A dual-sludge biologically enhanced sewage treatment device

A sewage treatment device and bio-augmentation technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, return water treatment, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

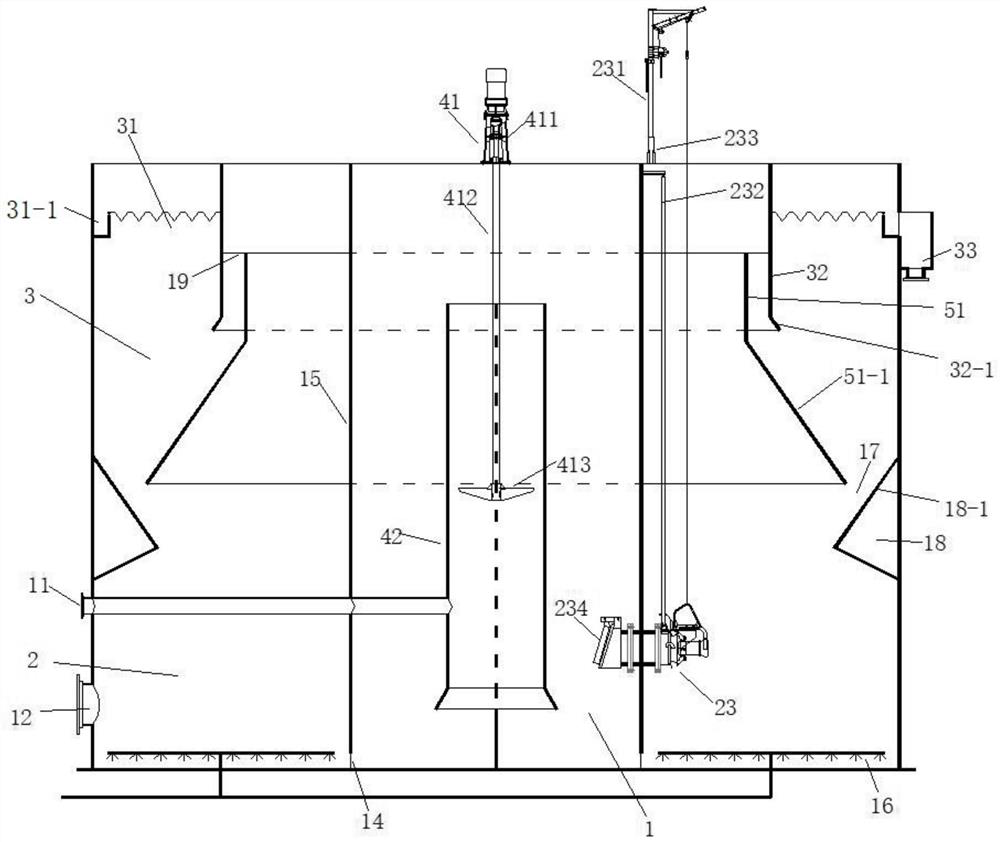

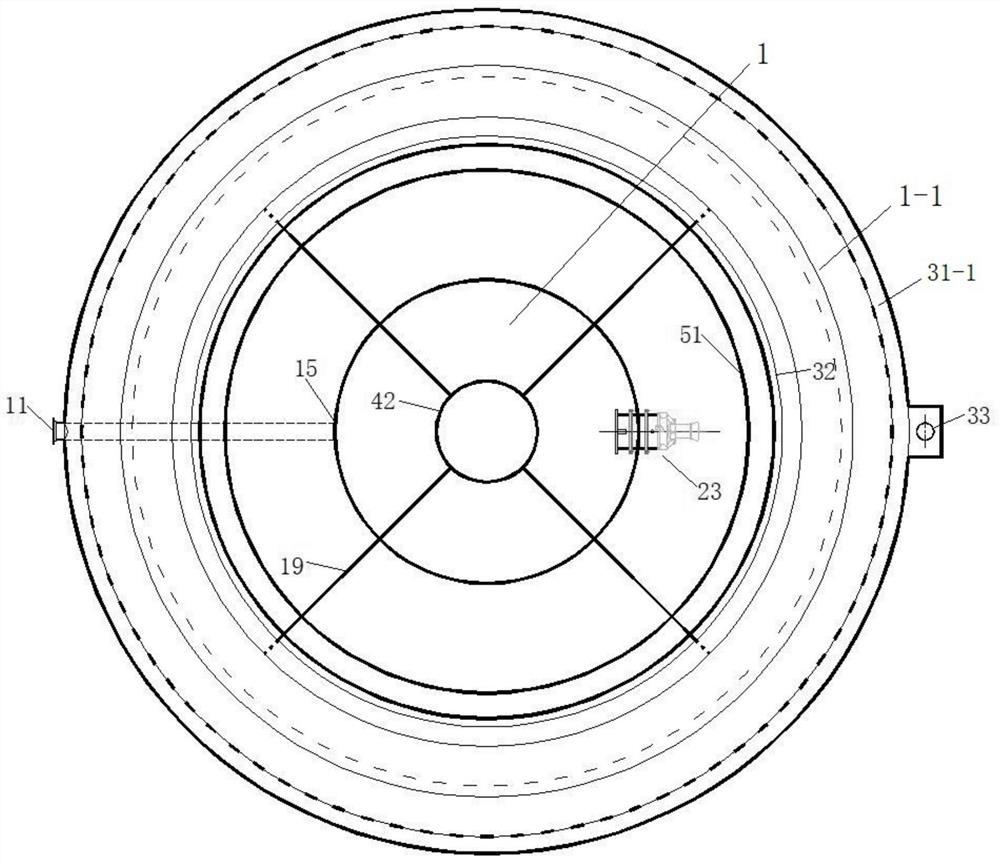

[0033] Such as Figure 1-2 As shown, it is a kind of double-sludge method bio-enhanced sewage treatment device provided in this embodiment. The device is cylindrical, including an anoxic zone 1 formed by a central cylinder 15 in the center, and an aerobic / aerobic zone around the anoxic zone 1 Precipitation zone 1-1, aerobic / precipitation zone 1-1 includes aerobic zone 2 with water inlet pipe 11 opening, precipitation zone 3 located on the upper part of aerobic zone 2, and the device also includes connecting anoxic zone 1 and aerobic zone The bottom flow hole 14 of 2, the submersible internal reflux pump 23 that returns the sewage nitrification liquid in the aerobic zone 2 to the anoxic zone 1; The inner compartment 51 of 51-1, the outer compartment 32 with the horn-shaped second annular guide plate 32-1 and the annular mud guide cone 18 fixed on the device shell are separated, and the first annular guide plate 51-1 of the inner compartment 51 Located on the top of the inwar...

Embodiment 2

[0048] The difference between this embodiment and embodiment 1 is that the volume ratio of the anoxic zone 1 to the aerobic zone 2 is 1:5, and the surface load of the precipitation zone 3 is 2.0m 3 / m 2 h, the volume load of the device when denitrification / nitrification biological denitrification is 2.0Kg BOD 5 / m 3 d.

[0049] The aeration system 16 is located at the bottom of the aerobic zone 2 and arranged circularly along the aerobic zone 2. The aeration system 16 adopts an aeration pan.

[0050] The width of the mud tank 17 is 100mm, and the flow velocity of the mixed sewage in the device through the mud tank 17 is 0.02m / s; the distance between the guide tube 42 and the top of the device shell is 600mm, and the diameter of the guide tube 42 is 110mm; the sedimentation area The distance between the annular overflow weir 31 of 3 and the top of the device is 300mm, the water outlet 33 is lower than the annular overflow weir 31, and a water collection tank 31-1 is formed b...

Embodiment 3

[0052] The difference between this embodiment and embodiment 1 is that the volume ratio of the anoxic zone 1 to the aerobic zone 2 is 1:2, and the surface load of the precipitation zone 3 is 0.6m 3 / m 2 h, the volume load of the device when denitrification / nitrification biological denitrification is 0.4Kg BOD 5 / m 3 d.

[0053] The aeration system 16 is located at the bottom of the aerobic zone 2 and arranged circularly along the aerobic zone 2, and the aeration system 16 adopts diffuse aerators.

[0054] The width of the mud tank 17 is 300mm, and the flow velocity of the mixed sewage in the device to pass the mud tank 17 is 0.2m / s; the distance between the guide tube 42 and the top of the device shell is 1000mm, and the diameter of the guide tube 42 is 150mm; the sedimentation area The distance between the annular overflow weir 31 of 3 and the top of the device is 700mm, the water outlet 33 is lower than the annular overflow weir 31, and a water collection tank 31-1 is for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com