Mixed working medium containing fluoroethane and trifluoroethylene

A technology of trifluoroethylene and working medium, applied in the chemical industry, heat exchange materials, chemical instruments and methods, etc., can solve the problems of ammonia poisonous, flammable and explosive, etc., achieve small flow resistance, excellent environmental performance, refrigeration The effect of high cycle performance coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

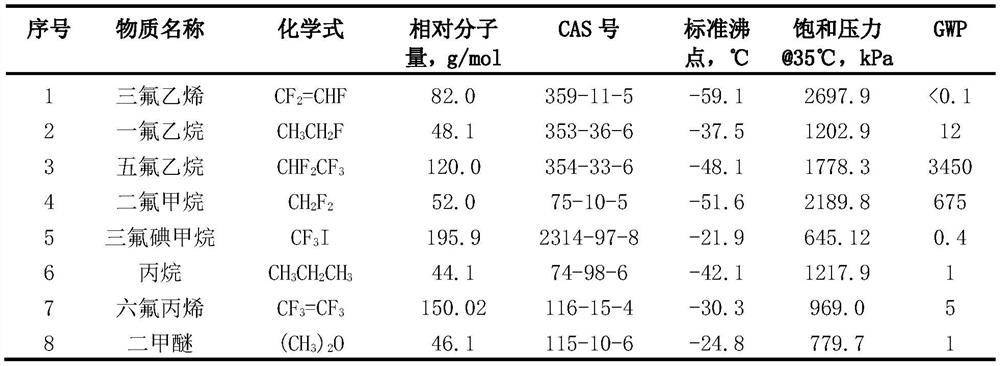

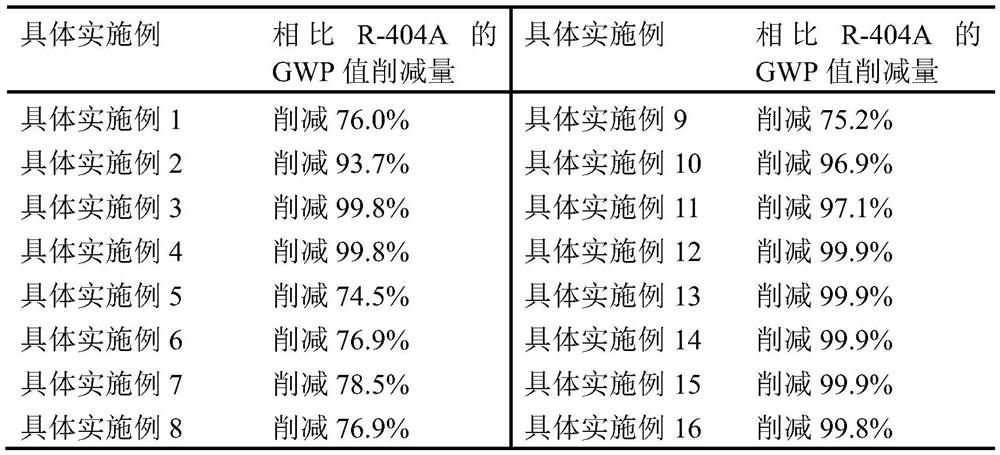

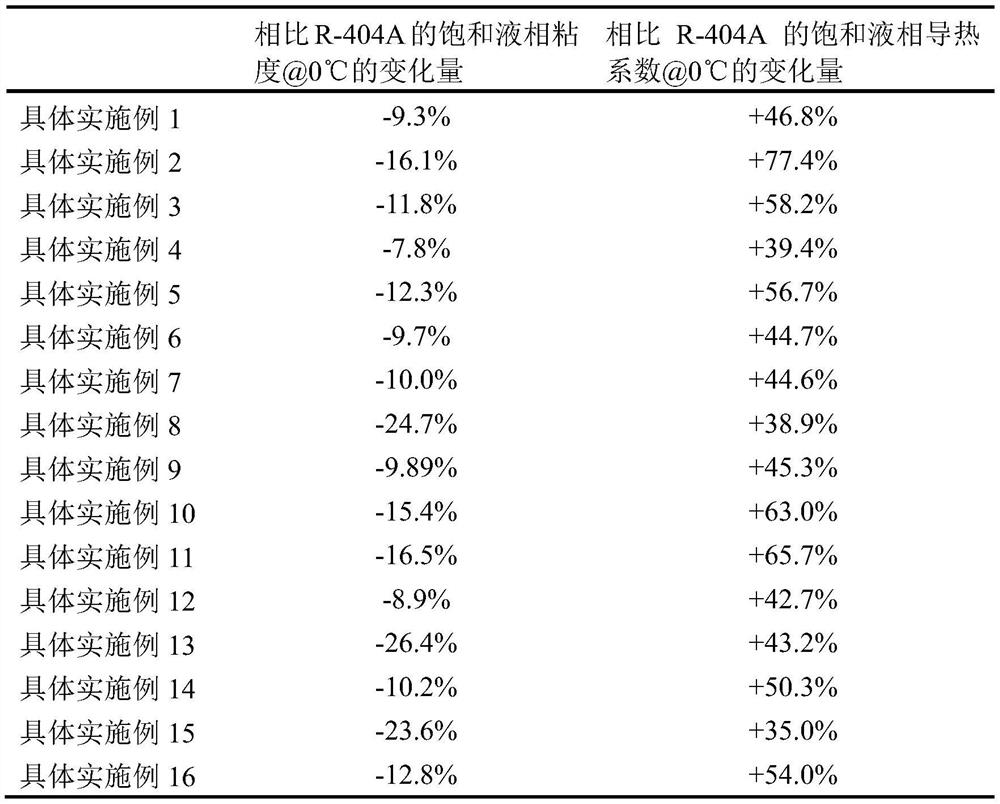

Method used

Image

Examples

specific Embodiment 1

[0023] The first component (trifluoroethylene) accounts for 25.0% of the total mass of the mixture, the second component (monofluoroethane) accounts for 47.0% of the total mass of the mixture, and the third component (pentafluoroethane) accounts for 25.0% of the total mass of the mixture. 28.0%. The relative molecular mass of this mixture is about 66.9 g / mol.

specific Embodiment 2

[0025] The first component (trifluoroethylene) accounts for 5.0% of the total mass of the mixture, the second component (monofluoroethane) accounts for 57.0% of the total mass of the mixture, and the third component (difluoromethane) accounts for 38.0% of the total mass of the mixture %. The relative molecular mass of this mixture is about 50.6 g / mol.

specific Embodiment 3

[0027] The first component (trifluoroethylene) accounts for 23.0% of the total mass of the mixture, the second component (fluoroethane) accounts for 65.0% of the total mass of the mixture, and the third component (iodomethane trifluoromethane) accounts for 65.0% of the total mass of the mixture. 12.0%. The relative molecular mass of the mixture is about 59.0 g / mol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com