Molten metal spatter fabric containing flame-retardant polyester and dyeing and finishing process of molten metal spatter fabric

A flame retardant polyester, molten metal technology, applied in the field of molten splash safety protection fabrics, can solve the problems of poor resistance to molten metal impact, tingling, and poor wearing comfort, and achieves good moisture permeability, clear lines, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

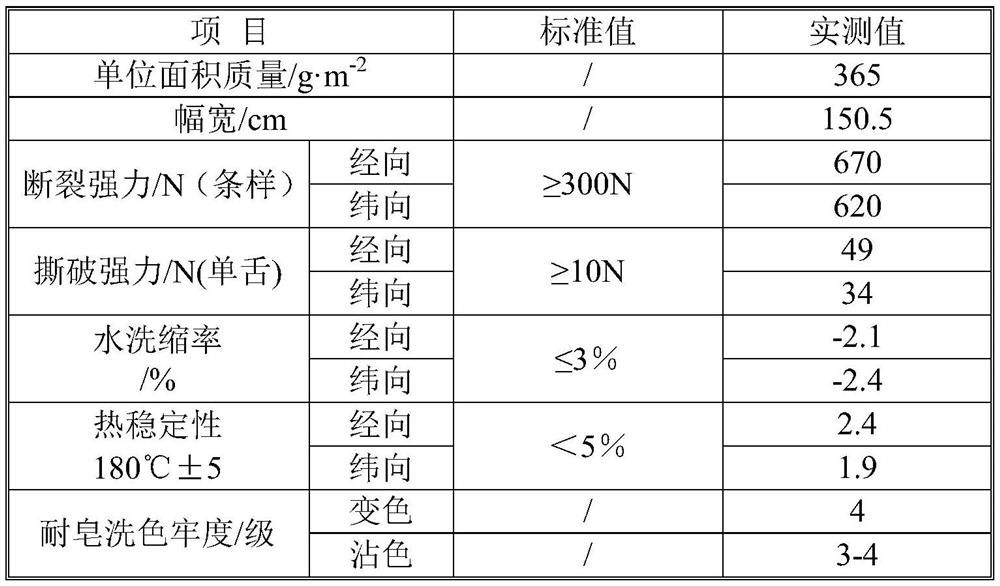

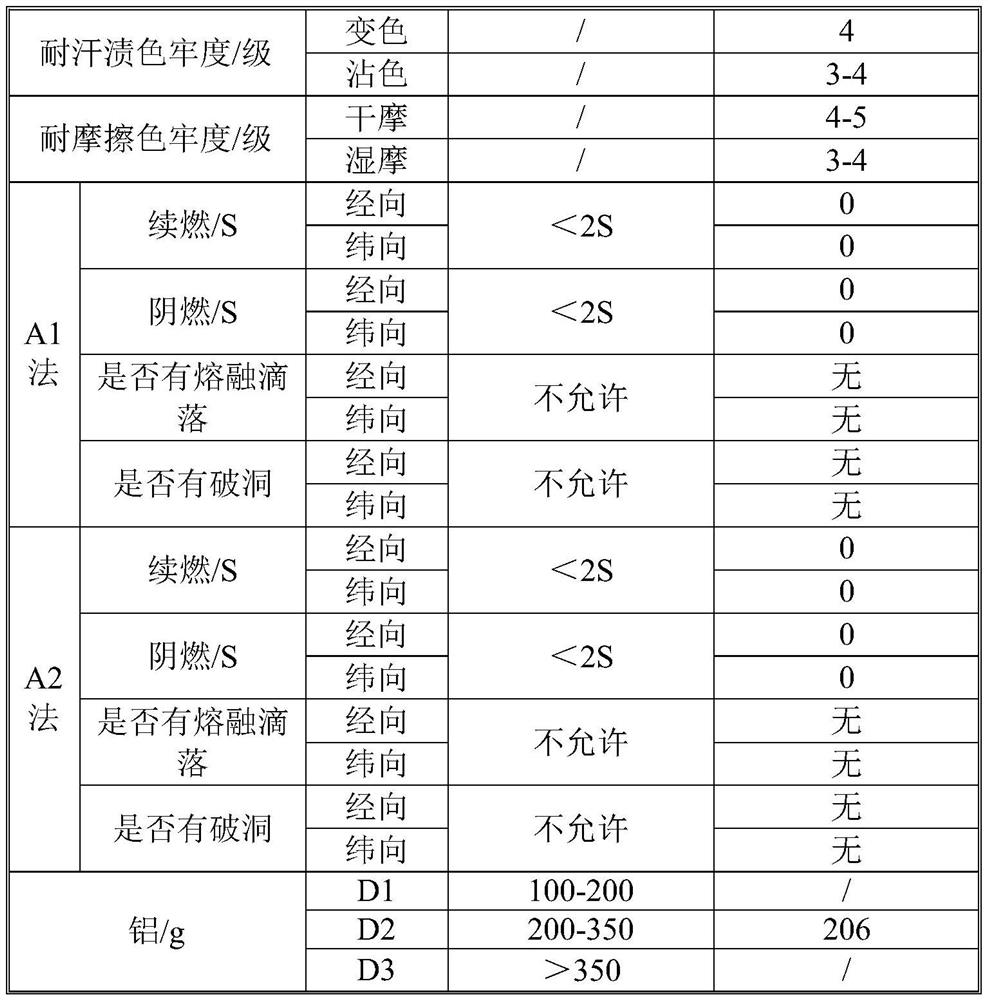

[0038] A protective fabric containing flame-retardant polyester molten metal splashes, which is made of blended flame-retardant viscose fiber and flame-retardant polyester fiber, of which flame-retardant viscose fiber accounts for 70%, and flame-retardant polyester fiber accounts for 30%. The mass is 400g / m 2 .

[0039] The dyeing and finishing process adopted for the above flame-retardant polyester molten metal splash protection fabric:

[0040] Step 1, singeing the flame-retardant polyester molten metal splash protection fabric;

[0041] Step 2, enzymatic deboiling

[0042] Perform enzymatic deboiling treatment on the fabric treated in step 1. The deboiling solution is composed of compound desizing enzyme TF-162 with a concentration of 20g / L. Padding in the cooking liquid, using two dipping and two rolling, the excess rate is 70% to 100%; then steam the molten metal splash protection fabric after padding, the steaming temperature is 100°C to 102°C, and the time is 40min ...

Embodiment 2

[0052] In this embodiment, a protective fabric containing flame-retardant polyester molten metal splashes is formed by blending flame-retardant viscose fiber and flame-retardant polyester fiber, wherein flame-retardant viscose fiber accounts for 80%, and flame-retardant polyester fiber accounts for 20%. The mass per unit area of the fabric is 350g / m 2 .

[0053] The dyeing and finishing process adopted for the above flame-retardant polyester molten metal splash protection fabric:

[0054] Step 1, singeing the flame-retardant polyester molten metal splash protection fabric;

[0055] Step 2, enzymatic deboiling

[0056] The fabric treated in step 1 is subjected to enzymatic deboiling treatment, and the deboiling solution is composed of composite desizing TF-162 with a concentration of 15g / L. The descaling process is specifically as follows: firstly, the fabric treated in step 1 is dipped in the descaling solution, and the excess rate is 70% to 100% by using two dippings and...

Embodiment 3

[0067] In this embodiment, a protective fabric containing flame-retardant polyester molten metal splash is formed by blending flame-retardant viscose fiber and flame-retardant polyester fiber, wherein flame-retardant viscose fiber accounts for 90%, and flame-retardant polyester fiber accounts for 10%. , the mass per unit area of the fabric is 380g / m 2 .

[0068] The dyeing and finishing process adopted for the above flame-retardant polyester molten metal splash protection fabric:

[0069] Step 1, singeing the flame-retardant polyester molten metal splash protection fabric;

[0070] Step 2, enzymatic deboiling

[0071] The fabric treated in step 1 is subjected to enzymatic deboiling treatment, and the deboiling liquid is composed of composite desizing enzyme TF-162, and the concentration is 10 g / L. The descaling process is specifically as follows: firstly, the fabric treated in step 1 is dipped in the descaling solution, and the excess rate is 70% to 100% by using two dipp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com