Clean production process of hydrogenated azobenzene

A hydrogenated azobenzene, clean production technology, applied in the direction of organic chemistry, hydrazine preparation, etc., can solve the problems of incomplete reaction, large amount of waste water, large safety risk, etc., and achieve the effect of saving alkali consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

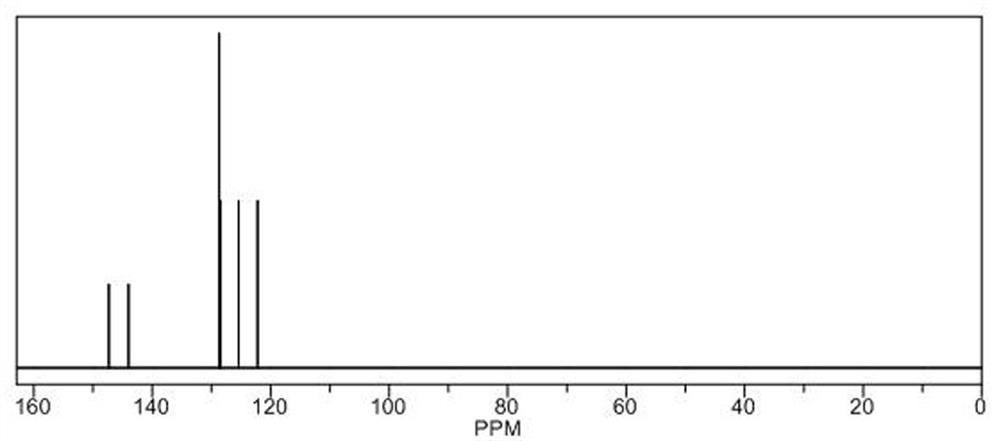

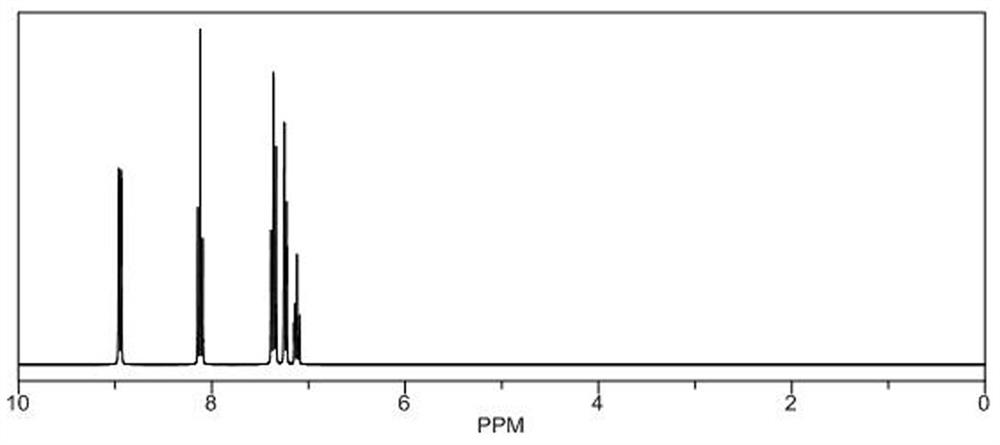

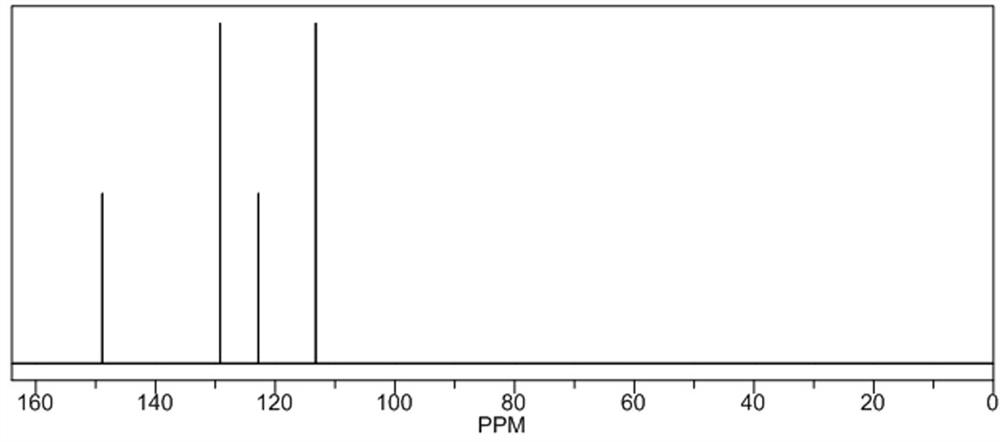

Image

Examples

Embodiment 1

[0032] A clean production process of hydroazobenzene, comprising the steps of:

[0033] 1) In a 50ml four-necked reaction flask equipped with a stirrer, condenser and heater, add 16.00g of 25% sodium hydroxide solution, 2000.13g of polyethylene glycol, 0.03g of 1,4-naphthoquinone, and nitrobenzene 6.40g (0.052mol), slowly heat up to 65°C with stirring, add 1.91g (0.039mol) of hydrazine hydrate dropwise, dropwise for 1 hour, then raise the temperature to 70°C for 5 hours, and the peak of nitrobenzene disappears as detected by liquid chromatography , cooled to 18°C, kept warm for 4 hours, suction filtered, washed with water, and the filter cake was azobenzene oxide;

[0034] 2) Weigh 6.00g of azobenzene oxide, 7.80g of 5% sodium hydroxide solution, 2000.30g of polyethylene glycol, and 2.40g of hydrazine hydrate into a 25ml four-necked reaction flask equipped with a stirrer, condenser tube and heater After raising the temperature to 65°C, add 0.03g of Raney nickel, react for 4 h...

Embodiment 2

[0037] A clean production process of hydroazobenzene, comprising the steps of:

[0038] 1) Add 22.40 g of 20% sodium hydroxide solution, 15000.32 g of polyethylene glycol, 0.13 g of 1,4-naphthoquinone, and nitrobenzene 6.40g (0.052mol), slowly heat up to 40°C with stirring, add 2.55g (0.052mol) of hydrazine hydrate dropwise, dropwise for 1.5h, then heat up to 45°C and react for 10 hours, the peak of nitrobenzene is detected by liquid chromatography disappear, lower the temperature to 18°C, keep warm for 4 hours, filter with suction, wash with water, and the filter cake is azobenzene oxide;

[0039] 2) Weigh 6.00g of azobenzene oxide, 8.00g of 3% sodium hydroxide solution, 15000.48g of polyethylene glycol, and 3.00g of hydrazine hydrate into a 25ml four-necked reaction flask equipped with a stirrer, condenser tube and heater After raising the temperature to 55°C, add 0.12g of Raney nickel, react for 6 hours, drop to 20°C, filter with suction, wash with water, and dry in vacuum...

Embodiment 3

[0042] A clean production process of hydroazobenzene, comprising the steps of:

[0043] 1) In a 50ml four-necked reaction flask equipped with a stirrer, condenser and heater, add 32.00g of 15% sodium hydroxide solution, 8000.64g of polyethylene glycol, 0.32g of 1,4-naphthoquinone, and nitrobenzene 6.40g (0.052mol), slowly heat up to 85°C with stirring, add 3.04g (0.062mol) of hydrazine hydrate dropwise, dropwise for 2 hours, then heat up to 90°C for 3 hours, and the peak of nitrobenzene disappears as detected by liquid chromatography , cooled to 18°C, kept warm for 4 hours, suction filtered, washed with water, and the filter cake was azobenzene oxide;

[0044] 2) Weigh 6.00g of azobenzene oxide, 10.80g of 1% sodium hydroxide solution, 8000.60g of polyethylene glycol, and 3.60g of hydrazine hydrate into a 25ml four-necked reaction flask equipped with a stirrer, condenser tube and heater After raising the temperature to 85°C, add 0.30g of Raney nickel, react for 3 hours, lower ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com