Oil injection method

A technology of fuel injection volume and single injection, applied in fuel injection control, engine control, machine/engine, etc., can solve the problems of difficult engine cold start, unfavorable oil film evaporation on the cylinder liner, and inability to control temperature, so as to improve engine oil Effects of Dilution and Oil Rise Problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

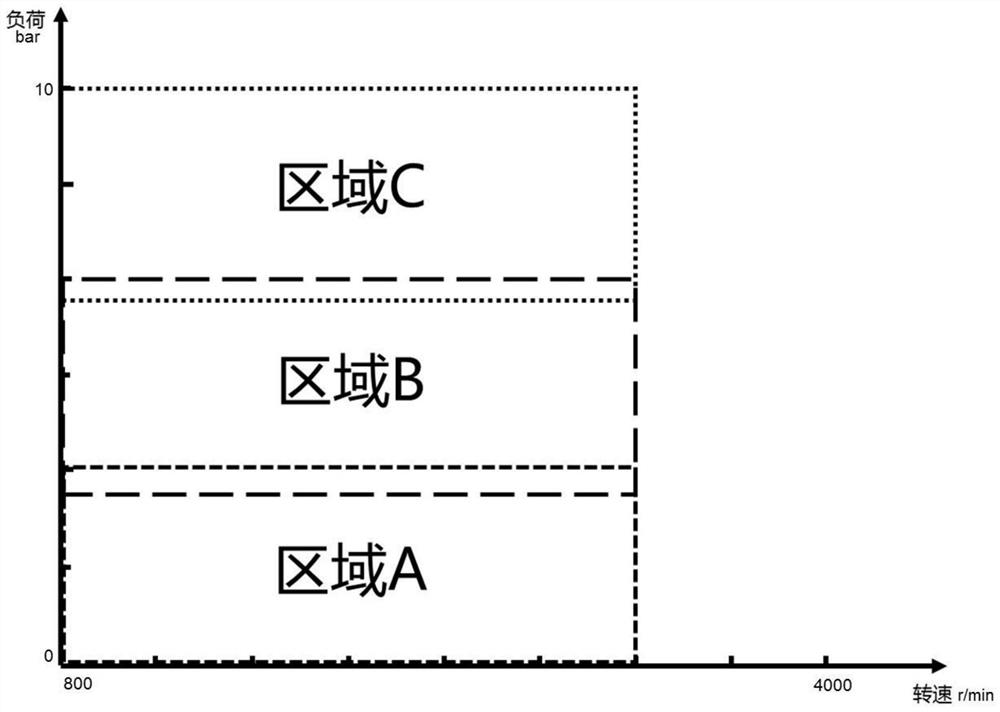

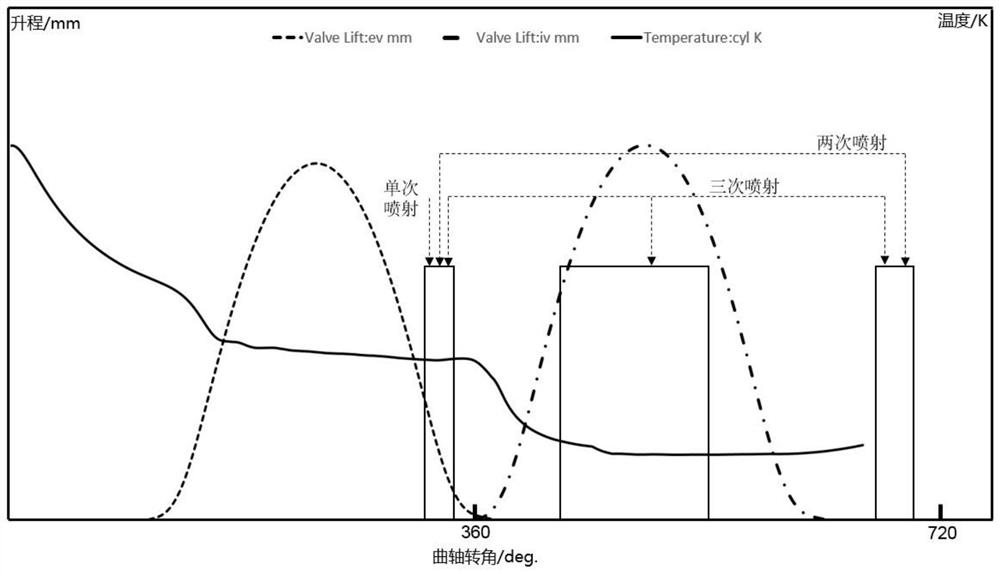

[0019] Such as figure 1 and figure 2 As shown, the present invention proposes a fuel injection method for alleviating the problem of rising oil level of supercharged direct injection engine under extremely cold conditions, specifically as follows:

[0020] Such as figure 1 As shown, when the working condition of the engine is in region A, the engine is running in the low-load region, the temperature of the fuel tank under extremely cold conditions (-30°C) is basically the same as the ambient temperature, and the fuel supply system has little effect on heating the fuel , causing the temperature of the oil beam entering the combustion chamber to be close to the ambient temperature, and when the engine is in this area, the fuel temperature is lower, so when the engine works in the range of area A, a single injection is performed in each working cycle, and at the exhaust top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com