Laser butt welding device and method for transparent plastic

A technology of transparent plastic and transparent plastic plate, applied in the field of plastic laser welding and laser butt welding of transparent plastic, to achieve the effect of beautiful welding seam, high welding efficiency and high welding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

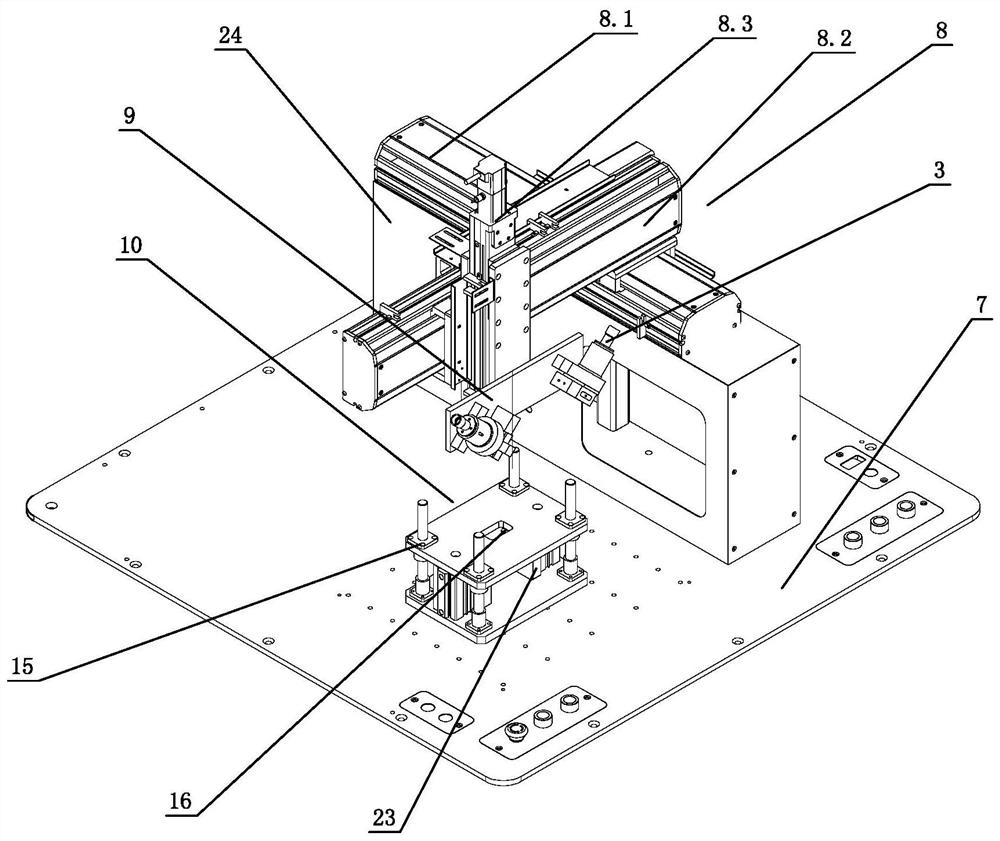

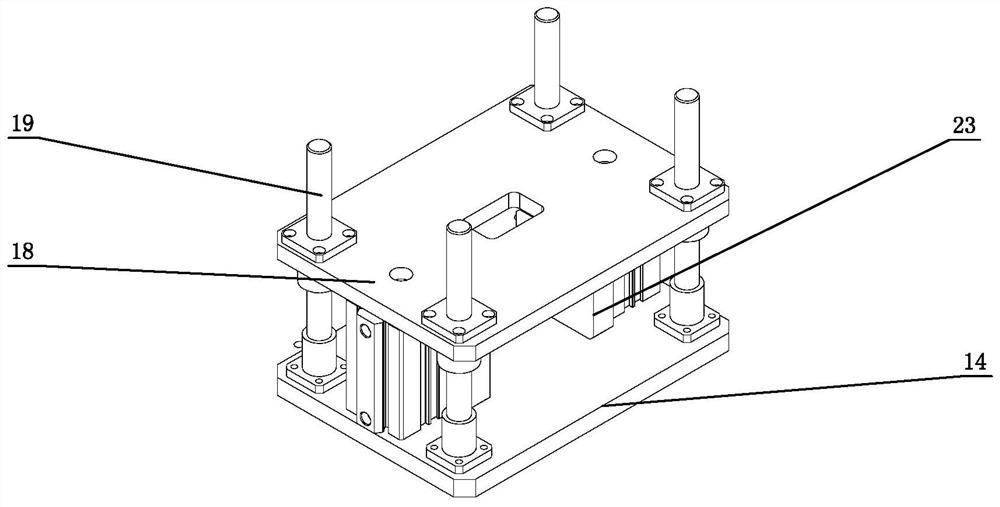

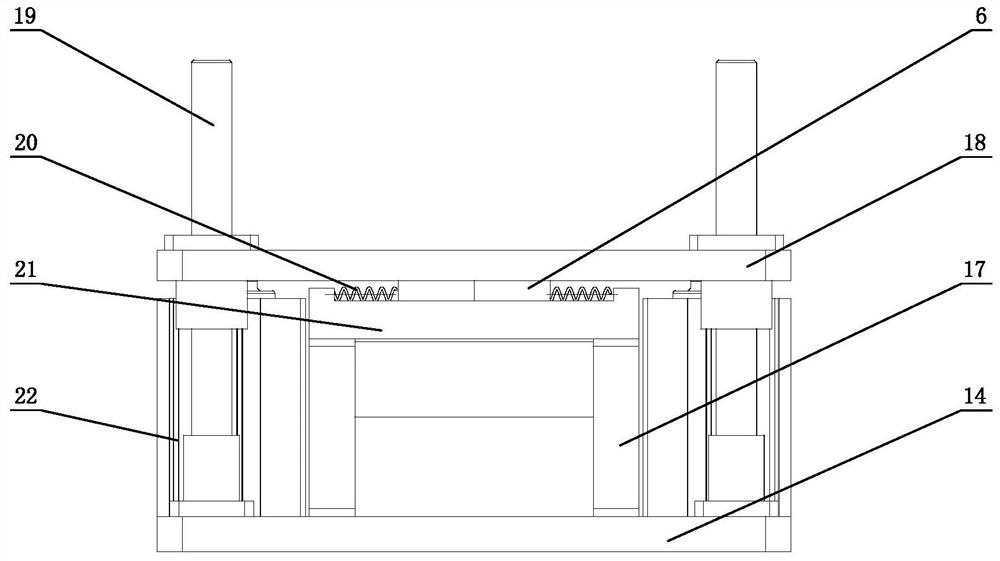

[0035] see figure 1 , a laser butt welding device for transparent plastics, comprising a laser 1 and a workbench 7, a motion platform 8 is provided on the workbench 7, and a fixture assembly 10 for clamping two butt-welded transparent plastic plates 6, two A heat sink 5 is arranged above the butt-welding transparent plastic plate 6, and the heat-radiating fin 5 covers at least the butt joint parts of two butt-welding transparent plastic plates 6, and the motion platform 8 is provided with a welding head assembly 9, which includes two welding heads 3 , the two welding heads 3 are connected to the laser 1 through the optical fiber 2, the laser beam emitted by the laser 1 is transmitted through the optical fiber 2 and passes through the two welding heads 3 respectively, and there is an angle A between the two welding heads 3, so that the laser beam passing through the two The relative angles of the two laser beams of each welding head 3 are 60° to 90°, and the focal points of the...

no. 2 example

[0061] A transparent plastic laser butt welding device is different from the first embodiment in that: more than one cylinder is provided on the supporting plate 21, and an elastic member 20 is arranged on the piston rod of the cylinder. The material of the elastic member 20 is rubber, and the cylinder’s The piston rod drives the elastic member 20 to move toward the outside of the transparent plastic plate 6, and the transparent plastic plate 6 and the elastic member 20 are in contact with each other to achieve a pressing effect.

[0062] Other parts not described are the same as those of the first embodiment, and will not be described in detail here.

no. 3 example

[0064] A transparent plastic laser butt welding device differs from the first embodiment in that the motion platform 8 is a multi-joint manipulator motion platform, the multi-joint manipulator motion platform includes a six-axis manipulator, and the six-axis manipulator is provided with a fixed welding head 3. The fixture, the six-axis manipulator drives the welding head 3 to move through the fixture; the actuator that makes the two welding heads 3 respectively pass through the motion platform 8 to realize the three-dimensional space curved welding trajectory is the actuator that realizes the three-dimensional space welding trajectory.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com