A kind of cysteamine derivative and its preparation method and application as carbon steel pickling corrosion inhibitor

A technology of cysteamine and derivatives, which is applied in the field of cysteamine derivative corrosion inhibitors and their preparation, can solve the problems of high toxicity and environmental pollution, and achieve the effects of high corrosion inhibition rate, small dosage and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

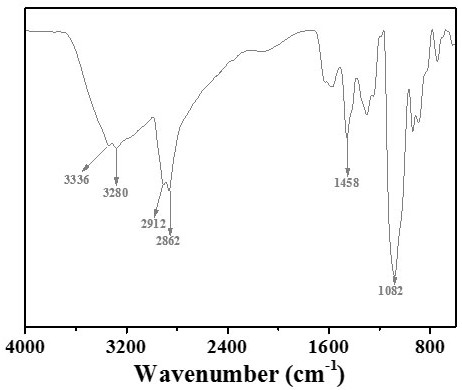

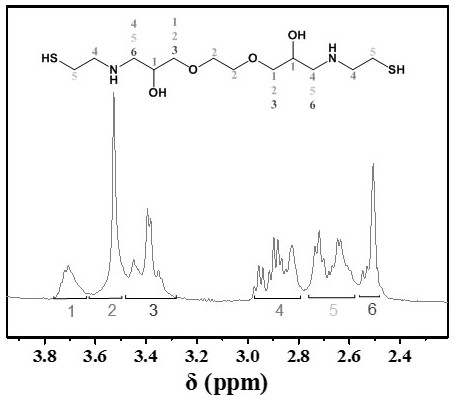

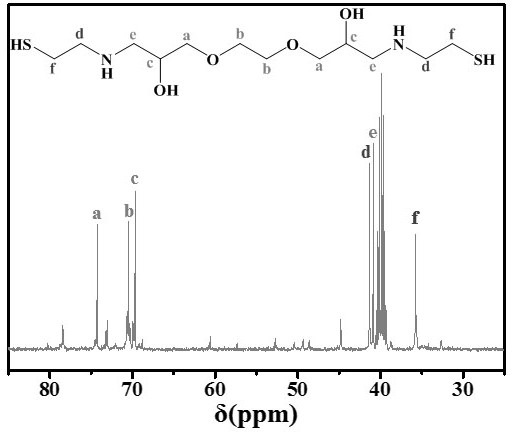

Embodiment 1

[0039] A preparation method for cysteamine derivatives, specifically: add cysteamine (77 g) and ethylene glycol diglycidyl ether (87 g) in a round-bottomed flask, add 150 mL of methanol as a solvent, and control the reaction temperature to 20°C, stirred for 3 h. After the reaction was completed, the solvent was distilled off under reduced pressure, and 131.5 g of a brown solid was obtained after washing with acetone, which was a cysteamine derivative, and the yield was 80.5%.

Embodiment 2

[0041] A preparation method of cysteamine derivatives, specifically: add cysteamine (77 g) and ethylene glycol diglycidyl ether (87 g) in a round bottom flask, add 150 mL of ethanol as a solvent, and control the reaction temperature to 20°C, stirred for 3 h. After the reaction was completed, the solvent was distilled off under reduced pressure, and 128.9 g of a brown solid was obtained after washing with acetone, which was a cysteamine derivative, and the yield was 78.6%.

Embodiment 3

[0043] A preparation method of cysteamine derivatives, specifically: add cysteamine (77 g) and ethylene glycol diglycidyl ether (87 g) in a round bottom flask, add 150 mL of ethanol as a solvent, and control the reaction temperature to 10°C, stirred for 5 h. After the reaction was completed, the solvent was distilled off under reduced pressure, and 136.0 g of a brown solid was obtained after washing with acetone, which was a cysteamine derivative, and the yield was 82.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com