Objective table of laser cutting equipment

A technology of laser cutting and stage, which is applied in the direction of laser welding equipment, welding/cutting auxiliary equipment, welding equipment, etc., can solve the problem that the processing equipment is difficult to meet high flatness, so as to meet the needs of laser processing and camera detection, and meet the Automated production requirements to ensure the effect of calibration capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

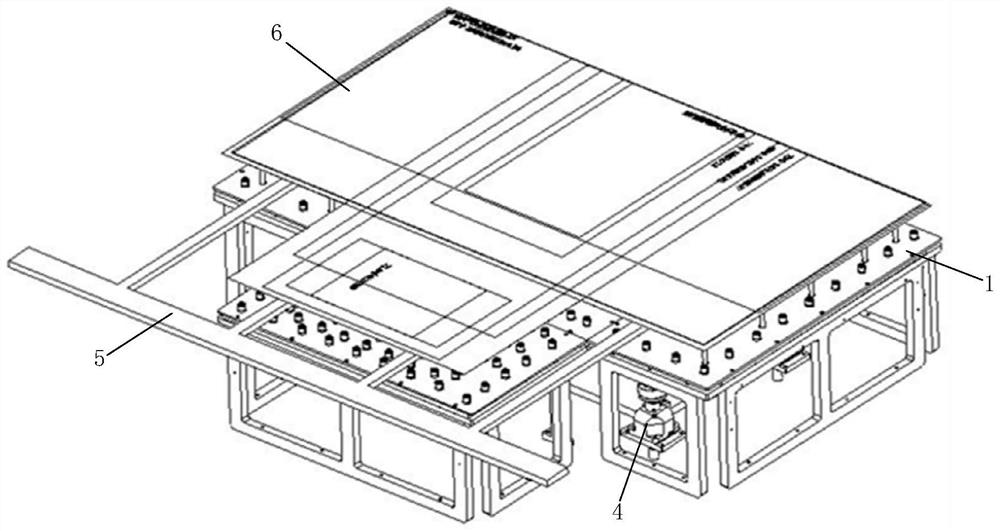

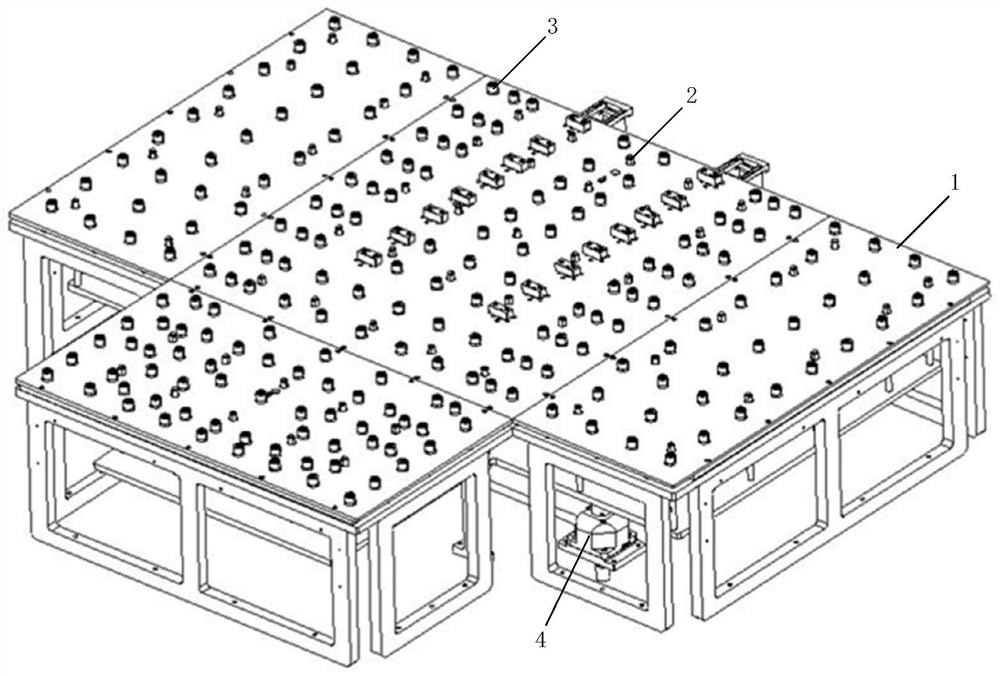

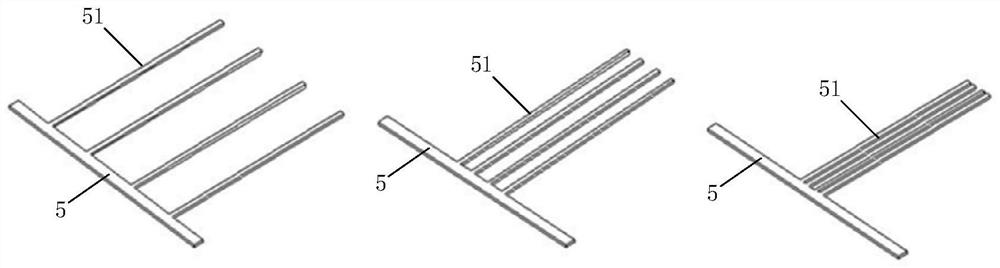

[0033] The invention relates to an object stage of laser cutting equipment, which is applied to the cutting processing of liquid crystal panels or other panels. Such as figure 1 and figure 2 As shown, the stage of the laser cutting equipment includes a support plate 1, a material receiving mechanism 2, an adsorption positioning mechanism 3 and a driving mechanism 4; the adsorption positioning mechanism 3 is arranged on the support plate 1, and the adsorption positioning mechanism 3 Adsorbing the product 6 and positioning the product 6 on the horizontal plane, the material receiving mechanism 2 is connected with the driving mechanism 4 and used to carry the product 6, and the driving mechanism 4 drives the material receiving mechanism 2 to move vertically, The product 6 carried on the receiving mechanism 2 is placed on the adsorption positioning mechanism 3 or the product 6 on the adsorption positioning mechanism 3 is separated from the adsorption positioning mechanism 3 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com