A kind of preparation method of high-purity, low-cost molybdenum disilicide

A molybdenum disilicide, low-cost technology, used in metal silicide, chemical industry, sustainable manufacturing/processing, etc., can solve the problems of low purity, unable to reach high-purity standards, affecting product purity, etc., and achieve high product purity. , low cost, reasonable and controllable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

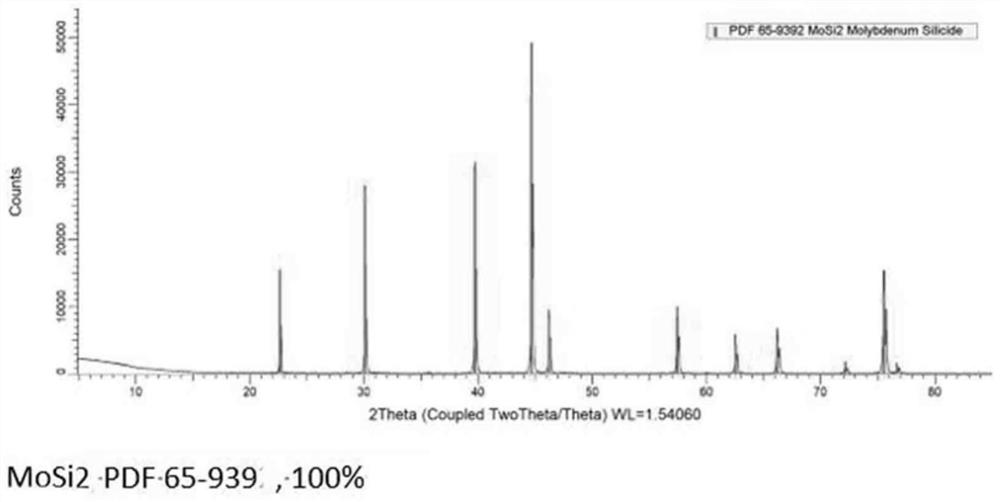

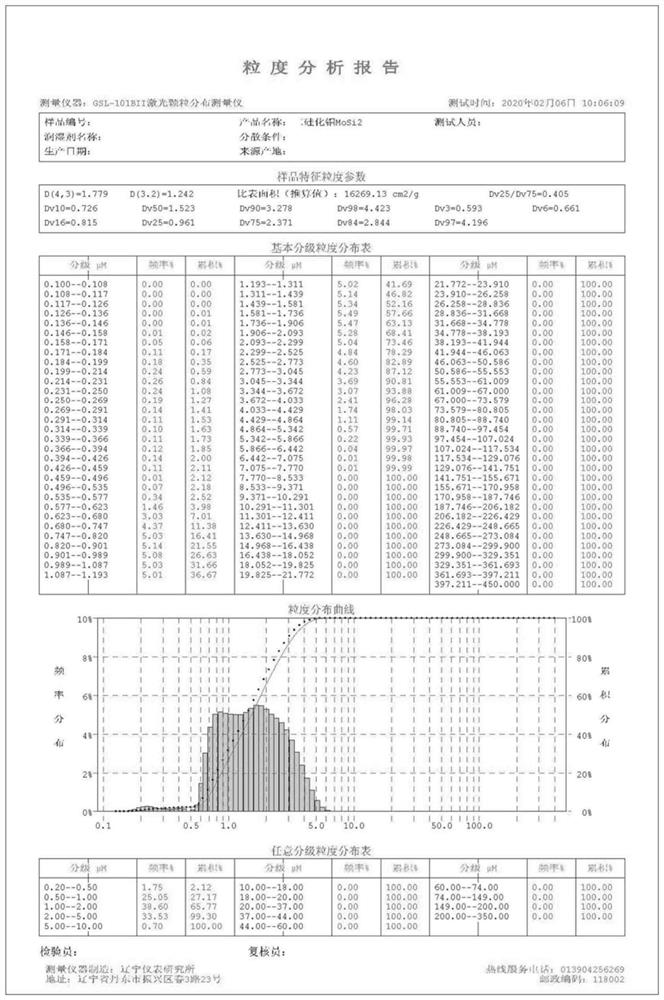

Image

Examples

Embodiment 1

[0027] (1) The raw material molybdenum trioxide 41.34 kg, silica 34.51 kg and high-purity graphite powder 24.15 kg, added carboxymethyl cellulose 1 kg, mixed in a 250 liter V-type mixer, the molybdenum trioxide purity of 99.5%, particle size of 325 mesh, silica purity of 99.8%, particle size of 400 mesh, high-purity graphite purity of 99.99%, particle size of 325 mesh, mixing 6.5 hours, to obtain the mixed material;

[0028] (2) The mixed material obtained in step (1) is pressed according to 1 kg per part, and the pressing pressure is 30MPa, and the pressing pressure is 30MPa, and the compaction is not loose, and the pressing density is ≥ 3.2g / cm 3 , to obtain the pressed block material;

[0029] (3) The pressed block material is vacuum sintered with 500 kg vacuum pressureless sintering furnace, and the whole vacuum sintering process is continuously vacuumed, and the amount of each charging is 200 kg;

[0030] (1) The first heating up

[0031] Turn on the power supply, send the po...

Embodiment 2

[0038] (1) The raw material molybdenum trioxide 41.34 kg, silica 34.51 kg and high-purity graphite powder 24.15 kg, add carboxymethyl cellulose 1 kg, mixed in a 250 liter V-type mixer, the molybdenum trioxide purity of 99.5%, particle size of 325 mesh, silica purity of 99.8%, particle size of 400 mesh, high purity graphite purity of 99.99%, particle size of 325 mesh, mixing 7.5 hours, to obtain the mixed material;

[0039] (2) The mixed material obtained in step (1) is pressed according to 1 kg per part, and the pressing pressure is 30MPa, and the pressing pressure is 30MPa, and the compaction is not loose, and the pressing density is ≥ 3.2g / cm 3 , to obtain the pressed block material;

[0040] (3) The pressed block material is vacuum sintered with 500 kg vacuum pressureless sintering furnace, and the whole vacuum sintering process is continuously vacuumed, and the amount of each charging is 200 kg;

[0041] (1) The first heating up

[0042]Turn on the power supply, send electrici...

Embodiment 3

[0048] (1) The raw material molybdenum trioxide 41.34 kg, silica 34.51 kg and high-purity graphite powder 24.15 kg, added carboxymethyl cellulose 1 kg, mixed in a 250 liter V-type mixer, the molybdenum trioxide purity of 99.5%, particle size of 325 mesh, silica purity of 99.8%, particle size of 400 mesh, high purity graphite purity of 99.99%, particle size of 325 mesh, mixing for 7 hours, to obtain the mixed material;

[0049] (2) The mixed material obtained in step (1) is pressed according to 1 kg per part, and the pressing pressure is 30MPa, and the pressing pressure is 30MPa, and the compaction is not loose, and the pressing density is ≥ 3.2g / cm 3 , to obtain the pressed block material;

[0050] (3) The pressed block material is vacuum sintered with 500 kg vacuum pressureless sintering furnace, and the whole vacuum sintering process is continuously vacuumed, and the amount of each charging is 200 kg;

[0051] (1) The first heating up

[0052]Turn on the power supply, send the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com