A dual temperature control cooling system and control method thereof, and dual temperature control cooling machine

A cooling system and dual temperature control technology, applied in the direction of refrigerators, compressors, manufacturing tools, etc., can solve the problems of insufficient energy saving, complex water channels of dual temperature control coolers, etc., and achieve energy saving, streamlined water channels, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The present invention avoids the traditional water-water heat exchange and electric heating mode, and directly realizes the heating of low-temperature cooling water by adding a heat exchanger (such as a finned heat exchanger) sharing the condensing fan with the condenser, Meet the temperature control requirements of high temperature water. It realizes waste heat utilization and simplifies the waterway system, reducing components such as waterway heat exchangers, water pumps and electric heating.

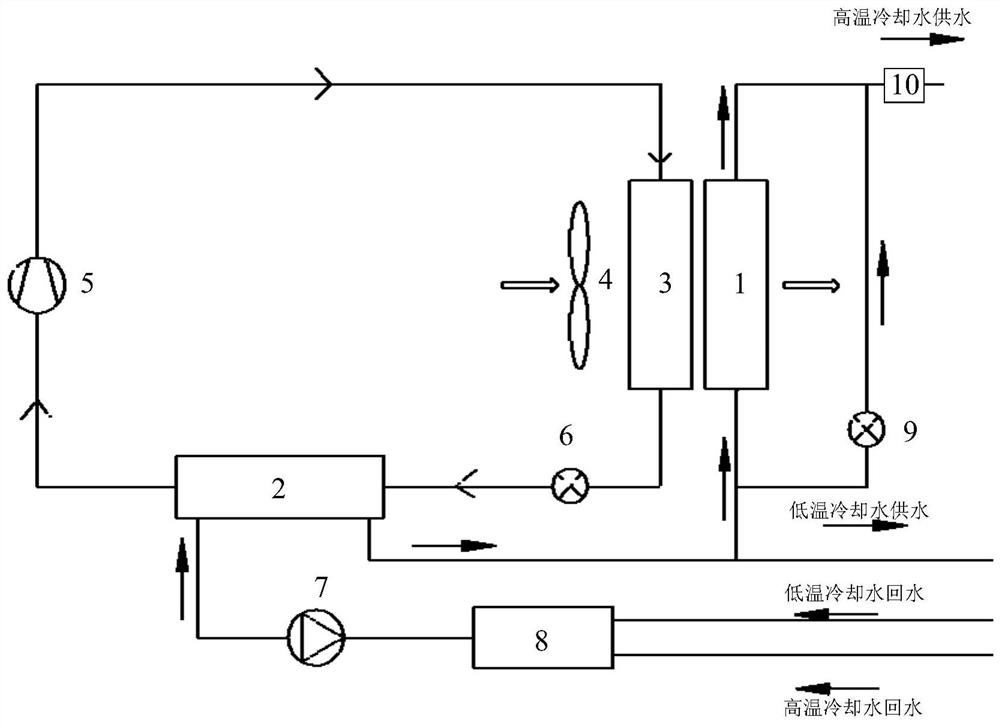

[0030] figure 1 It is a schematic structural diagram of a dual-temperature control cooling system according to an embodiment of the present invention, such as figure 1 As shown, the dual temperature control cooling system includes:

[0031] The heat exchanger 1 is arranged on the high-temperature cooling water supply branch led by the low-temperature cooling water supply circuit of the evaporator 2, and is used to heat the low-temperature cooling water flowing out of the eva...

Embodiment 2

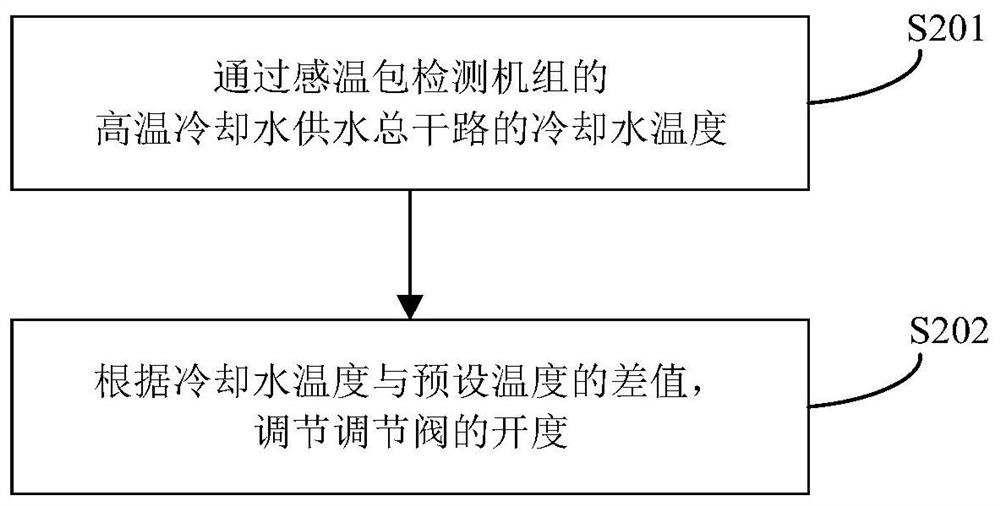

[0046] figure 2 It is a flow chart of a control method of a dual temperature control cooling system according to an embodiment of the present invention, such as figure 2 As shown, the method includes the following steps:

[0047] Step S201, detecting the cooling water temperature of the high-temperature cooling water supply trunk road of the unit through the temperature sensing package;

[0048] Step S202, adjusting the opening degree of the regulating valve according to the difference between the temperature of the cooling water and the preset temperature.

[0049] In this embodiment, the newly added fin heat exchanger is used to heat up the low-temperature cooling water, and at the same time, the temperature of the water is tested according to the temperature sensing package, and then the flow rate of the low-temperature cooling water is controlled by the regulating valve, so as to realize the precise temperature control of the high-temperature cooling water .

[0050] ...

Embodiment 3

[0054] This embodiment provides an electronic device, which is used in a method for controlling a dual-temperature control cooling system. The electronic device includes: at least one processor; and a memory communicatively connected to the at least one processor; wherein,

[0055] The memory stores instructions that can be executed by the one processor, and the instructions are executed by the at least one processor, so that the at least one processor can: detect the high-temperature cooling water supply mains of the unit through the temperature sensing package The cooling water temperature of the main road; adjust the opening of the regulating valve according to the difference between the cooling water temperature and the preset temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com