EVA/PEBAX supercritical foaming composite shoe material and preparation method thereof

A supercritical technology for footwear, applied in applications, footwear, apparel, etc., can solve the problems of inability to distribute evenly, low melting point, affecting the quality of supercritical foamed composite footwear materials, etc., and achieve far-reaching application prospects and mechanical properties. Good, lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

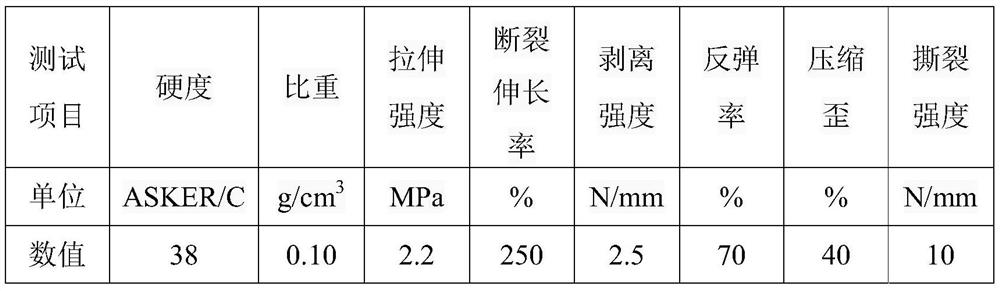

Examples

Embodiment 1

[0068] Embodiment 1 provides a kind of EVA / PEBAX supercritical foaming composite shoe material, by weight, the preparation raw material of described EVA / PEBAX supercritical foaming composite shoe material is: ethylene-vinyl acetate copolymer 30 parts , 10 parts of styrene-butadiene copolymer, 30 parts of thermoplastic PA12 polyether elastomer, 1 part of peroxide, 1.2 parts of nucleating agent, 5 parts of polyether grafted polyethylene maleic anhydride copolymer, stearic acid 1 part zinc;

[0069] The grade of the ethylene-vinyl acetate copolymer is LG EVA EA28400, the content of vinyl acetate (VO) is 28wt%, and the melt mass flow rate (190°C, 2.16kg) is 400g / 10min, purchased from Korea LG Chemical Company;

[0070] The styrene / butadiene block ratio in the styrene-butadiene copolymer is 40 / 60, the brand is SBS YH-792, purchased from Baling Branch of China Petroleum & Chemical Corporation;

[0071] The trade mark of described thermoplastic PA12 polyether elastomer is 7233SP 0...

Embodiment 2

[0085] Embodiment 2 provides a kind of EVA / PEBAX supercritical foaming composite shoe material, by weight, the preparation raw material of described EVA / PEBAX supercritical foaming composite shoe material is: ethylene-vinyl acetate copolymer 40 parts , 20 parts of styrene-butadiene copolymer, 40 parts of thermoplastic PA12 polyether elastomer, 3 parts of peroxide, 1.6 parts of nucleating agent, 8 parts of polyether grafted polyethylene maleic anhydride copolymer, stearic acid 3 parts of zinc;

[0086] Described ethylene-vinyl acetate copolymer is with embodiment 1;

[0087] Described styrene-butadiene copolymer is with embodiment 1;

[0088] Described thermoplastic PA12 polyether elastomer is with embodiment 1;

[0089] The peroxide is bis-tert-butylperoxycumene (CAS No. 2212-81-9);

[0090] Described nucleating agent is with embodiment 1;

[0091] Described polyether graft polyethylene maleic anhydride copolymer is with embodiment 1;

[0092] The CAS number of the zinc s...

Embodiment 3

[0098] Embodiment 3 provides a kind of EVA / PEBAX supercritical foaming composite shoe material, by weight, the preparation raw material of described EVA / PEBAX supercritical foaming composite shoe material is: ethylene-vinyl acetate copolymer 35 parts , 15 parts of styrene-butadiene copolymer, 35 parts of thermoplastic PA12 polyether elastomer, 2 parts of peroxide, 1.4 parts of nucleating agent, 6 parts of polyether grafted polyethylene maleic anhydride copolymer, stearic acid Zinc 2 parts;

[0099] Described ethylene-vinyl acetate copolymer is with embodiment 1;

[0100] Described styrene-butadiene copolymer is with embodiment 1;

[0101] Described thermoplastic PA12 polyether elastomer is with embodiment 1;

[0102] The peroxide is bis-tert-butylperoxycumene (CAS No. 2212-81-9);

[0103] Described nucleating agent is with embodiment 1;

[0104] Described polyether graft polyethylene maleic anhydride copolymer is with embodiment 1;

[0105] The CAS number of the zinc stea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt mass flow rate | aaaaa | aaaaa |

| Vicat softening temperature | aaaaa | aaaaa |

| Melt mass flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com