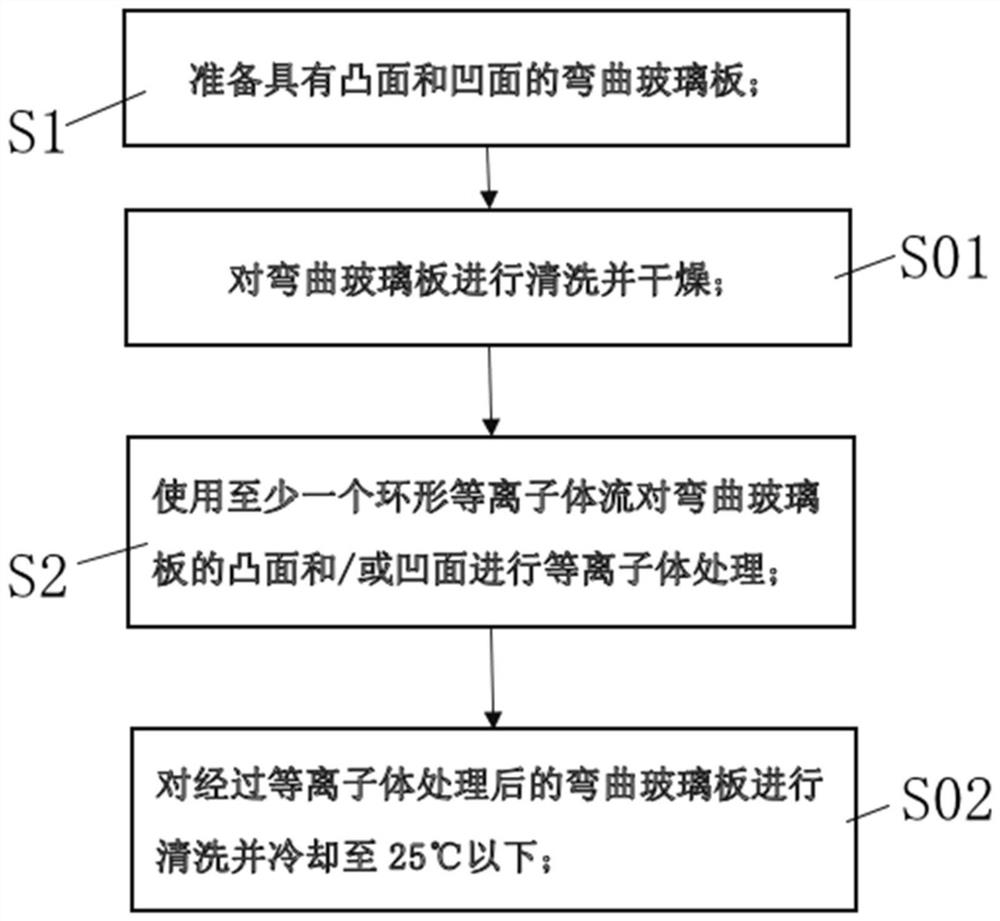

Surface treatment method of a curved glass plate

A technology for surface treatment and glass plate, applied in the surface treatment of curved glass plate and the field of surface cleaning of automobile glass, can solve the problems such as the inability to meet the requirements of coating sol-gel coating on the curved glass plate, and achieve the improvement of processing speed, The effect of improving the wetting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

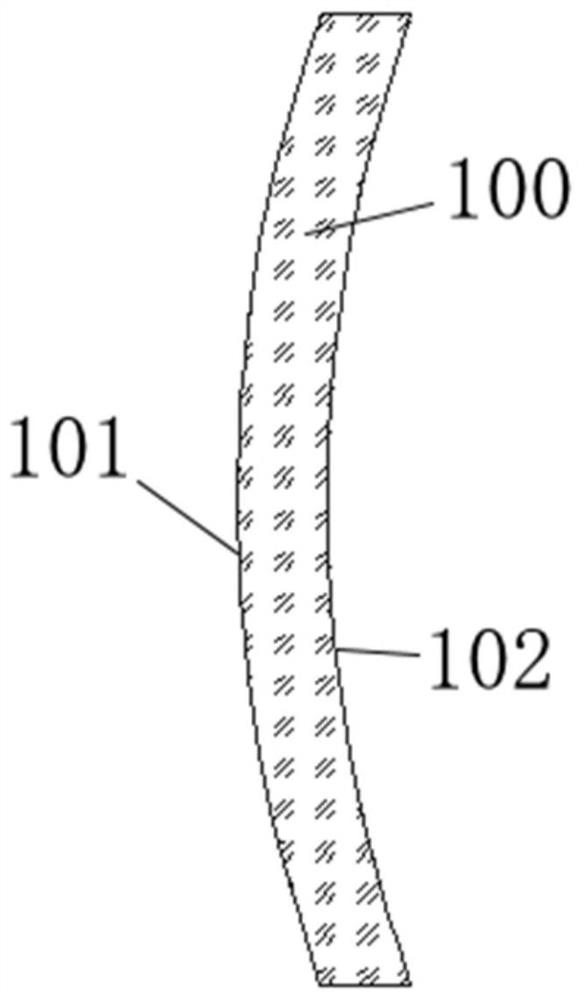

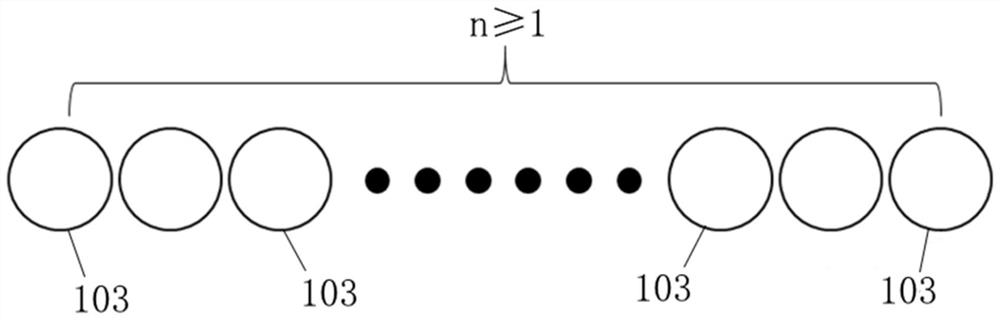

[0052] The plasma generator spray guns with the power of annular plasma flow of 1000W, 850W, 750W and 650W were used to plasma treat the concave surface of the curved glass plate, and the surface water droplets on the concave surface after plasma treatment were measured at different distances and moving speeds. contact angles and are recorded in Table 1. The distance in Table 1 refers to the distance between the torch of the plasma generator and the concave surface of the curved glass sheet.

[0053] Table 1: Plasma Treatment Results for Examples 1-8

[0054] Power (W) Distance(mm) Movement speed (mm / s) Surface droplet contact angle Example 1 1000 15 40 <5° Example 2 1000 15 80 <10° Example 3 850 10 40 <5° Example 4 850 10 80 <10° Example 5 750 10 40 <5° Example 6 750 10 80 <10° Example 7 650 8 40 <5° Example 8 650 8 80 <10°

[0055] It can be seen from Table 1 that under the action ...

Embodiment 9-10 and comparative example 1

[0057] The plasma generator spray gun with a power of 800W of annular plasma flow was selected, and the concave surface of the curved glass plate was 10mm away from the concave surface of the curved glass plate for plasma treatment. The polished concave surface was coated with a coating, and the curved glass plate with the coating was subjected to a boiling resistance test, and the test results were recorded in Table 2.

[0058] In Table 2,

[0059] Polishing treatment: 15% mass fraction of cerium oxide aqueous dispersion, polished with a plane polishing machine;

[0060] Plasma treatment 30mm / s: the power of the annular plasma flow is 800W, the distance between the spray gun of the plasma generator device is 10mm from the concave surface of the curved glass plate, the moving speed of the annular plasma flow is 30mm / s, and the plasma treatment is performed;

[0061] Plasma treatment 10mm / s: the power of the annular plasma flow is 800W, the distance between the spray gun of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com