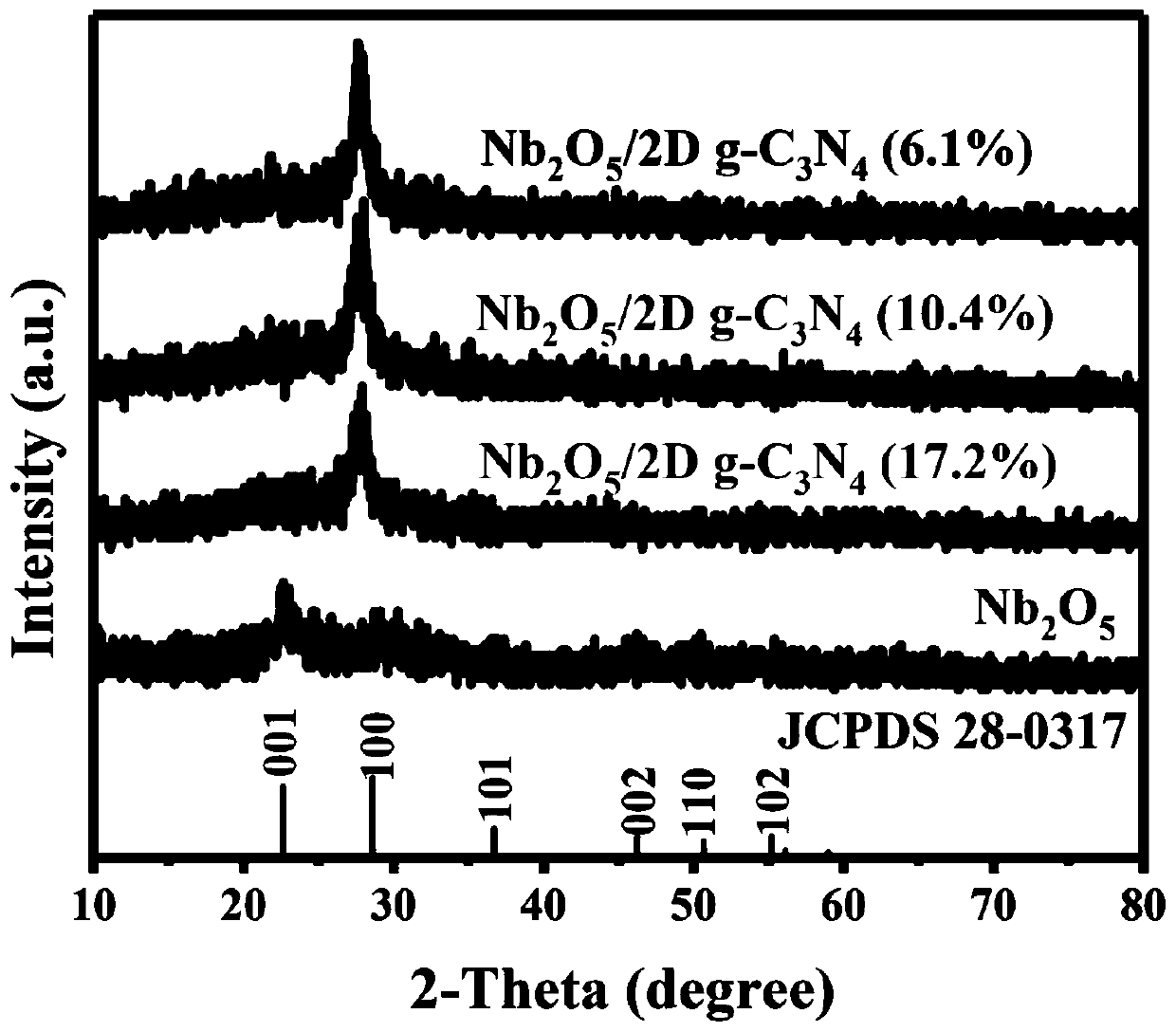

[0020] The present invention is a kind of Nb 2 o 5 / 2D g-C 3 N 4 (6.1%) (Nb 2 o 5 accounted for the entire Nb 2 o 5 / 2Dg-C 3 N 4 6.1% of the mass of the composite photocatalyst) The preparation method of the composite photocatalytic material comprises the following steps: adding the niobium pentoxide nano-sphere flower synthesized by hydrothermal method into the deionized water, stirring for 30min, ultrasonication for 1h, making it stir evenly, and preparing Suspension with a concentration of 0.02 mg / L; add the suspension obtained by adding 2 mL of the above to melamine, stir for 40 min, and make it evenly mixed; then move the evenly stirred mixture to a crucible, put it into a muffle furnace for secondary calcination, The heating rate of the primary calcination is 2°C / min, and it is kept at 550°C for 240 minutes. The heating rate of the second calcination is 10°C / min, and it is kept at 530°C for 100 minutes. The obtained white solid is the Nb 2 o 5 / 2D g-C 3 N 4 (...

Embodiment 2

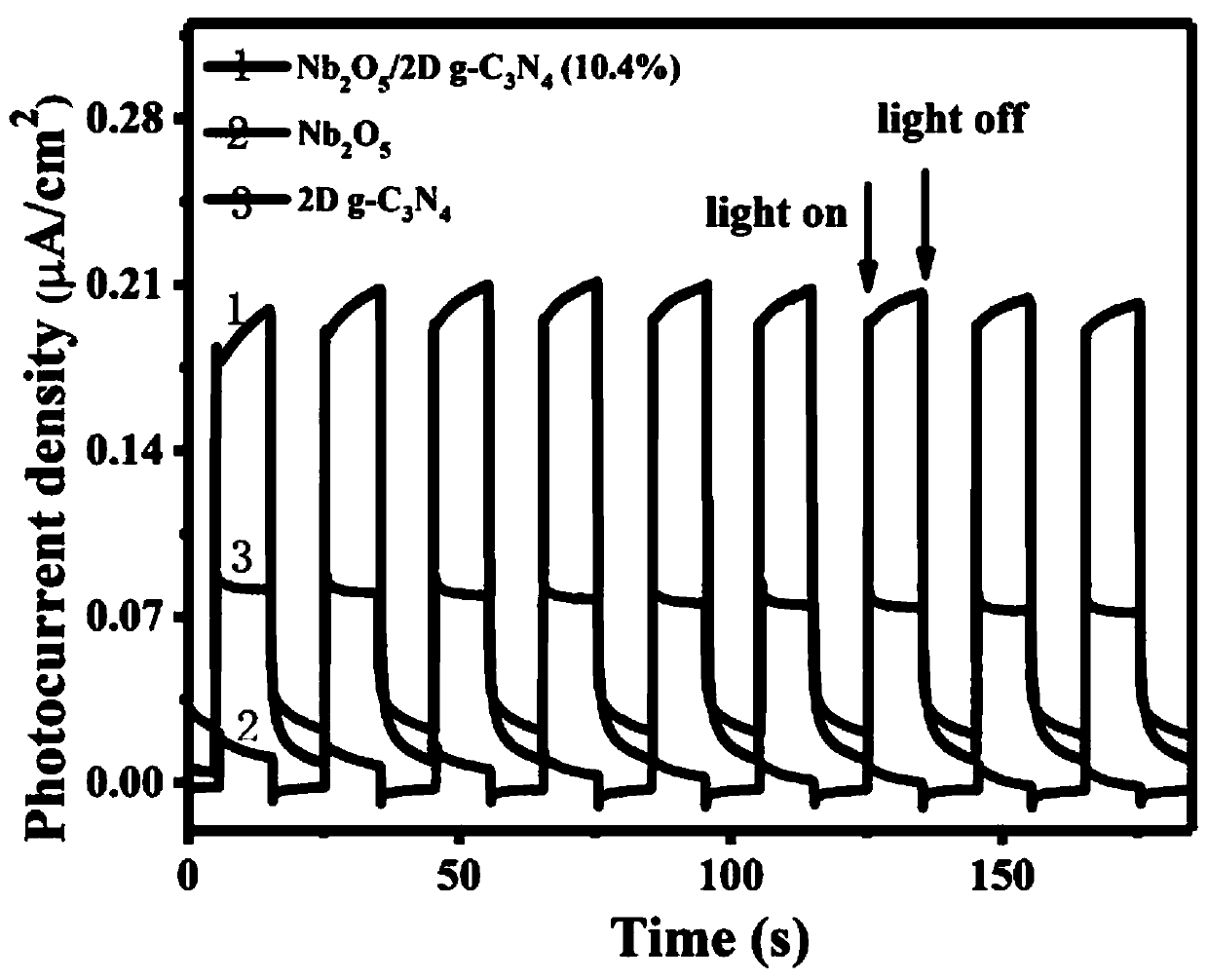

[0022] The present invention is a kind of Nb 2 o 5 / 2D g-C 3 N 4 (10.4%) (Nb 2 o 5 accounted for the entire Nb 2 o 5 / 2Dg-C 3 N 410.4% of the mass of the composite photocatalyst) The preparation method of the composite photocatalytic material comprises the following steps: adding the niobium pentoxide nano-sphere flower synthesized by hydrothermal method into deionized water, stirring for 30min, ultrasonication for 1h, making it stir evenly, and preparing Suspension with a concentration of 0.02 mg / L; add the suspension obtained by adding 4 mL of the above to melamine, stir for 40 min, and make it evenly mixed; then move the evenly stirred mixture to a crucible, put it into a muffle furnace for secondary calcination, The heating rate of the primary calcination is 3°C / min, and it is kept at 550°C for 240 minutes. The heating rate of the second calcination is 15°C / min, and it is kept at 520°C for 120 minutes. The obtained white solid is the Nb 2 o 5 / 2D g-C 3 N 4 (10....

Embodiment 3

[0024] The present invention is a kind of Nb 2 o 5 / 2D g-C 3 N 4 (17.2%) (Nb 2 o 5 accounted for the entire Nb 2 o 5 / 2Dg-C 3 N 4 17.2% of the mass of the composite photocatalyst) The preparation method of the composite photocatalytic material comprises the following steps: adding the niobium pentoxide nano-sphere flower synthesized by hydrothermal method into the deionized water, stirring for 30min, ultrasonication for 1h, making it stir evenly, and preparing Suspension with a concentration of 0.02mg / L; add the above 6mL suspension to melamine, stir for 40min to make it evenly mixed; then move the evenly stirred mixture to a crucible, put it into a muffle furnace for secondary calcination, The heating rate of the primary calcination is 4°C / min, and it is kept at 550°C for 240 minutes. The heating rate of the second calcination is 20°C / min, and it is kept at 510°C for 140 minutes. The obtained white solid is the Nb 2 o 5 / 2D g-C 3 N 4 (17.2%) composite photocatalyt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com