Machining die and machining method for high-strength titanium alloy pipe blank

A technology for processing molds and processing methods, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of poor material forming performance, large deformation resistance, serious springback, etc., and achieve high forming accuracy, low cost, and easy operation. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

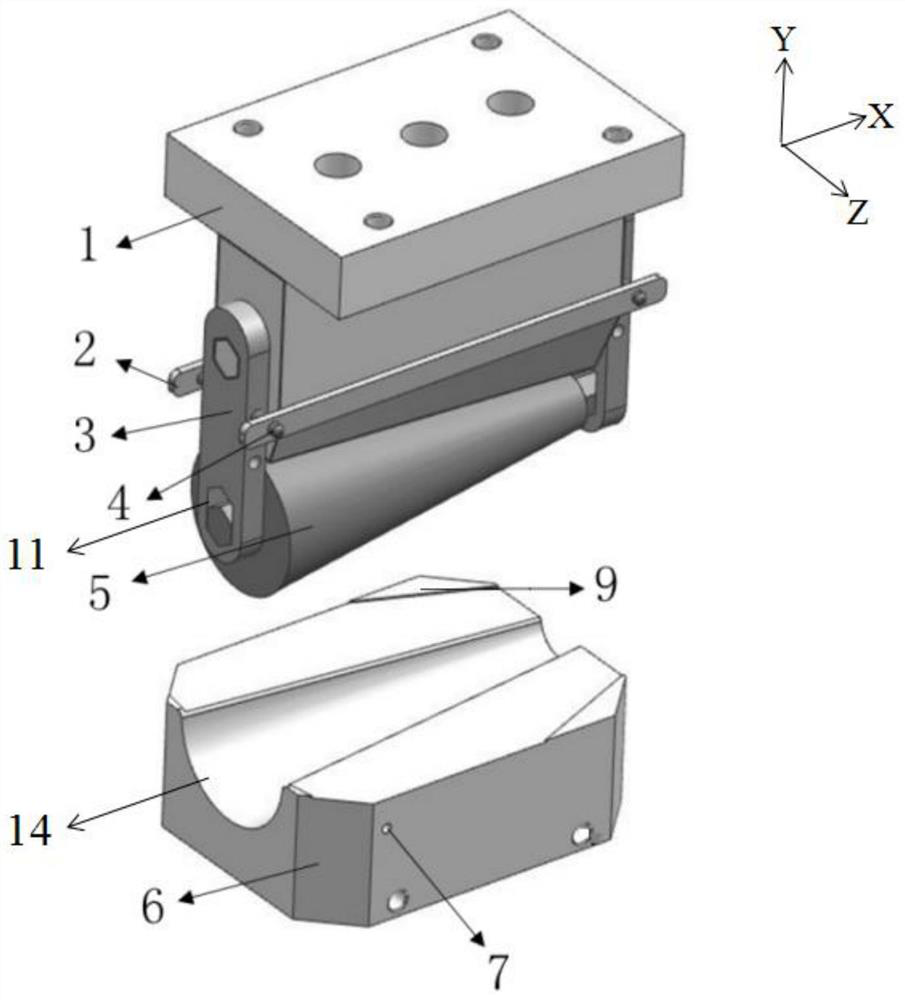

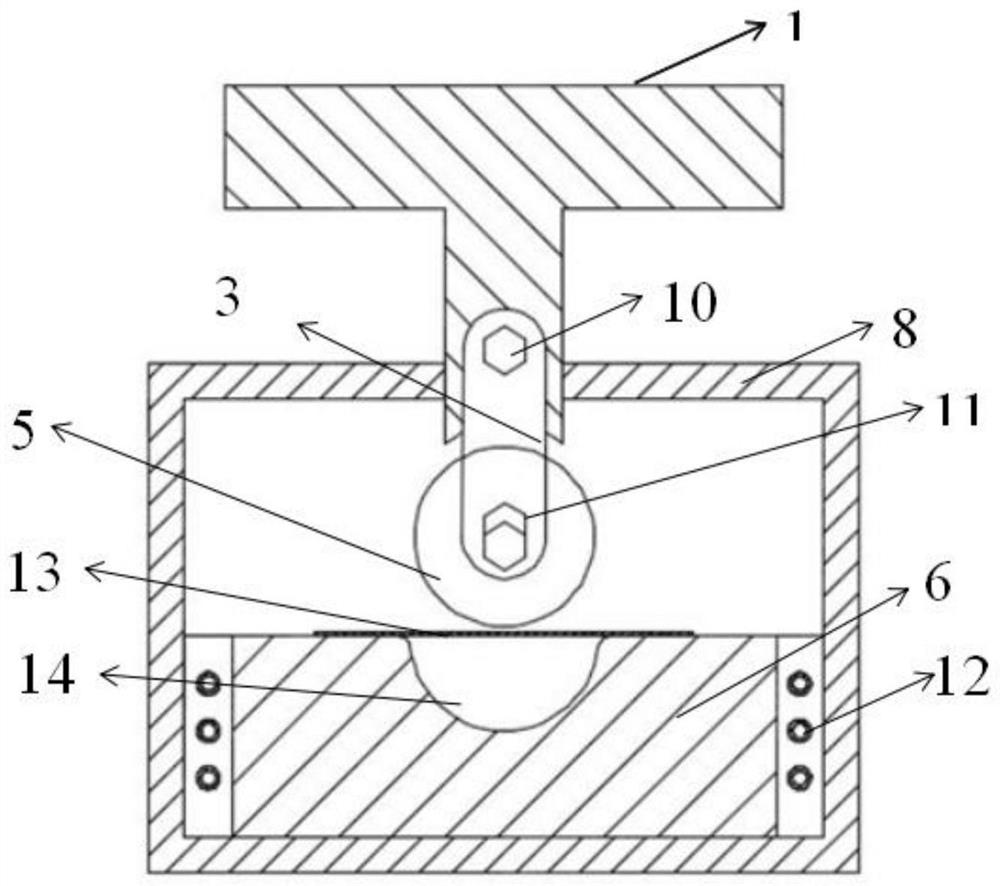

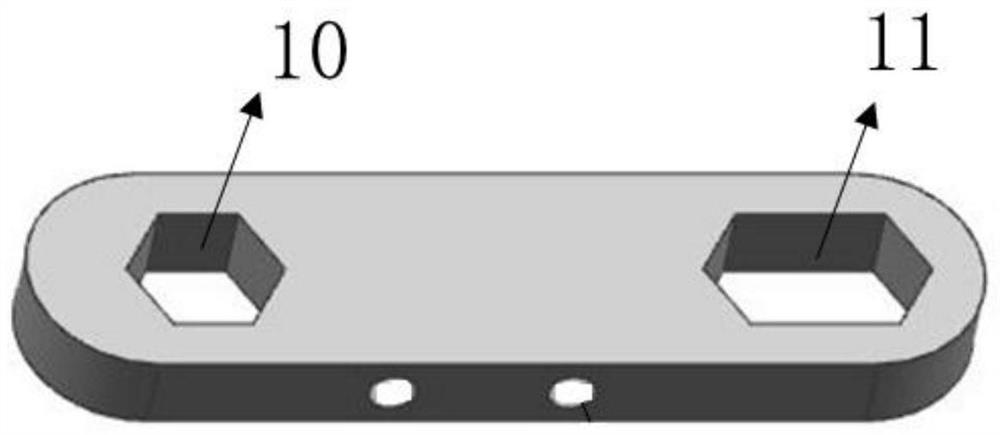

[0068] Such as Figure 5-6 As shown, the embodiment of the present invention provides a method for processing a high-strength titanium alloy conical tube blank, comprising the following steps:

[0069] Step S0, expand according to the diameter of the neutral layer of the tapered tube billet, cut out the fan-shaped Ti55 high-strength titanium alloy sheet 13, and grind a 15° bevel on the straight edge section, such as Figure 5shown. Boron nitride lubricant is sprayed on the surface of the Ti55 high-strength titanium alloy sheet material 13, the shaping cavity 14 and the third module 5, on the one hand to ensure that the Ti55 high-strength titanium alloy sheet material 13, the shaping cavity 14 and the The friction force of the third module 5 is small, and on the other hand, it prevents oxidation of the Ti55 high-strength titanium alloy sheet 13 under high temperature.

[0070] Step S1, after heating the second module 6 to 750°C through the induction coil, place the Ti55 high-...

Embodiment 2

[0075] An embodiment of the present invention provides a method for processing a high-strength titanium alloy round tube blank, comprising the following steps:

[0076] In step S0, unfold according to the diameter of the neutral layer of the circular tube billet, cut out a rectangular TC4 high-strength titanium alloy sheet 13, and grind a 15° bevel on the straight edge section. Boron nitride lubricant is sprayed on the surface of TC4 high-strength titanium alloy sheet material 13, the shaping cavity 14 and the third module 5, on the one hand to ensure that the TC4 high-strength titanium alloy sheet material 13, shaping cavity 14 and The frictional force of the third module 5 is small, and on the other hand, it prevents the oxidation of the TC4 high-strength titanium alloy sheet 13 under high temperature;

[0077] Step S1, after heating the second module 6 to 700°C through the induction coil, place the TC4 high-strength titanium alloy sheet 13 between the two limiting bosses 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com