Off-line drying-out method of hot-blast stove

A method of oven drying and hot blast stove technology, which is applied to furnaces, blast furnaces, brick blast furnaces, etc., and can solve problems such as air and gas temperature reduction, affecting hot blast stove firing and air temperature, and backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

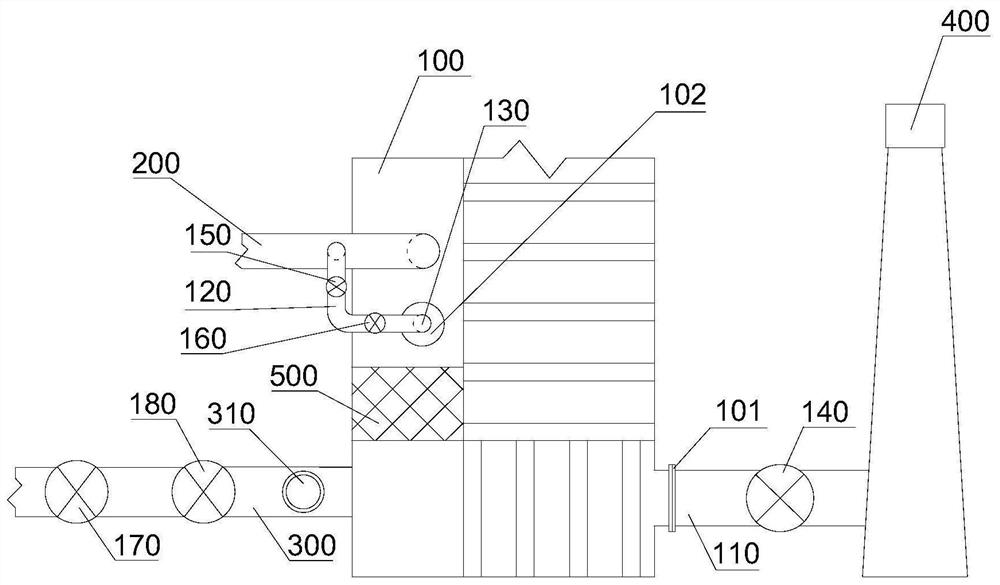

[0077] The off-line oven method of the hot blast stove of this application is in Baowu Group Shaoguan Iron and Steel 3200m 3 Applied to blast furnace internal combustion silica brick hot blast stove.

[0078] Reuse the old stove process pipeline from the first manhole at the bottom of the furnace to the combustion fan, and add another pipeline to the chimney. The diameter of the increased first pipeline is 900mm, equipped with electric butterfly valve and blind plate. The first pipeline connected with the furnace bottom manhole matches the manhole, and has a diameter of 700mm. A second pipeline is laid between the second manhole and the gas main pipe, and the diameter of the second pipeline is 200mm.

[0079] Using a coke oven gas oven, first raise the temperature to 350°C at a heating rate of 1-2°C / h, and keep it at 350°C for 24 hours, then raise the temperature to 700°C at a heating rate of 2-3°C / h, and heat it at 700°C Keep warm at ℃ for 48 hours, then raise the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com