Preparation and application of covalent organic framework porous nano composite material

A technology of covalent organic framework and nanocomposite material, applied in other chemical processes, chemical instruments and methods, water/sludge/sewage treatment, etc., to achieve the effect of cost saving, simple process and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

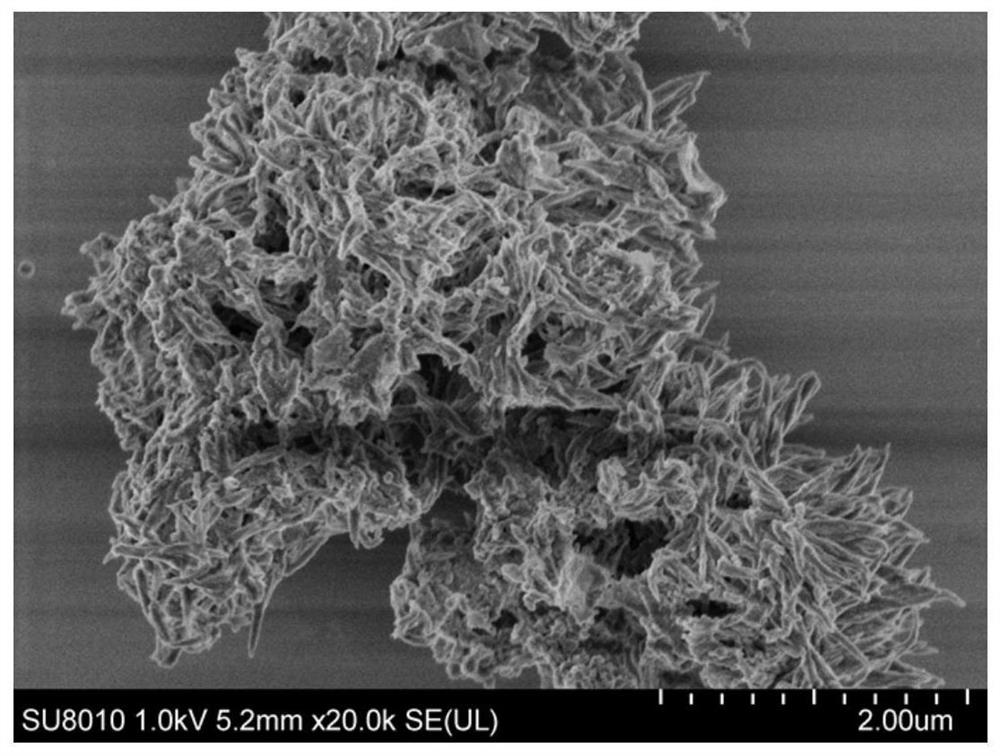

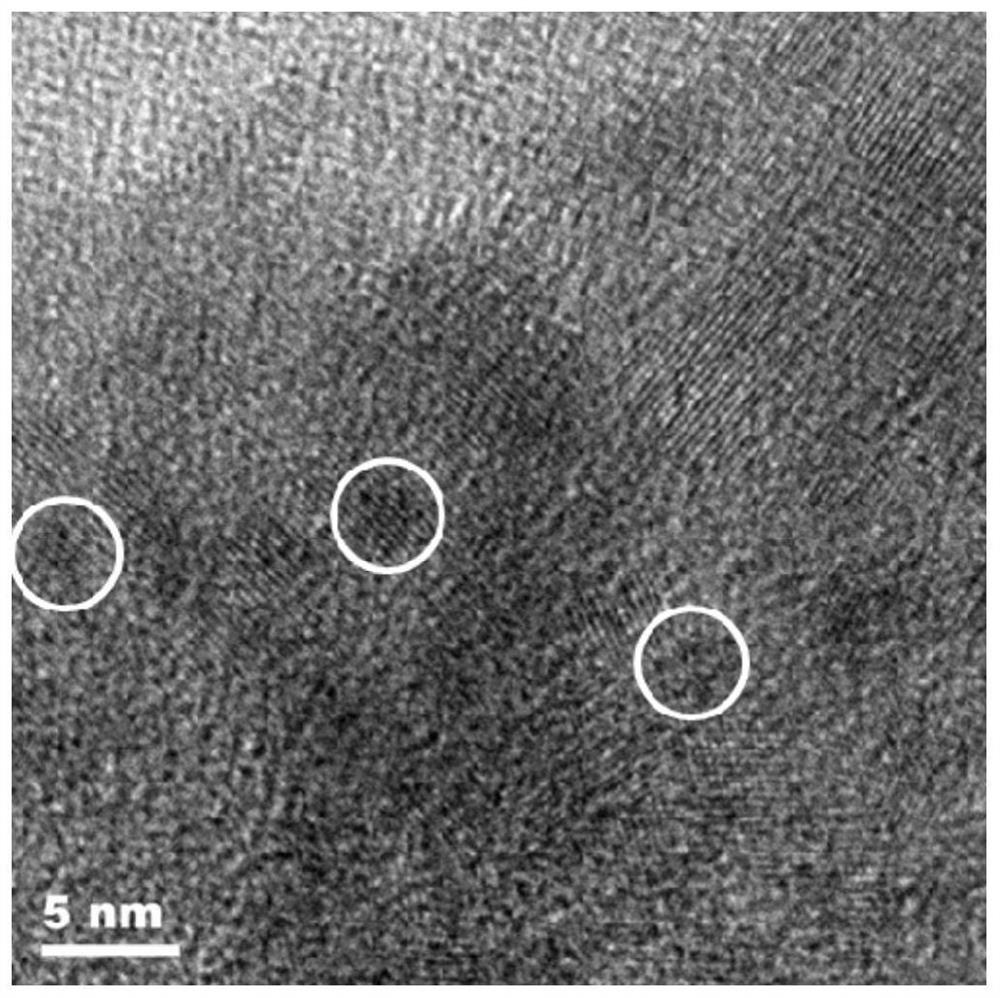

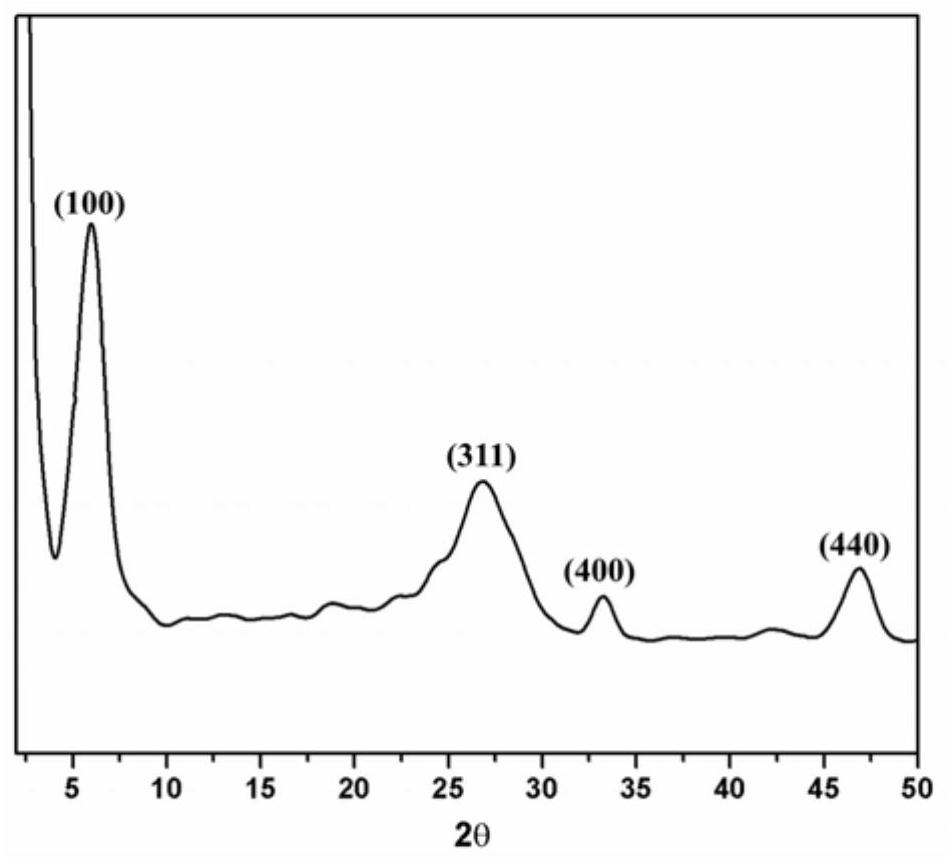

[0025] In 2 S 3 Nanoparticle-supported covalent organic framework composites (In 2 S 3 Preparation of @COF) nanocomposites

[0026] Preparation of covalent organic framework (COF-TpBD): Add 2,4,6-trialdehyde phloroglucinol (315.21 mg, 1.5 mmol), benzidine (414.54 mg, 2.25 mmol) to a 50 mL pyrex tube ), mesitylene (5 mL), 1,4-dioxane (5 mL) and aqueous acetic acid (1.5 mL, 6M), the mixture was sonicated (100% power) for 20 min by three freeze-pump-thaw cycles Degassed, sealed under vacuum, and heated at 120 °C for 3 days, after taking out, the reaction mixture was cooled to room temperature, and the yellow precipitate was collected by centrifugation, washed with ethanol, tetrahydrofuran, and N,N-dimethylformamide for several times, and then vacuum-dried at 60°C for 12 hours to obtain a covalent organic framework (COF-TpBD);

[0027] In 2 S 3 @covalent organic framework (In 2 S 3 @COF) preparation: COF-TpBD (200 mg) was dispersed in anhydrous n-hexane (40 mL) and sonica...

Embodiment 2

[0034] In 2 S 3 @COF Porous Nanocomposites for Hg in Water 2+ remove

[0035] (1) pH and In 2 S 3 Optimization of @COF usage

[0036] pH value of aqueous solution and In 2 S 3 The dosage of @COF porous nanocomposite was optimized. The results showed that in the range of pH3-8, In 2 S 3 @COF on Hg 2+ It has a high adsorption efficiency, which also shows that the porous material itself and loaded with nanoparticles have good stability. Therefore, the pH value of the aqueous solution was selected as the experimental reaction pH value of 7. When In 2 S 3 When the dosage of @COF increased from 1mg / 30mL to 5mg / 30mL, In 2 S 3 @COF on Hg 2+ The adsorption rate increases sharply, which is due to the increase in the surface area of the material and the increase in the number of active adsorption sites on the nanoparticles. When In 2 S 3 When the dosage of @COF continued to increase from 5mg / 30mL to 8mg / 30mL, In 2 S 3 @COF on Hg 2+ The adsorption rate is almost unc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com