A kind of preparation method of vanadate composite mxene airgel photocatalyst

A photocatalyst and vanadate technology, applied in the field of nanocomposite materials and photocatalysis, can solve the problems of low photocatalytic efficiency, no co-catalyst found, etc., and achieve the effects of high photodegradation efficiency, improved photodegradation efficiency, and high application potential.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

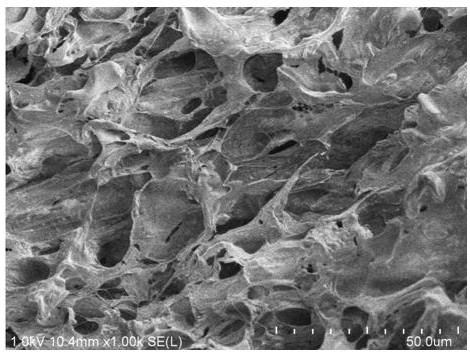

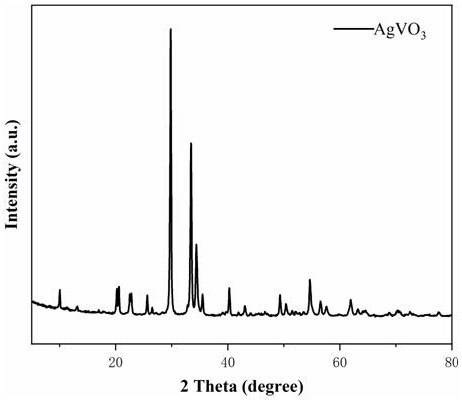

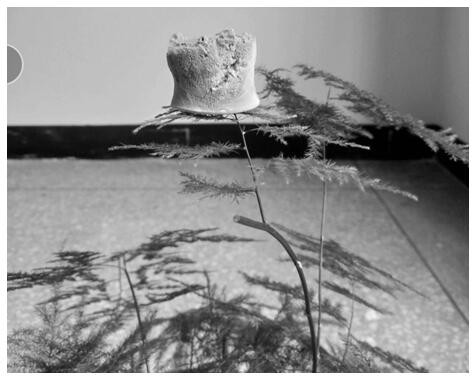

[0025] A kind of preparation method of vanadate composite Mxene airgel photocatalyst, concrete steps are as follows:

[0026] (1) Add 50mg Ti 3 C 2 Mxene was added to 5mL deionized water, Ti 3 C 2 Mxene can be purchased, ultrasonically disperse at room temperature for 10 minutes under the protection of inert gas nitrogen, and then add 6 mg of soluble metal salt silver nitrate, stir at room temperature for 30 minutes before use, and record it as precursor solution A;

[0027] (2) Add 10mg of ammonium metavanadate to 5mL of deionized water, stir at 50°C for 30min, completely dissolve and set aside for use, which is referred to as Precursor B;

[0028] (3) Add the precursor solution B to the precursor solution A dropwise, stir for 1 hour and then transfer it to a polytetrafluoroethylene-lined reactor for reaction. The reaction temperature is 180°C and the reaction time is 24 hours to obtain the hydrogel precursor ;

[0029] (4) Put the hydrogel precursor obtained after the...

Embodiment 2

[0034] A kind of preparation method of vanadate composite Mxene airgel photocatalyst, concrete steps are as follows:

[0035] (1) Add 200mg Ti 3 C 2 Add Mxene to 20mL of deionized water, ultrasonically disperse at room temperature for 20min under the protection of inert gas argon, then add 30mg of soluble metal salt bismuth nitrate, stir at room temperature for 45min before use, and record it as precursor solution A;

[0036] (2) Add 100mg of sodium orthovanadate into 20mL of deionized water, stir at 60°C for 20min, completely dissolve and set aside, record as Precursor B;

[0037] (3) Add Precursor B to Precursor A drop by drop, stir for 1.5 hours, then transfer to a polytetrafluoroethylene-lined reactor for reaction, the reaction temperature is 160°C, and the reaction time is 12 hours;

[0038] (4) Put the hydrogel precursor obtained after the hydrothermal reaction in a dialysis bag (molecular weight cut-off of 3500KD), dialyze in deionized water for 24 hours to remove im...

Embodiment 3

[0040] A kind of preparation method of vanadate composite Mxene airgel photocatalyst, concrete steps are as follows:

[0041] (1) Add 400mg Ti 3 C 2 Add Mxene to 40mL of deionized water, ultrasonically disperse at room temperature for 30min under the protection of inert gas nitrogen, then add 60mg of soluble metal salt indium chloride, stir at room temperature for 60min before use, and record it as precursor solution A;

[0042] (2) Add 100mg of sodium orthovanadate into 40mL of deionized water, stir at 80°C for 10 minutes, completely dissolve and set aside for use, which is referred to as Precursor B;

[0043] (3) Add Precursor B to Precursor A drop by drop, stir for 1 hour, then transfer to a polytetrafluoroethylene-lined reactor for reaction, the reaction temperature is 140°C, and the reaction time is 12 hours;

[0044] (4) Put the hydrogel precursor obtained after the hydrothermal reaction in a dialysis bag (molecular weight cut-off of 3500KD), dialyze in deionized wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com