High-purity enzyme modified stevioside and preparation method thereof

A stevioside, high-purity technology, applied in the field of stevioside, can solve the problems of uneven purity of stevioside, limitation of stevioside, complicated operation, etc., and achieve the effect of improving the taste, expanding the scope of application, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

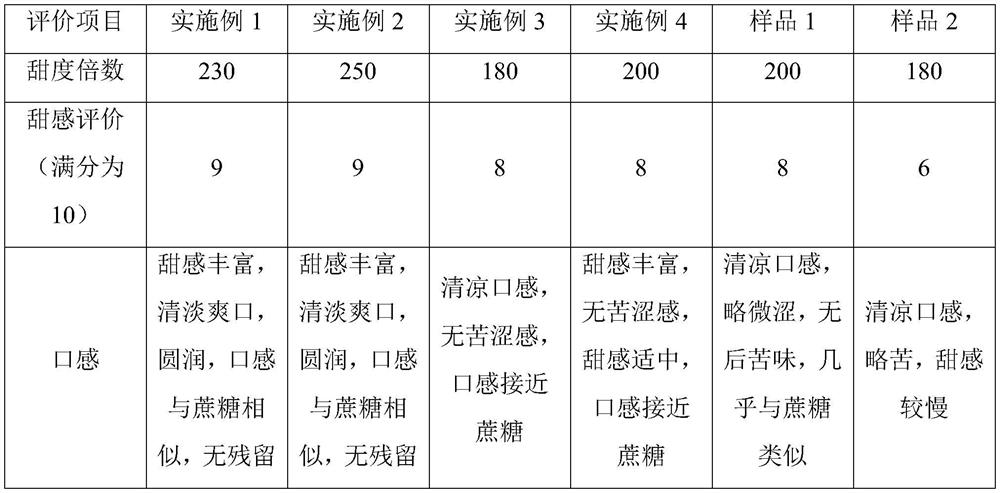

Examples

Embodiment 1

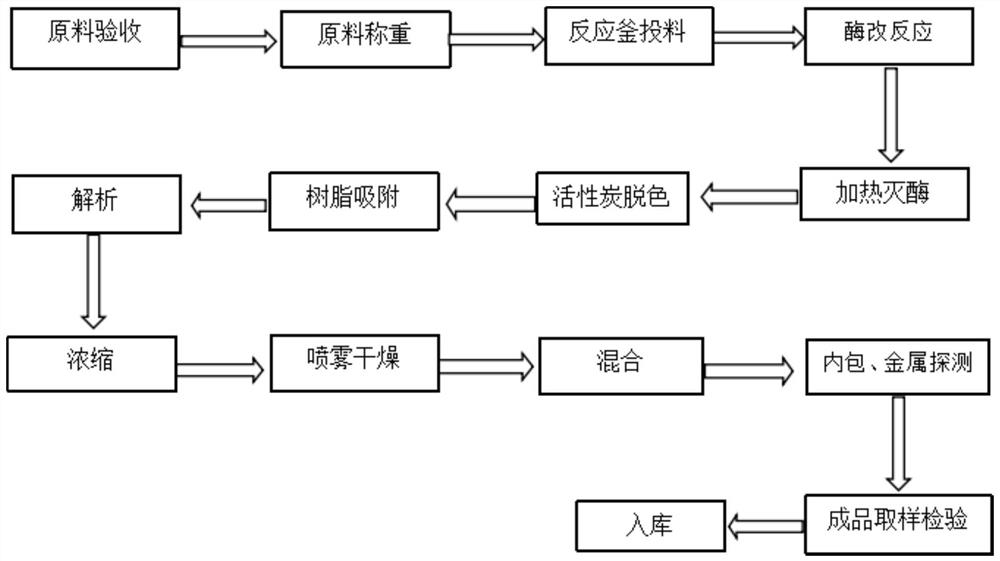

[0038] Step S1: Dissolve steviol glycosides and cyclodextrin in water at a mass ratio of 1:1.2, and the mass concentration of steviol glycosides is 10%;

[0039] Step S2: Add cyclodextrin glucosyl invertase to the solution of step S1, the addition amount is 2% of the addition amount of steviol glycosides, and stir evenly;

[0040] Step S3: React the solution of step S2 at 65°C for 28 hours;

[0041] Step S4: After the reaction of step S3 is completed, add cyclodextrin to continue the reaction for 5 hours, and the added amount is 12% of the amount of cyclodextrin in step S1;

[0042] Step S5: heating the reactant in step S4 to 95°C to inactivate the enzyme;

[0043] Step S6: After cooling, the reaction solution of step S5 is filtered with activated carbon to remove color and impurities;

[0044] Step S7: The solution obtained in step S6 is formulated into a solution with a mass concentration of 3%, and the adsorption resin is oversized until the solution is completely adsorbed at a flow r...

Embodiment 2

[0048] Step S1: Dissolve steviol glycosides and cyclodextrin in water at a mass ratio of 1:1, and the mass concentration of steviol glycosides is 12%;

[0049] Step S2: Add cyclodextrin glucosyl invertase to the solution of step S1, the addition amount is 2% of the addition amount of steviol glycosides, and stir evenly;

[0050] Step S3: React the solution of step S2 at 68°C for 30 hours;

[0051] Step S4: After the reaction of step S3 is completed, add cyclodextrin to continue the reaction for 5 hours, and the added amount is 12.5% of the amount of cyclodextrin in step S1;

[0052] Step S5: heating the reactant in step S4 to 95°C to inactivate the enzyme;

[0053] Step S6: After cooling, the reaction solution of step S5 is filtered with activated carbon to remove color and impurities;

[0054] Step S7: The solution obtained in step S6 is prepared into a solution with a mass concentration of 4%, and the adsorption resin is oversized until the solution is completely adsorbed. The flow r...

Embodiment 3

[0058] Step S1: Dissolve steviol glycosides and maltodextrin in water at a mass ratio of 1:0.5, and the mass concentration of steviol glycosides is 1%;

[0059] Step S2: Add cyclodextrin glucosyltransferase and α-amylase to the solution of step S1 to form a combined enzyme at a mass ratio of 1:1, the addition amount is 1% of the addition amount of steviol glycosides, and the mixture is evenly stirred;

[0060] Step S3: React the solution of step S2 at 60°C for 48 hours;

[0061] Step S4: After the reaction of step S3 is completed, add maltodextrin to continue the reaction for 5 hours, and the added amount is 10% of the amount of maltodextrin in step S1;

[0062] Step S5: heating the reactant in step S4 to 90°C to inactivate the enzyme;

[0063] Step S6: After cooling, the reaction solution of step S5 is filtered with activated carbon to remove color and impurities;

[0064] Step S7: The solution obtained in step S6 is formulated into a solution with a mass concentration of 1%, and the ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com