Compression molding method of household garbage

A technology of compression molding of household garbage, applied in the direction of presses, removal of solid waste, manufacturing tools, etc., can solve the problems of inconvenient operation and use, reduce the smell of household garbage, reduce labor intensity, etc., and achieve smooth and smooth hammer action , better compression effect, and improved compression efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

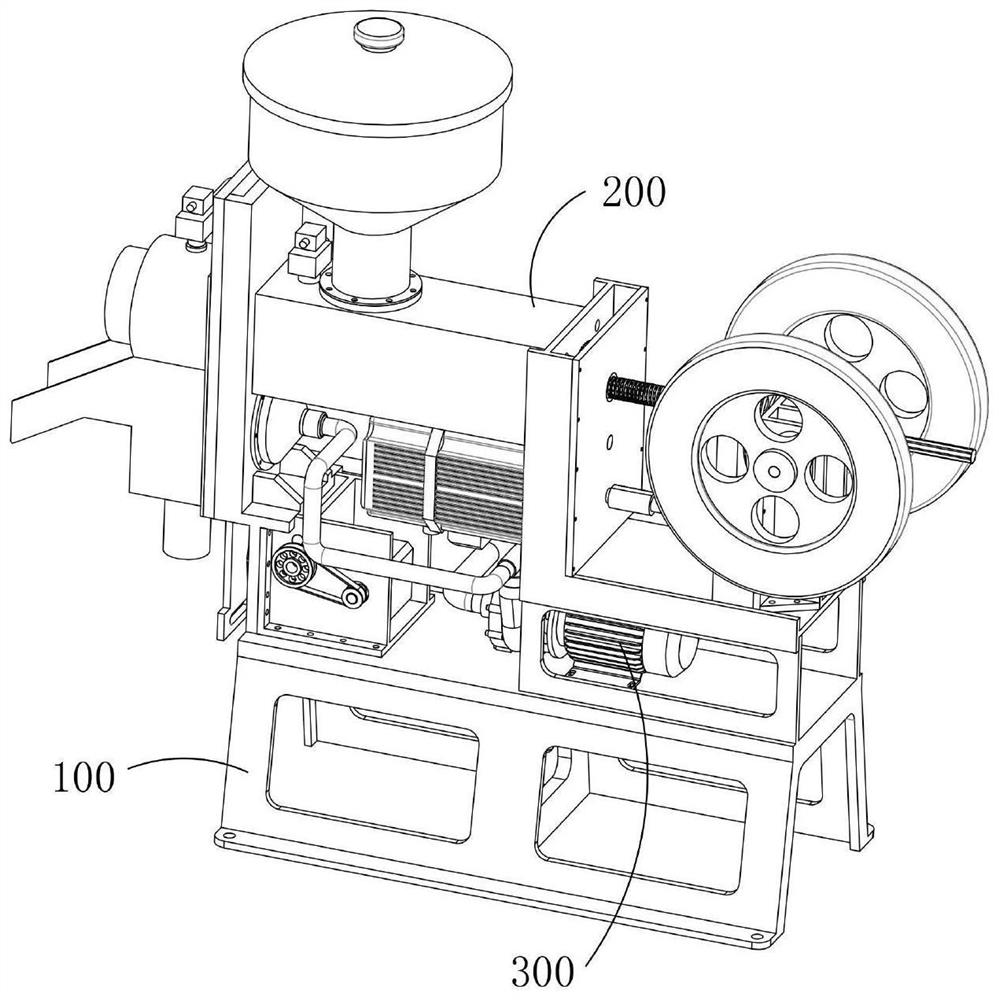

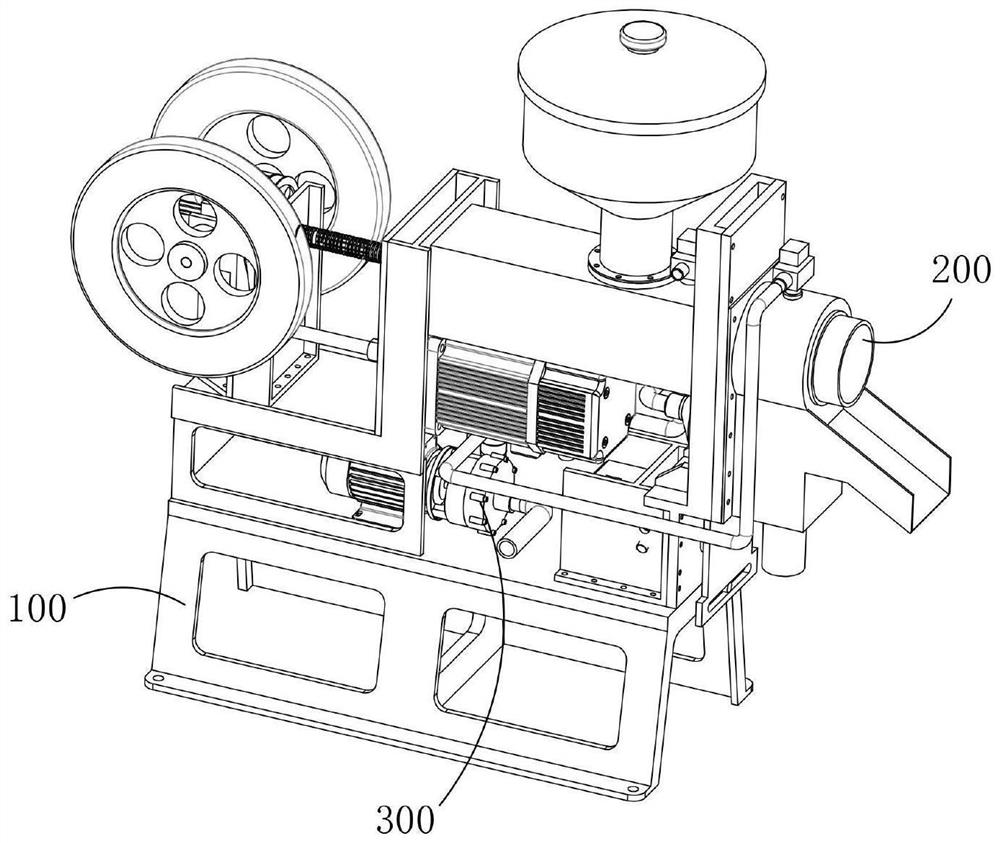

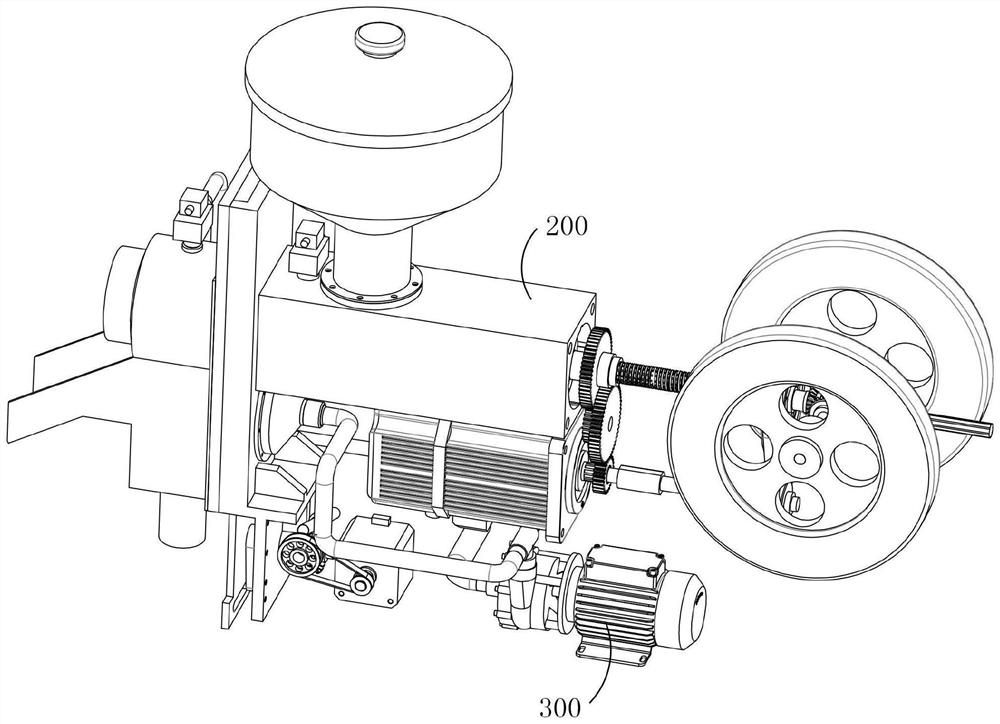

[0066] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0067] The compression molding method of household garbage, its steps are:

[0068] (1) Compression stage;

[0069] S1: The staff dumps domestic garbage into the garbage compression device 200 installed on the installation frame body 100;

[0070] After the staff dumps the domestic waste into the funnel 213, the domestic waste passes through the funnel 213 and the feeding hole 2121 in turn, and then guides and falls into the compression pipe 212;

[0071] S2: the compression mechanism 220 starts to run;

[0072] After the domestic garbage falling into the compression pipe 212 reaches the actual set value, the power assembly starts to run and drives the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com