Preparation method of porous TiO2/NaPSS composite sensitive material and product thereof

A technology for compounding sensitive, polystyrene microspheres, applied in the field of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

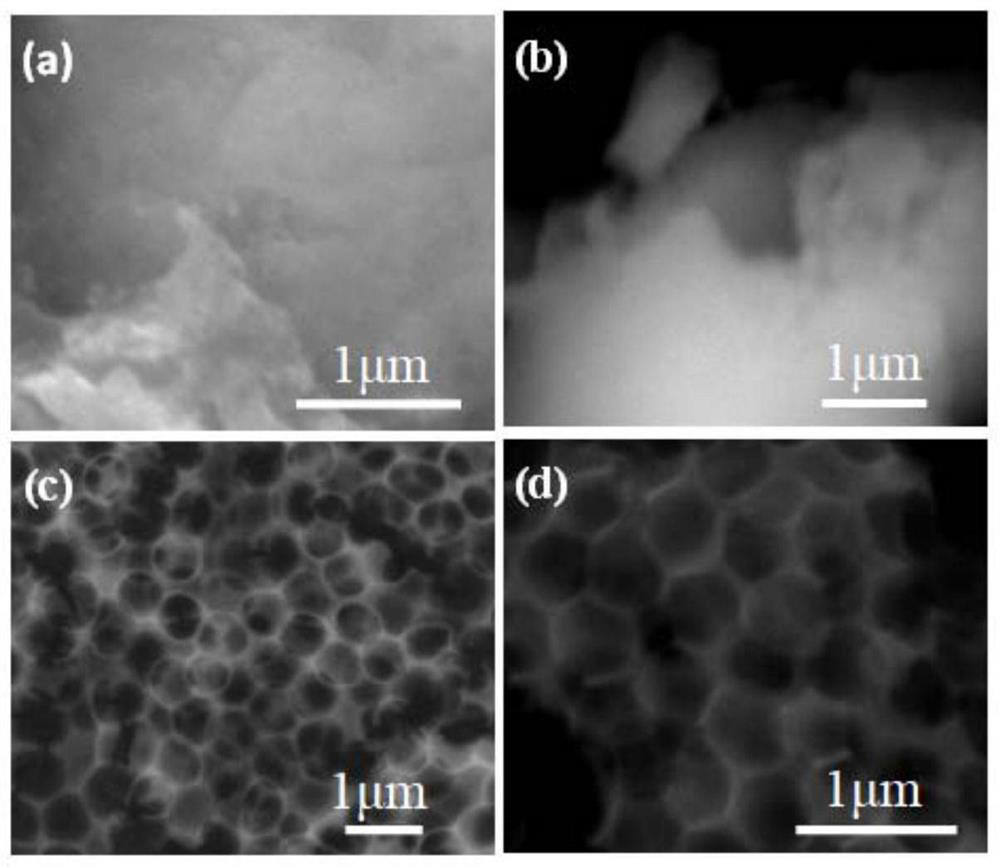

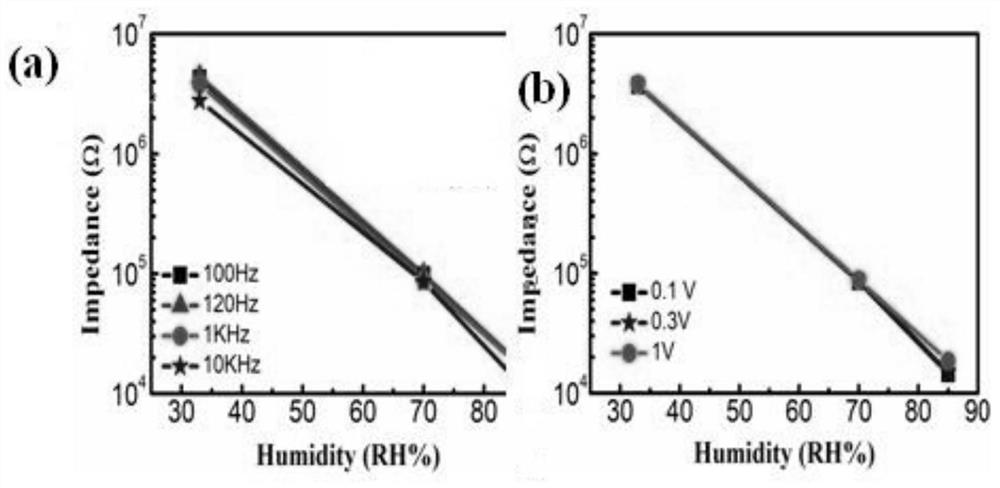

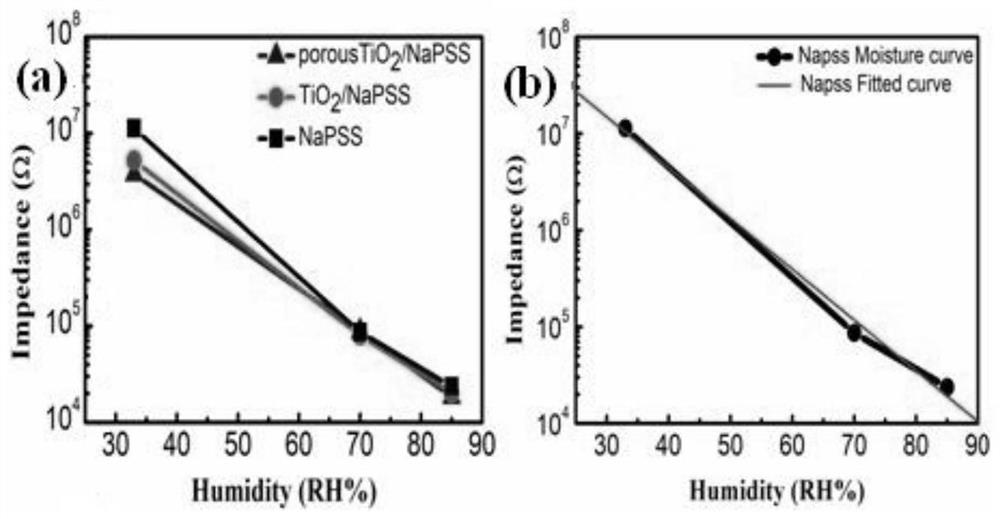

[0025] Embodiment 1, porous TiO 2 Preparation of composite sensitive materials of NaPSS

[0026] In this experiment, porous TiO was prepared by template method combined with spin coating method. 2 / NaPSS composite sensitive material, the specific steps are as follows: firstly, the interdigitated electrode is ultrasonically cleaned with absolute ethanol and acetone, and 1000nm polystyrene microspheres and 0.3mol / L titanium tetrachloride aqueous solution are evenly coated on the surface by spin coating method. On the interdigitated electrode substrate, dry it at 100°C for 1 hour; then put the sample into a dichloromethane solution and sonicate it for 2-10 minutes to dissolve the polystyrene microspheres in the sample, and drive the solution at a constant temperature of 200°C for 1 hour. Porous TiO 2 membrane; then prepare an aqueous solution of sodium polystyrene sulfonate with a mass fraction of 1%, and appropriately add sodium carboxymethyl cellulose to improve the viscosity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com