A rapid detection method for the surface structure of nickel-based superalloy forgings, and a high-magnification structure corrosion solution

A nickel-based superalloy and detection method technology, which is applied in the field of high-magnification structure corrosion solution and rapid detection of the surface structure of nickel-based superalloy forgings, can solve the problems of missing abnormal grain structure, inspection is not in place, etc., so that the corrosion surface is clearly visible, Effect of reducing material loss and improving inspection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] In some preferred embodiments, the preparation method of the low-magnification tissue corrosion solution comprises: copper sulfate pentahydrate, concentrated H 2 SO 4 and HCl were added in turn, mixed evenly and set aside.

[0067] In some embodiments, the order of adding the components in the preparation of the low-magnification tissue corrosion solution is copper sulfate pentahydrate, concentrated sulfuric acid, and hydrochloric acid, and the mixture is stirred evenly to obtain the low-magnification tissue corrosion solution.

[0068] Add concentrated sulfuric acid to copper sulfate first, stir well, concentrated sulfuric acid can completely dissolve copper sulfate, then add hydrochloric acid. If hydrochloric acid is added to copper sulfate first, the dissolution of copper sulfate is not sufficient.

[0069] In some preferred embodiments, the forging to be tested is obtained through heat treatment, water immersion ultrasonic flaw detection and machining, and meets t...

Embodiment 1

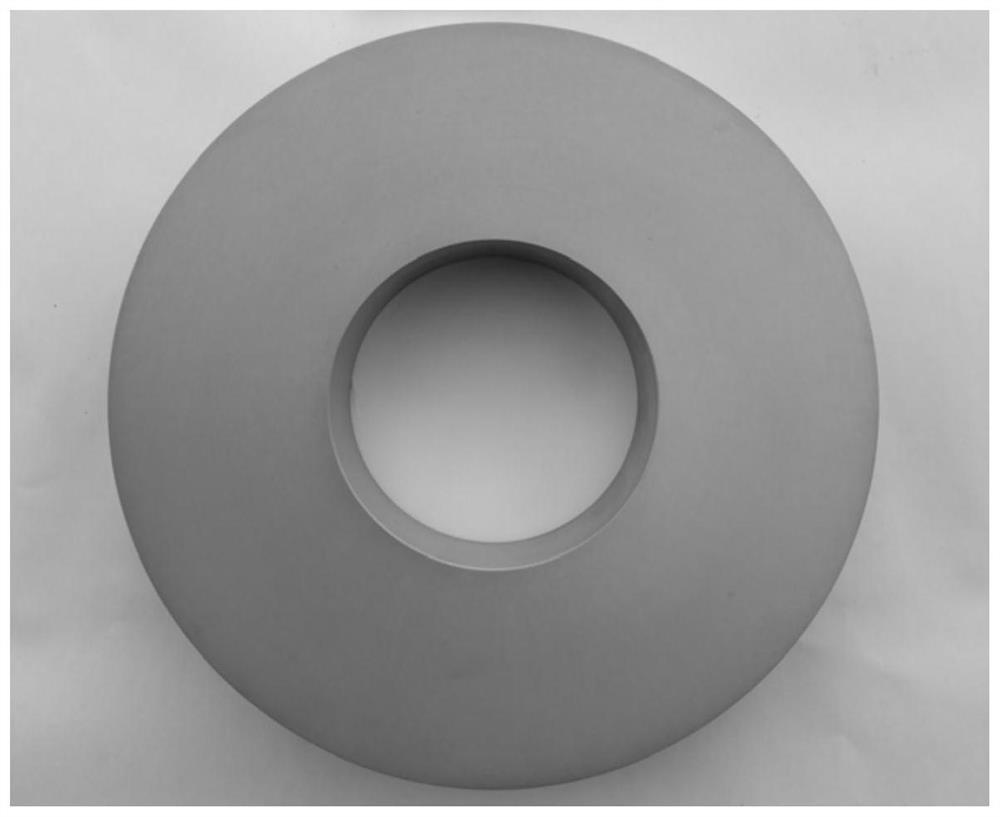

[0112] A rapid detection method for the surface structure of a GH4720Li nickel-based superalloy disk forging:

[0113] After the disc forging is subjected to standard solution + aging heat treatment, it is judged by ultrasonic flaw detection that there is no metallurgical defect inside the disc forging that affects the service performance of the material, and after the surface flaw detection layer is machined, use clean water and absolute ethanol to clean the oil on the surface of the disc forging , and placed in a fume hood, using a fan to dry. Afterwards, the outer surface of the disc forging is subjected to low-magnification microstructure corrosion.

[0114] Among them, the low-magnification structural corrosion inspection is aimed at the entire outer surface inspection of the disc forging.

[0115] The specific steps of low-magnification tissue corrosion inspection are as follows:

[0116] (1) Low-magnification tissue corrosion

[0117] The disc forging is placed in th...

Embodiment 2

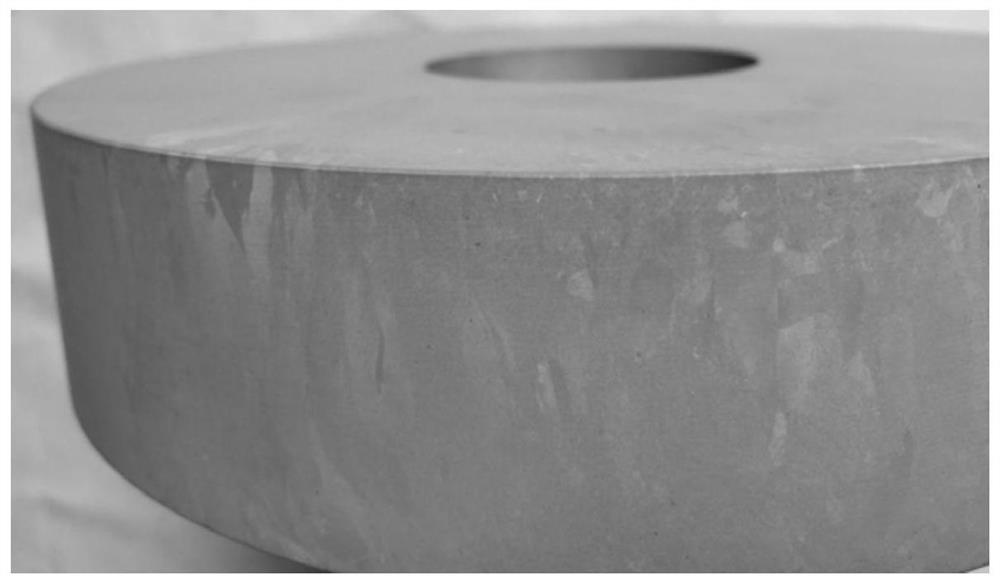

[0127] A rapid detection method for the surface structure of a GH4720Li nickel-based superalloy disk forging, the difference from Example 1 is that when the low-magnification structure is inspected in step (4), the surface structure is observed to be uneven, and the suspected coarse-grained structure is detected. Such as figure 2 , this step cannot judge that the forging of this plate is a qualified product, so it enters the high-magnification structure inspection.

[0128] The specific steps of high-magnification tissue inspection are as follows:

[0129] (1) Polishing treatment

[0130] Use sandpaper and diamond polishing fluid to polish the area where it is impossible to judge whether it is coarse grain or uneven structure after corrosion of the low-magnification structure, and then use a fan to dry it.

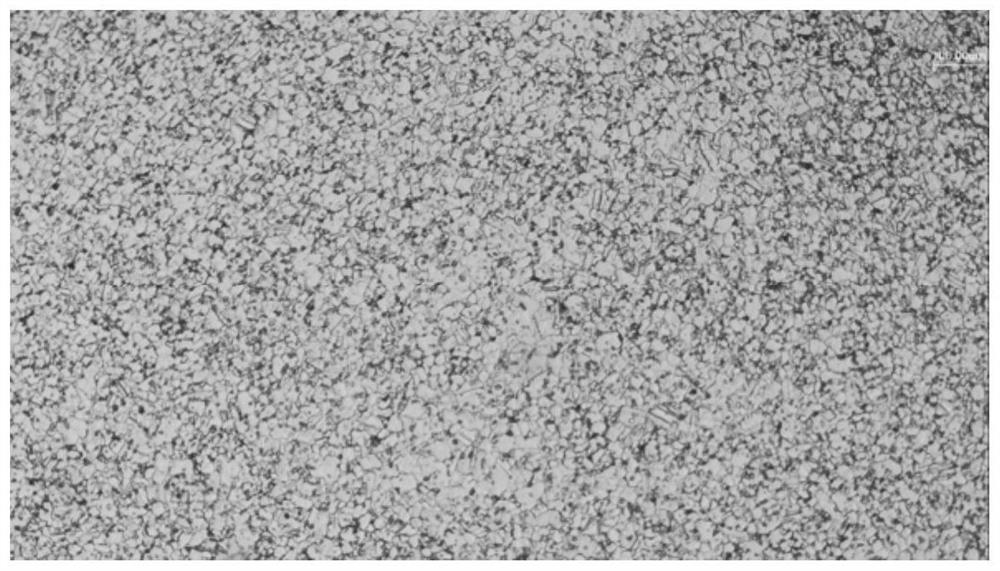

[0131] (2) High tissue corrosion

[0132] The disc forging is placed in the corrosion tank of the fume hood, the corrosion solution is applied to the local polishing a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com