A preparation method of iron manganese oxide/starch/biochar composite material for simultaneously adsorbing inorganic arsenic and organic arsenic in water

A technology of iron-manganese oxide and composite materials, which is applied in the field of functional materials for environmental pollutants, can solve problems such as easy aggregation, lower specific surface area, and influence on arsenic adsorption capacity, and achieve easy recycling, low cost, and reduced aggregation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

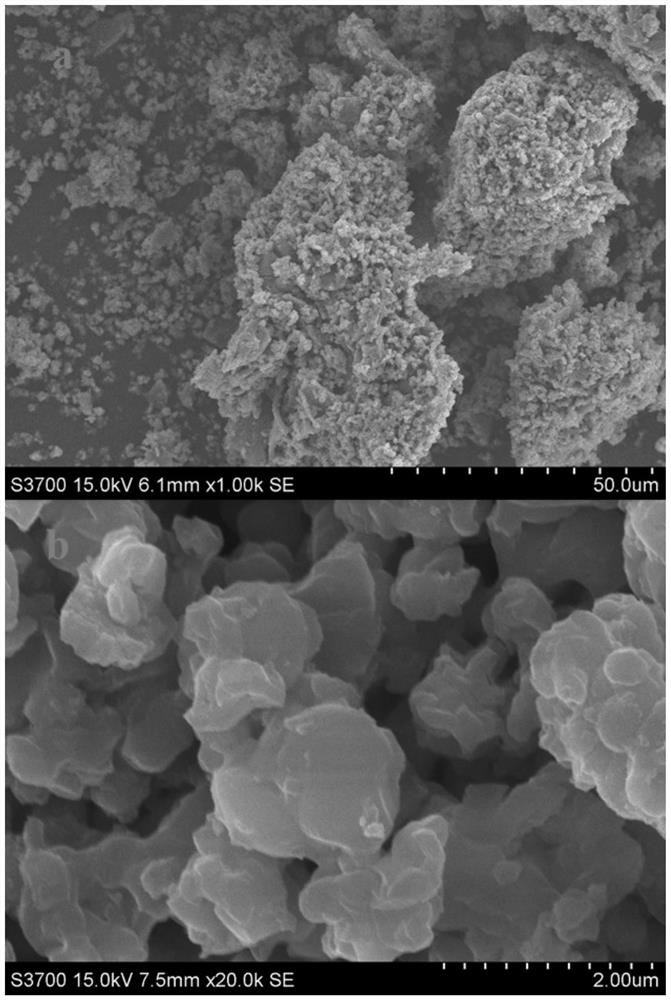

[0029] The preparation of iron-manganese oxide / starch / biochar composite material includes the following steps:

[0030] (1) Air-dry the corn stalks, crush them with a pulverizer, calcine them in a tube furnace at 500 °C under nitrogen protection for 1.5 h, and set the heating program to 5 °C / min, and then grind them through a 0.15 mm sieve to prepare corn stalk biomaterials. Carbon (specific surface area of 137.8m 2 ·g -1 )spare.

[0031] (2) Weigh 0.187g corn starch and 0.933g corn stalk biochar into 10mL deionized water and mix thoroughly to prepare a mixed stabilizer solution of corn starch and biochar; weigh 5.57g FeSO 4 ·7H 2 O and 0.302g MnSO 4 , dissolved in 30 mL of deionized water to prepare FeSO 4 and MnSO 4 Mixed solution; weigh 1.264g KMnO 4 , dissolved in 25 mL of deionized water to prepare KMnO 4 solution;

[0032] (3) Add 10 mL of corn starch and biochar mixed stabilizer solution to 30 mL of FeSO 4 and MnSO 4 In the mixed solution, stir magnetically...

Embodiment 2

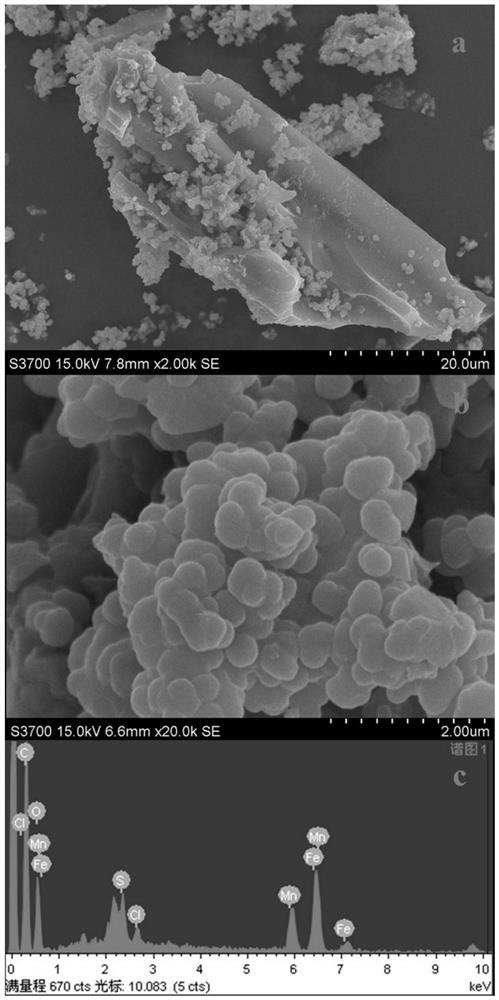

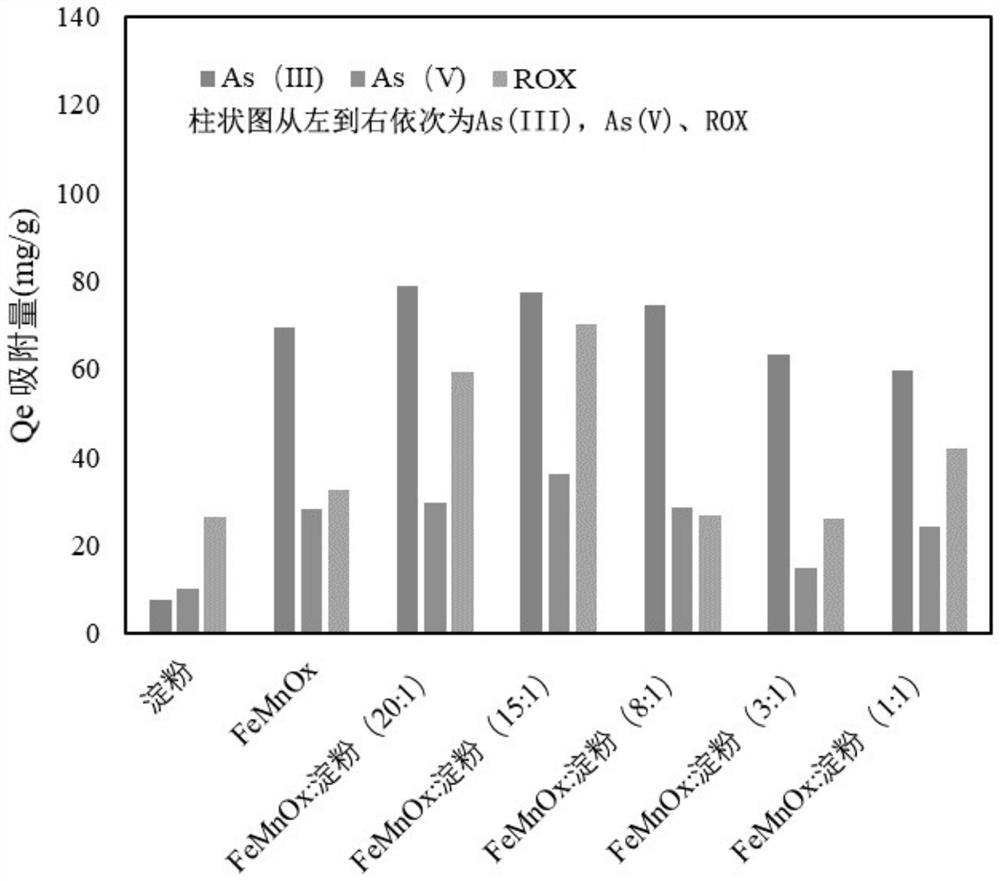

[0035]1. Referring to the preparation steps of Example 1, the amount of corn stalk biochar is set to 0, and the amount of corn starch is set to 0.14g, 0.187g, 0.35g, 0.933g, 2.8g, respectively, and then prepare iron and manganese oxidation The prepared iron-manganese oxide / starch composite material has a mass ratio of iron-manganese oxide and starch of 20:1, 15:1, 8:1, 3:1 and 1:1. Taking iron manganese oxide / starch composite material (iron manganese oxide: starch mass ratio=20:1) as an example, the specific preparation steps are:

[0036] (1) Weigh 0.14g of cornstarch and add it to 10mL of deionized water and mix thoroughly to prepare a cornstarch solution; weigh 5.57g of FeSO 4 ·7H 2 O and 0.302g MnSO 4 , dissolved in 30 mL of deionized water to prepare FeSO 4 and MnSO 4 Mixed solution; weigh 1.264g KMnO 4 , dissolved in 25 mL of deionized water to prepare KMnO 4 solution;

[0037] (2) Add 10 mL of cornstarch solution to 30 mL of FeSO 4 and MnSO 4 In the mixed solut...

Embodiment 3

[0047] The purpose of this example is to study the adsorption mechanism of iron-manganese oxide / starch / biochar composites to As(III), As(V) and ROX, and the specific steps are as follows:

[0048] Take the iron-manganese oxide / starch / biochar composite material (the mass ratio of iron-manganese oxide: starch: biochar is 15:1:5) prepared in the above example to As(III), As(V) and ROX adsorption. Prepare 100 ppm As(III), As(V) and ROX solutions respectively, adjust the pH to 5.5 with NaOH or HCl, and put 0.15 g of iron-manganese oxide / starch / biochar composite into 500 mL of 100 ppm As(III), respectively , As(V) and ROX solution, continuously stirred with a magnetic stirrer (750 rpm) for 24 h, filtered with suction, frozen and then lyophilized.

[0049] For starch (Starch), biochar (BC), iron manganese oxide (FeMnO) X ), and FeMnO / starch / biochar composites (FeMnO) before and after adsorption X -starch-BC) for infrared spectroscopic analysis, the results are as follows Figure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com