Image recognition monitoring system for preventing ship touch in offshore oil tanker transportation operation

An image recognition and oil tanker technology, which is applied in the field of ships and ocean engineering, can solve the problems of large pulling force, inconvenient operation, lifting the main engine of the oil tanker, etc., and achieve the effect of improving the judgment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

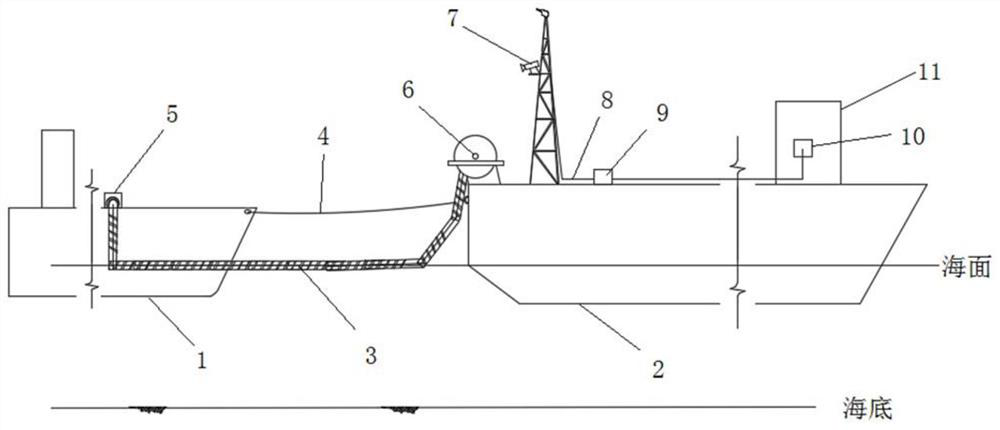

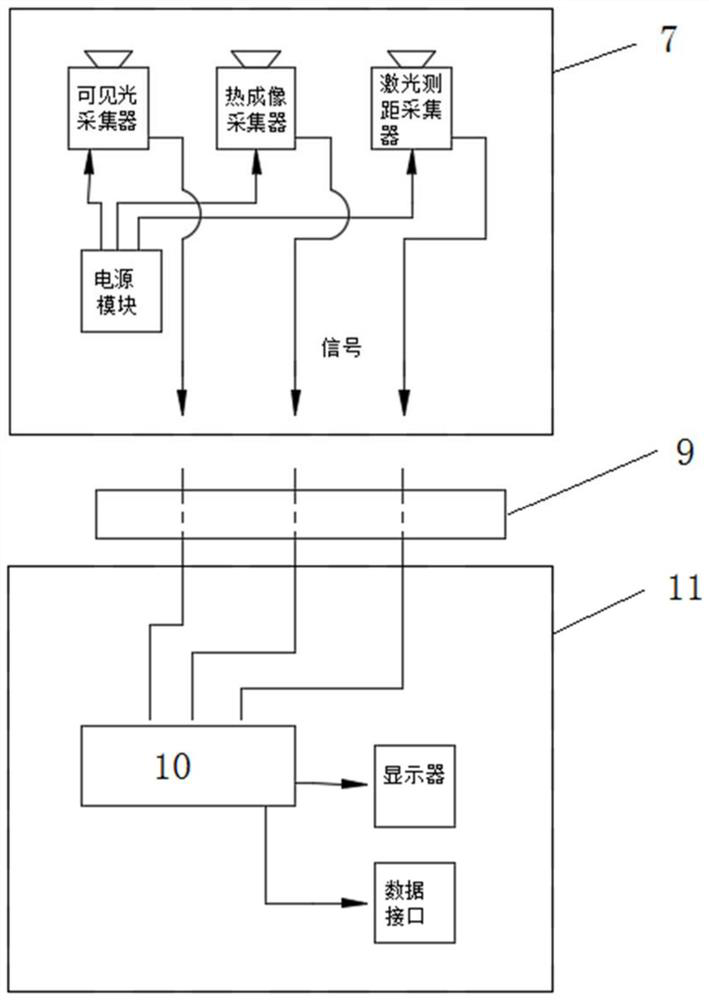

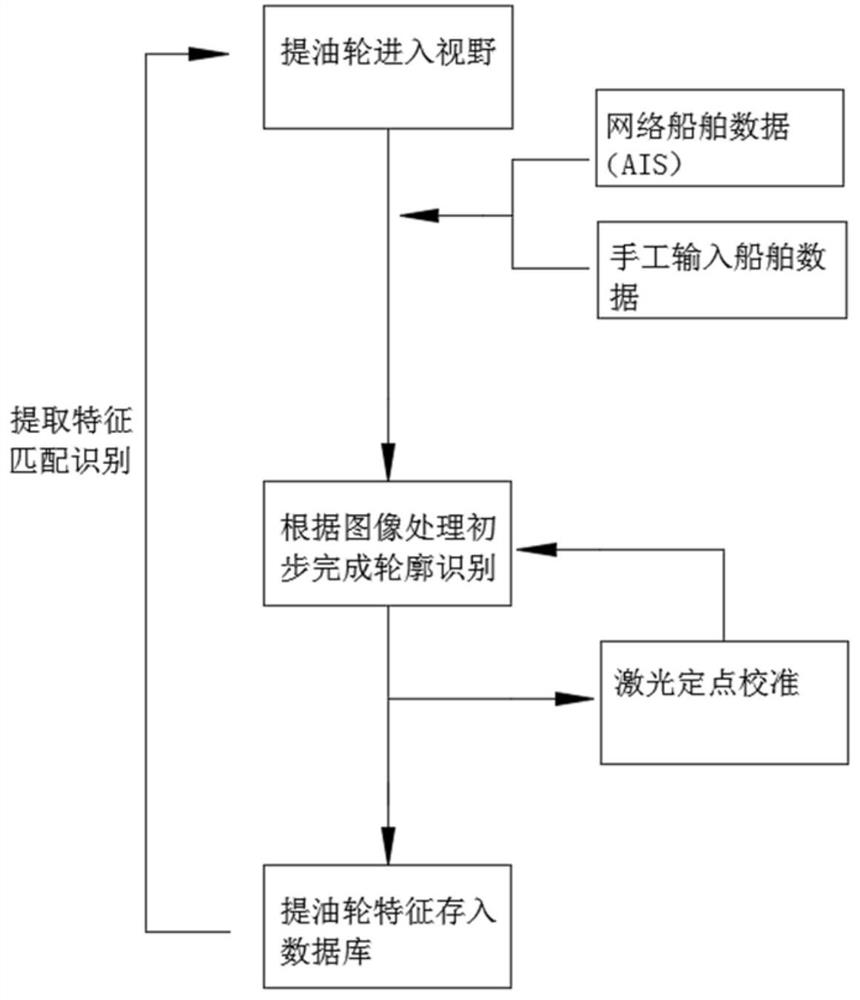

[0026] This embodiment provides an image recognition and monitoring system suitable for preventing ship contact in offshore oil tanker operations, including a collection device 7, a cable 8, a junction box 9, a server 10, image recognition and monitoring software, and an early warning and discrimination system. The collection device includes Visible light collector, thermal imaging collector and laser ranging collector; server 10 is installed in the control room 11 of floating production storage and offloading unit (FPSO), including mainframe, display, mouse and keyboard, and server 10 is also installed with Image recognition monitoring software and database; the image recognition mon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com